Preparation method of cerium-based mixed rare earth polishing powder

A technology of rare earth polishing powder and mixed rare earth, which is applied in the direction of polishing composition containing abrasives, etc. It can solve the problems of complex mixing process of fluoride and oxide, complex post-treatment process, secondary sintering of particles, etc., and achieve polishing accuracy Easy to control, low cost, and the effect of ensuring the uniformity of fluorination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

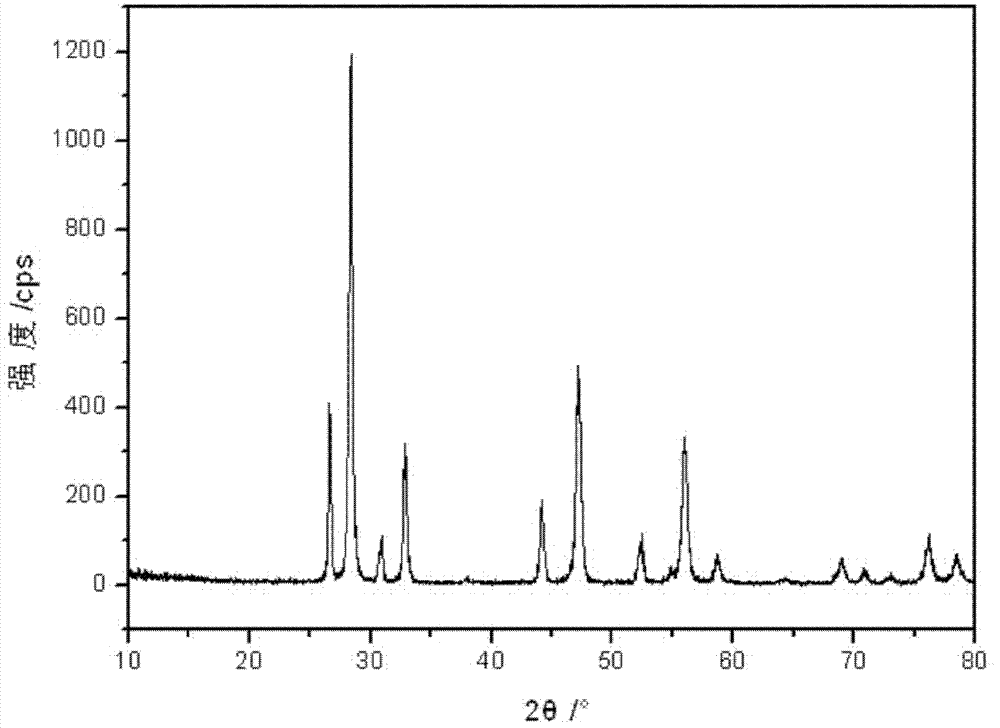

Image

Examples

Embodiment 1

[0038] In rare earth chloride, the mass ratio of each component is:

[0039] The total amount of rare earth REO is 45%, cerium oxide is 70%, lanthanum oxide is 29.95%, and the balance is 0.05% of praseodymium oxide;

[0040] Mix the above 1000kg rare earth chloride with 2000kg water, add 180kg30% hydrogen peroxide, 142kg40% fluosilicic acid and 20kg98% sulfuric acid in sequence. After fully stirring, heat to 60°C, slowly add 10% ammonium bicarbonate aqueous solution until the pH at the end point is 6.5, and keep warm for 12 hours. After centrifugal dehydration, dry at 100°C for 15 hours to obtain partially fluorinated rare earth carbonate.

[0041] Mix the above 1000kg rare earth chloride with 2000kg water, stir well and heat to 60°C, slowly add 10% ammonium bicarbonate aqueous solution until the pH at the end is 6.5, and keep warm for 12h. After centrifugal dehydration, dry at 100°C for 15 hours to obtain rare earth carbonate.

[0042] Partially fluorinated rare earth carb...

Embodiment 2

[0044] In rare earth chloride, the mass ratio of each component is:

[0045] The total amount of rare earth REO is 45%; cerium oxide is 60%; lanthanum oxide is 34%; praseodymium oxide is 6%;

[0046]Mix the above 1000kg rare earth chloride with 2000kg water, add 225kg of 30% hydrogen peroxide, 214kg of 40% fluosilicic acid and 40kg of 98% sulfuric acid. After fully stirring, heat to 80°C, slowly add 15% ammonium bicarbonate aqueous solution until the pH value at the end is 7, and keep warm for 5 hours. After centrifugal dehydration, dry at 200°C for 10 hours to obtain partially fluorinated rare earth carbonate.

[0047] Mix the above-mentioned 1000kg rare earth chloride with 2000kg water, stir well and heat to 60°C, slowly add 10% ammonium bicarbonate aqueous solution until the pH value at the end is 7, and keep warm for 5h. After centrifugal dehydration, dry at 200°C for 10 hours to obtain rare earth carbonate.

[0048] Partially fluorinated rare earth carbonate and rare e...

Embodiment 3

[0050] In rare earth chloride, the mass ratio of each component is:

[0051] The total amount of rare earth REO is 45%; cerium oxide is 60%; lanthanum oxide is 36% and praseodymium oxide is 4%;

[0052] Mix the above 1000kg rare earth chloride with 2000kg water, add 210kg30% hydrogen peroxide, 178kg40% fluosilicic acid and 30kg sulfuric acid with a mass concentration of 98%. After fully stirring, heat to 70° C., slowly add an aqueous ammonium bicarbonate solution with a mass concentration of 12%, until the pH at the end point is 6.8, and keep warm for 8 hours. After centrifugal dehydration, dry at 160°C for 12 hours to obtain partially fluorinated rare earth carbonate.

[0053] Mix the above 1000kg rare earth chloride with 2000kg water, stir well and heat to 70°C, slowly add ammonium bicarbonate aqueous solution with a mass concentration of 12%, until the pH at the end is 6.8, and keep warm for 8h. After centrifugal dehydration, dry at 160°C for 12 hours to obtain rare earth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com