Cerium-based mixed rare earth polishing powder and preparation method thereof

A technology of mixing rare earth and polishing powder, which is applied in chemical instruments and methods, polishing compositions containing abrasives, and other chemical processes, can solve problems such as difficult dehydration, polishing scratches, uneven fluorination reactions, etc., to ensure Uniformity of fluorination reaction, ensuring uniformity of fluorination, and easy polishing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of cerium-based mixed rare earth polishing powder of the present invention, it comprises the steps:

[0036] (1) Preparation of partial fluorination of rare earth carbonate: mix rare earth carbonate with water for beating, after ball milling, heat to 30-50°C, add inorganic acid to pH 3-4, then add diluted fluorinating agent, After fully stirring, adjust the pH value to 6.5-7 with ammonium bicarbonate solution, dehydrate and dry after holding for a certain period of time, and obtain a partially fluorinated rare earth carbonate mixture;

[0037] (2) mixing: mixing the rare earth fluorocarbonate mixture obtained above with the corresponding rare earth carbonate;

[0038] (3) roasting: the above-mentioned mixed product is roasted at high temperature to obtain a rare earth polishing powder precursor;

[0039] (4) Pulverization and classification: the rare earth polishing powder precursor is pulverized and classified to obtain cerium-based mixed rare e...

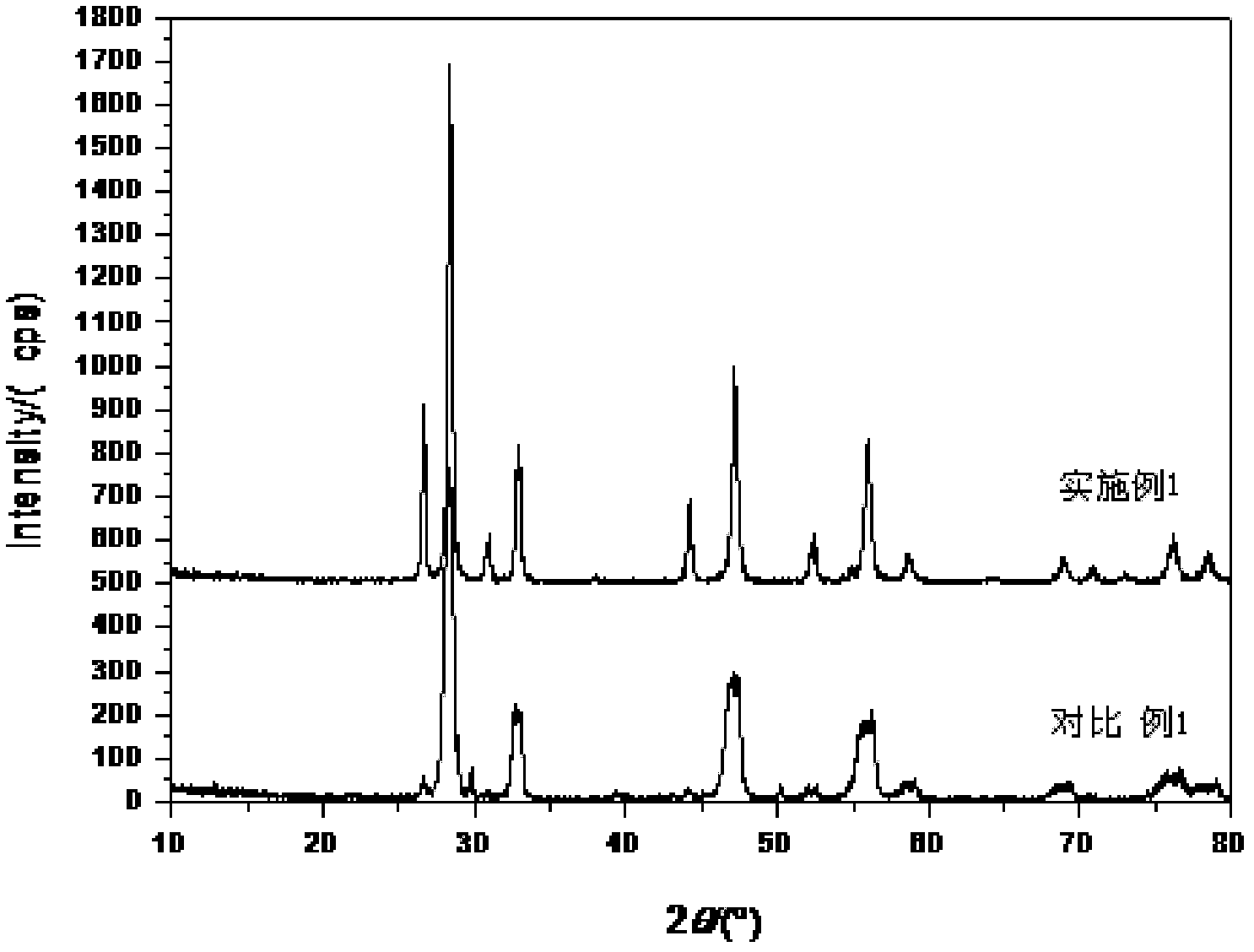

Embodiment 1

[0044]Mix 1000kg of lanthanum cerium carbonate with 650kg of water, ball mill for 2 hours, heat to 30°C, and add nitric acid to pH 3 while stirring. Mix 120kg of 40% hydrofluoric acid and 120kg of water, slowly add to the above feed solution, stir for 1h, add 10% ammonium bicarbonate solution until the pH value is 6.5, and dry at 160°C for 10h after centrifugal dehydration to obtain partial fluorination The rare earth carbonate mixture; mix the partially fluorinated rare earth carbonate mixture with 1000kg of lanthanum cerium carbonate, and roast at 1000°C for 5 hours to obtain the rare earth polishing powder precursor. After jet crushing and classification, the rare earth polishing powder described in the invention is obtained.

[0045] Laser particle size analyzer test results: D 50 =0.82μm, the grinding rate is 88%, and the surface roughness of the product is

Embodiment 2

[0047] Mix 1000kg lanthanum cerium praseodymium carbonate with 1500kg water, ball mill for 2 hours, heat to 50°C, and add phosphoric acid to pH 3 while stirring. Mix 80kg of 40% fluosilicic acid with 80kg of water, slowly add to the above feed solution, stir for 1h, add 15% ammonium bicarbonate solution until the pH value is 7, and dry at 160°C for 20h after centrifugal dehydration to obtain partial fluorination The mixture of rare earth carbonates; the partially fluorinated rare earth carbonate mixture is mixed with 800kg of lanthanum cerium carbonate and 200kg of cerium carbonate, and roasted at 1100°C for 4h to obtain the precursor of rare earth polishing powder. After jet crushing and classification, the invention described Rare earth polishing powder.

[0048] Laser particle size analyzer test results: D 50 =3.89μm, the grinding rate is 90%, and the surface roughness of the product is

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com