Reverse hedging internal combustion engine

An internal combustion engine and reverse pairing technology, applied in mechanical equipment, engine components, engine control, etc., can solve problems such as insufficient oxygen, short service life, damage to cylinder head gaskets, etc., achieve strong combustion, lower production costs, The effect of increasing the mechanical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

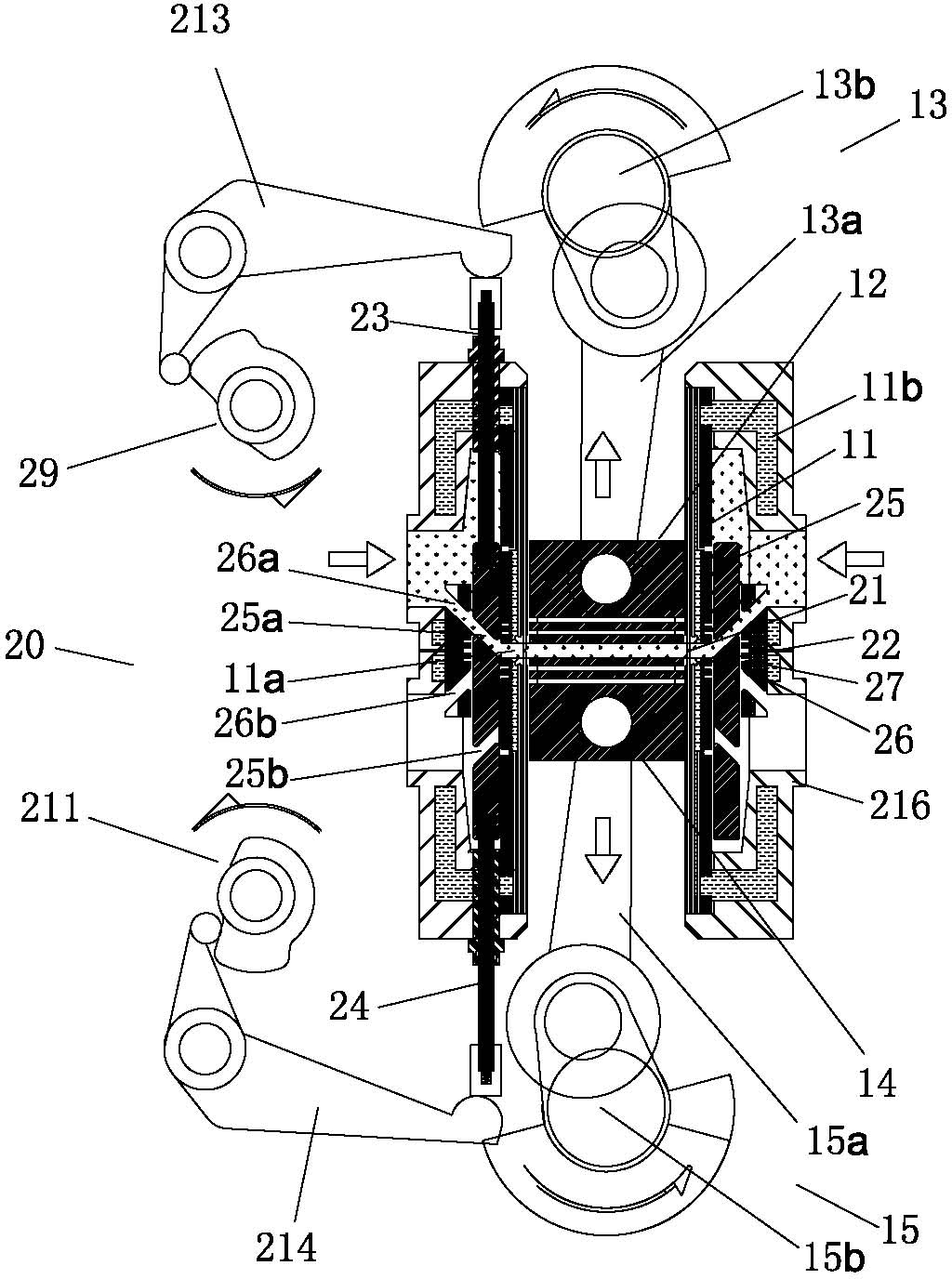

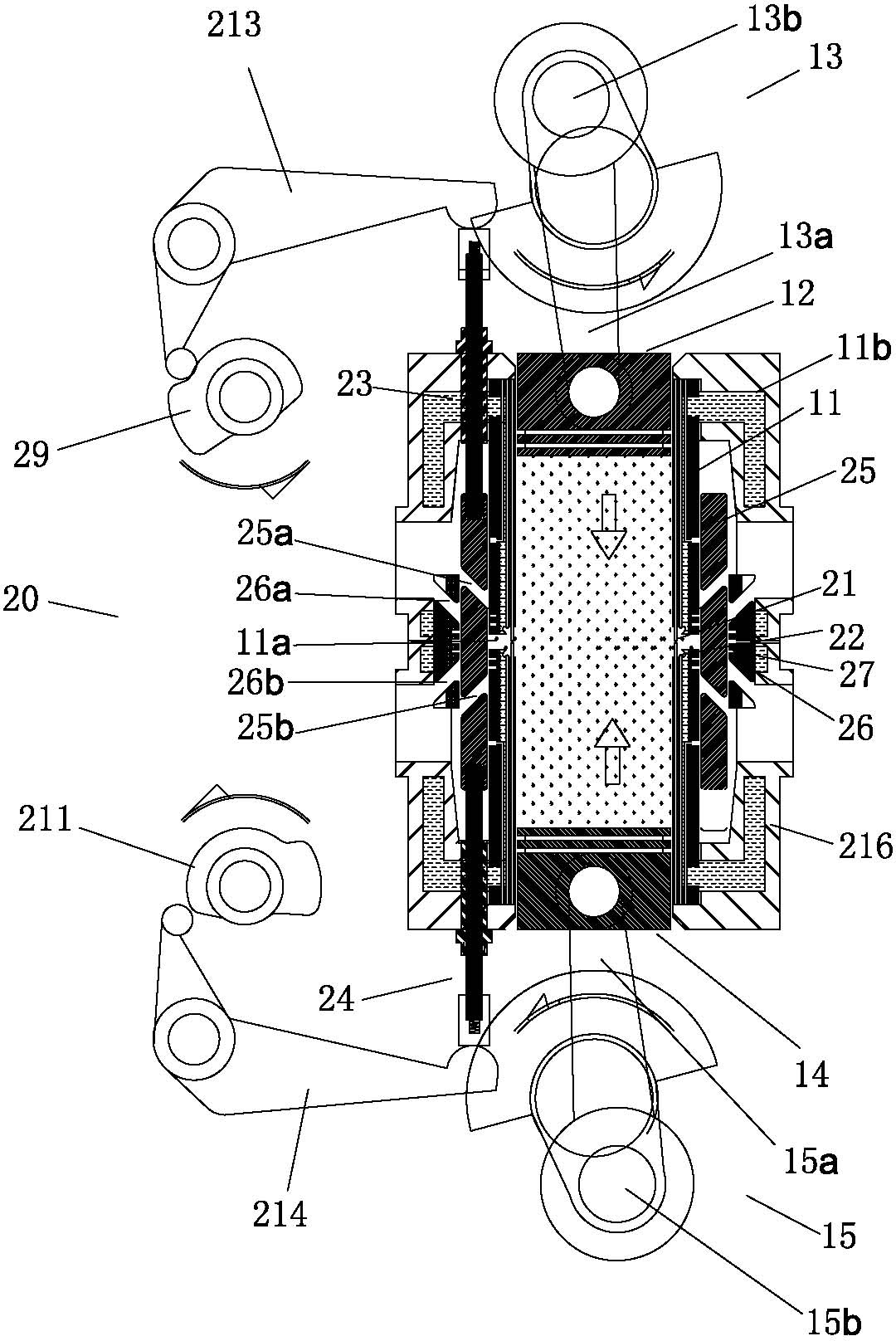

