Engine tail gas diluting and cooling device based on Bernoulli law and debugging method and adjusting method

A technology of cooling device and engine, which is applied to exhaust devices, engine components, combustion engines, etc., can solve the problems of reducing the exhaust temperature to below the risk factor, dense personnel exchanges, and exhaust temperature restrictions, and achieves a simple and convenient debugging method. , The effect of low exhaust temperature and increasing suction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

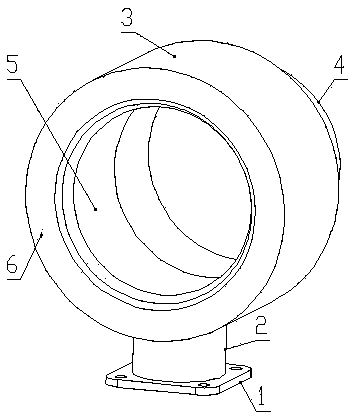

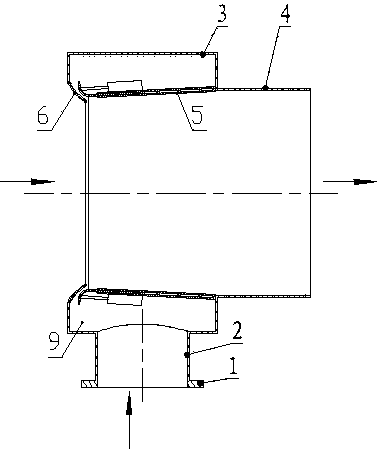

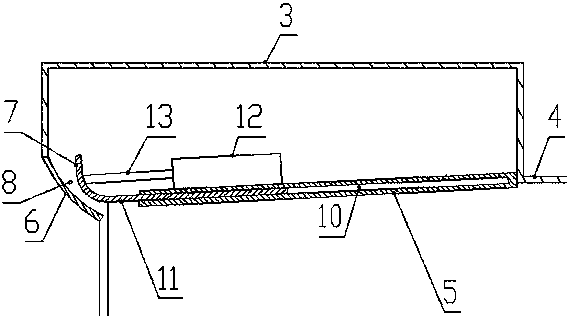

[0055] like Figure 1 to Figure 4 As shown, the engine exhaust dilution and cooling device based on Bernoulli's law of the present invention includes a dilution box 3, the middle part of the side wall of the dilution box 3 is connected with a cooling pipe 4 for exhaust exhaust, and the dilution box 3 is provided with a cooling pipe 4 that communicates with the cooling pipe 4. The diffuser 5 is inwardly directed toward the center of the dilution tank 3, and the side wall of the dilution tank 3 is connected inwardly with a suction port 6 communicating with the atmosphere. The vertical section of the suction port 6 is a horn with a large outside and a small inside. shape; the suction port 6 and the diffuser tube 5 are respectively connected on the opposite side walls of the dilution box 3, and the connection between the suction port 6 and the dilution box 3 is the root of the suction port 6;

[0056] One end of the diffuser 5 facing the suction port 6 is connected with a bell mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com