Mono screw pump with stirring and drainage functions for reaction kettle

A single-screw pump and reactor technology, applied in the direction of axial flow pumps, pumps, non-variable pumps, etc., can solve the problem of affecting the uniformity of high-viscosity medium reaction, slow downward flow of high-viscosity medium, and long residence time. and other problems, to achieve stable delivery, ensure uniformity of reaction, and uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

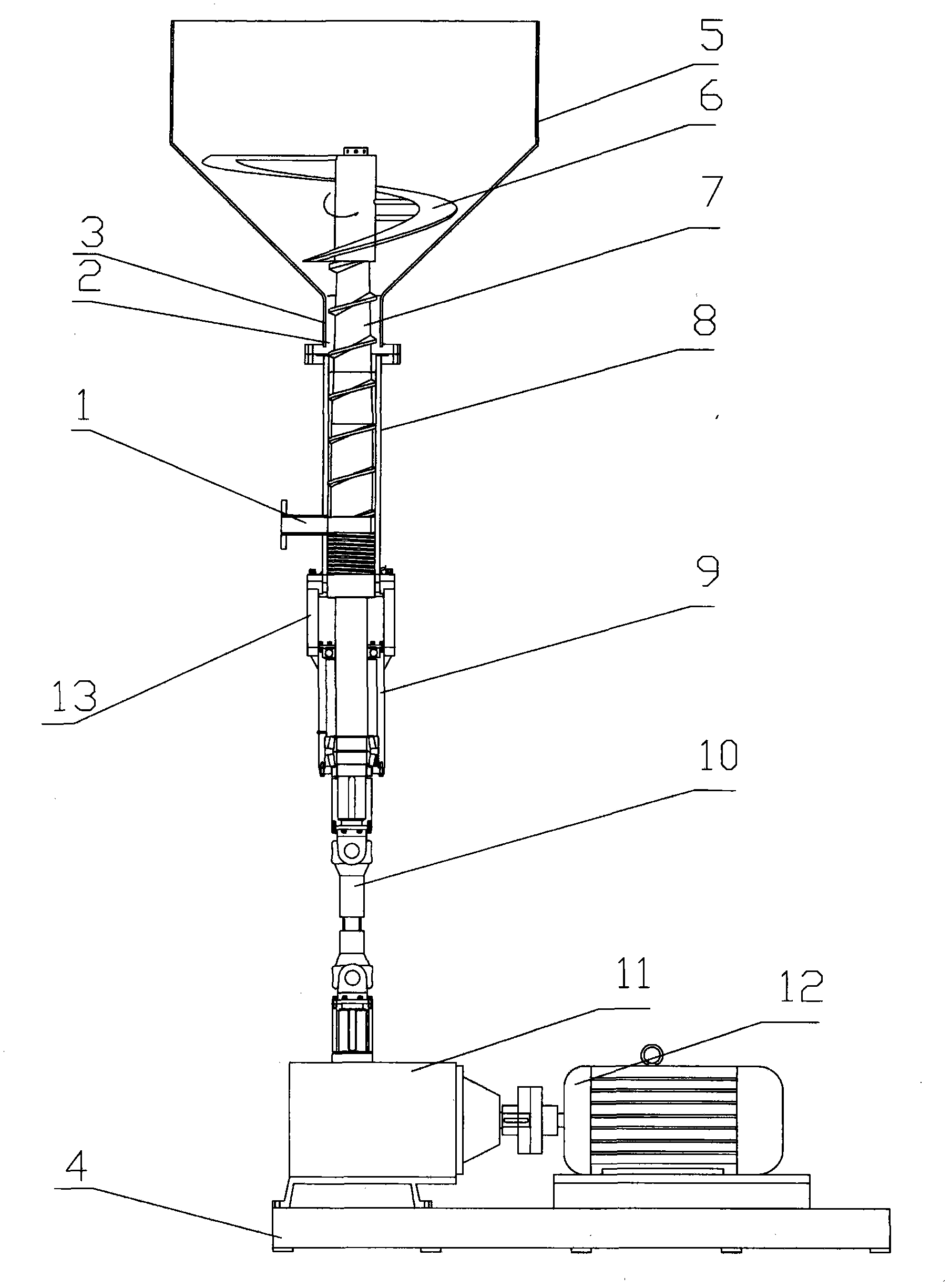

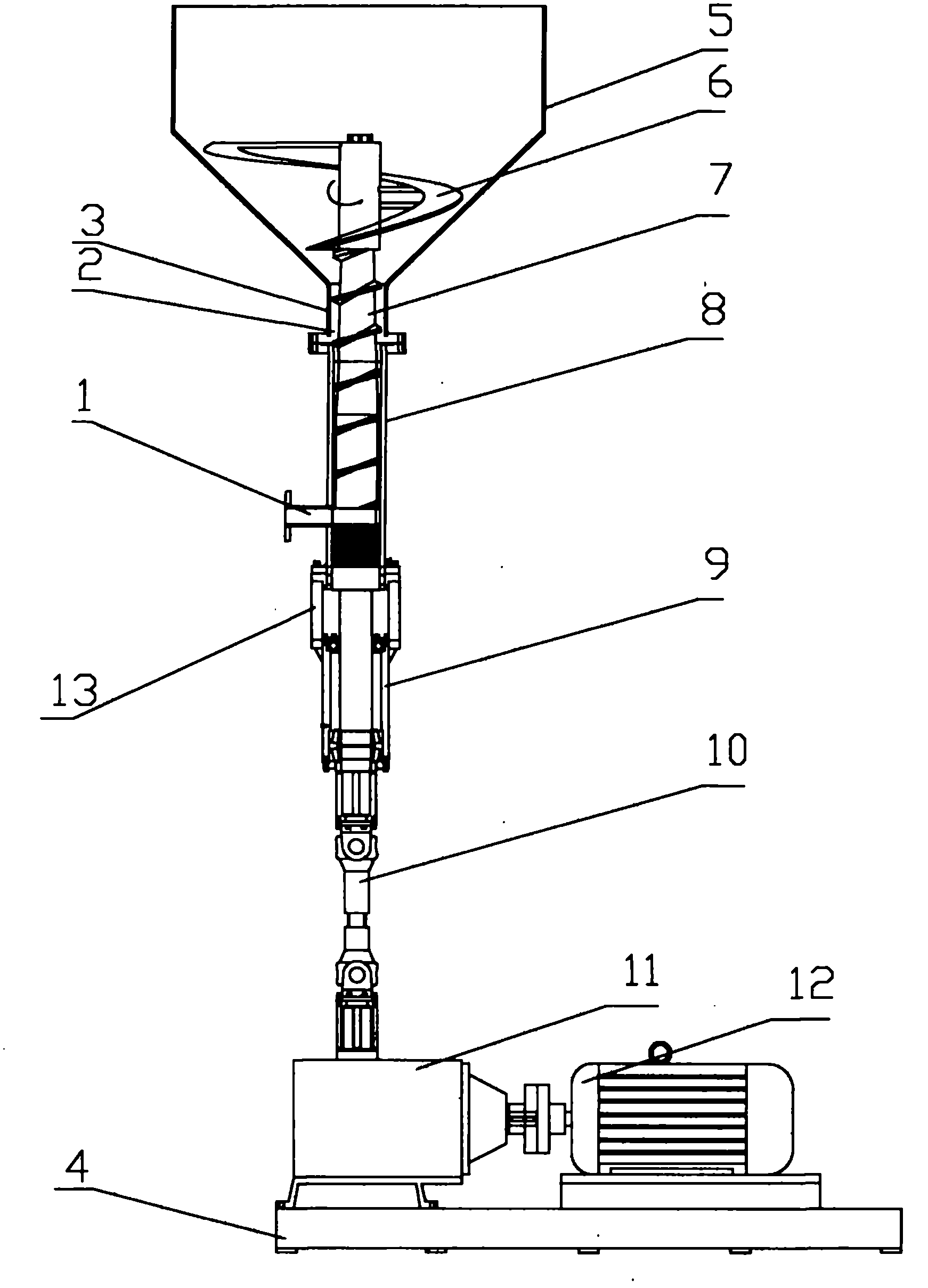

[0025] A single-screw pump for a reactor with the function of stirring and draining as shown in the accompanying drawings, installed vertically, including a pump base 4, a bushing 8, a screw 7, and screw drive components. The screw driving part includes a driving motor 12 and its reduction box 11 , a universal coupling 10 , and a coupling body 13 and a bearing seat 9 connecting the screw 7 and the universal coupling 10 .

[0026] The bushing 8 is a barrel with a double-layer structure, including an inner barrel and a jacket with a heating and cooling structure. The jacket is provided with an oil inlet pipe and an oil outlet pipe.

[0027] The screw 7 is arranged in the cavity of the inner cylinder and is driven to rotate by the driving part. The depth of the groove of the screw gradually becomes shallower from deep to shallower, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com