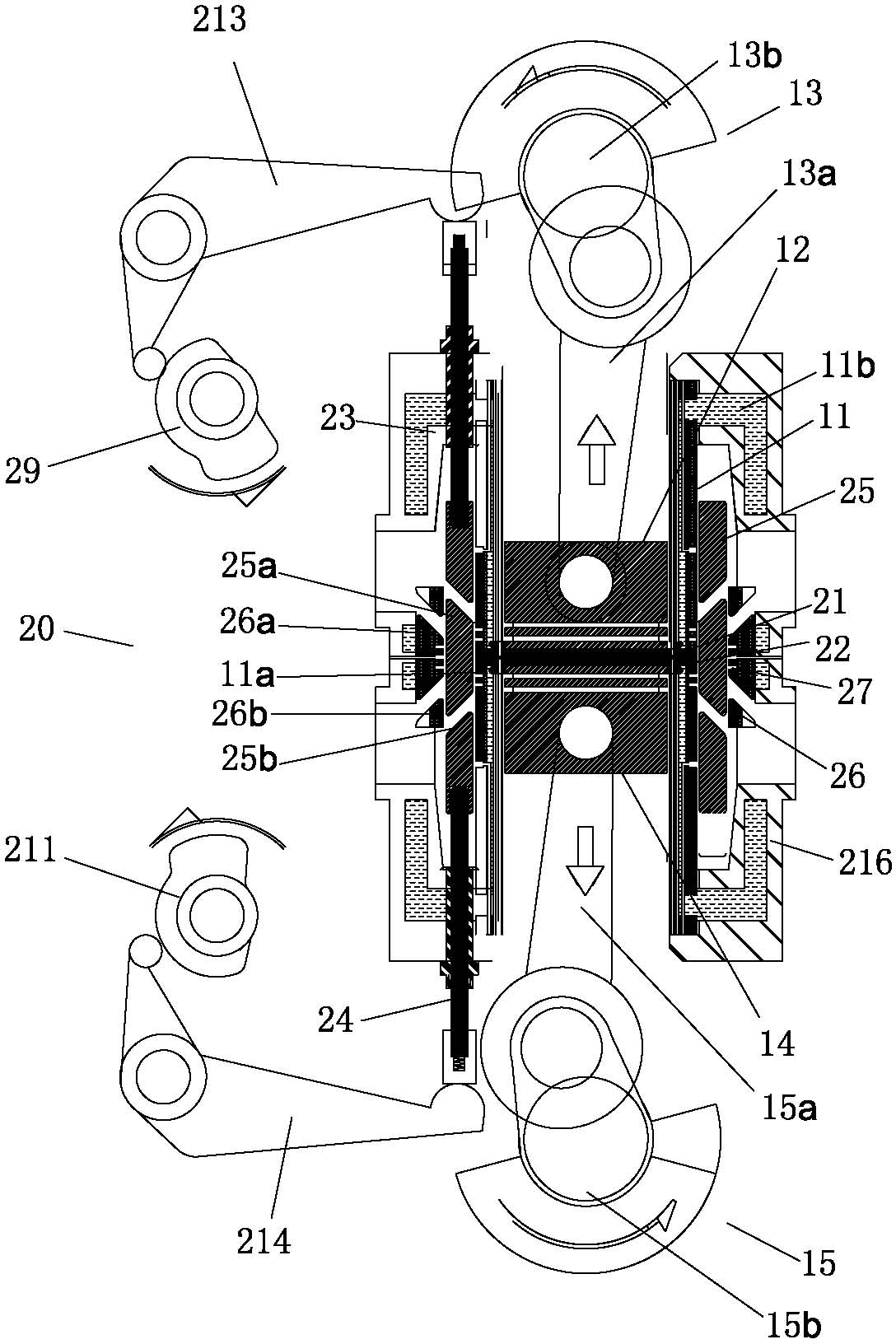

[0030] Such as Figure 1-6 Shown, a kind of reverse hedging internal combustion engine, it comprises internal combustion engine cylinder liner 11, has air inlet 11a in the middle part of internal combustion engine cylinder liner 11, and the position of air intake port 11a of internal combustion engine cylinder liner 11 is provided with control air intake and ignition The air intake ignition device 20; the left side of the air intake 11a position of the internal combustion engine cylinder liner 11 is provided with a left piston 12 and a left crank mechanism 13 from the inside to the outside, and the right side of the air intake 11a position of the internal combustion engine cylinder liner 11 is provided with Right piston 14 and right crank mechanism 15 are arranged from inside to outside, left piston 12, left crank mechanism 13 and right piston 14, right crank mechanism 15 are symmetrically arranged on both sides of air inlet 11a, left crank mechanism 13 and right crank mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com