Embedded dual-layer rolling harmonious reducer

A harmonic reducer, embedded technology, applied in the direction of mechanical equipment, transmission devices, gear transmission devices, etc., can solve the problems affecting the service life of the bearings in the reducer, unstable working conditions, unstable output, etc., to achieve stable work , stable output and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

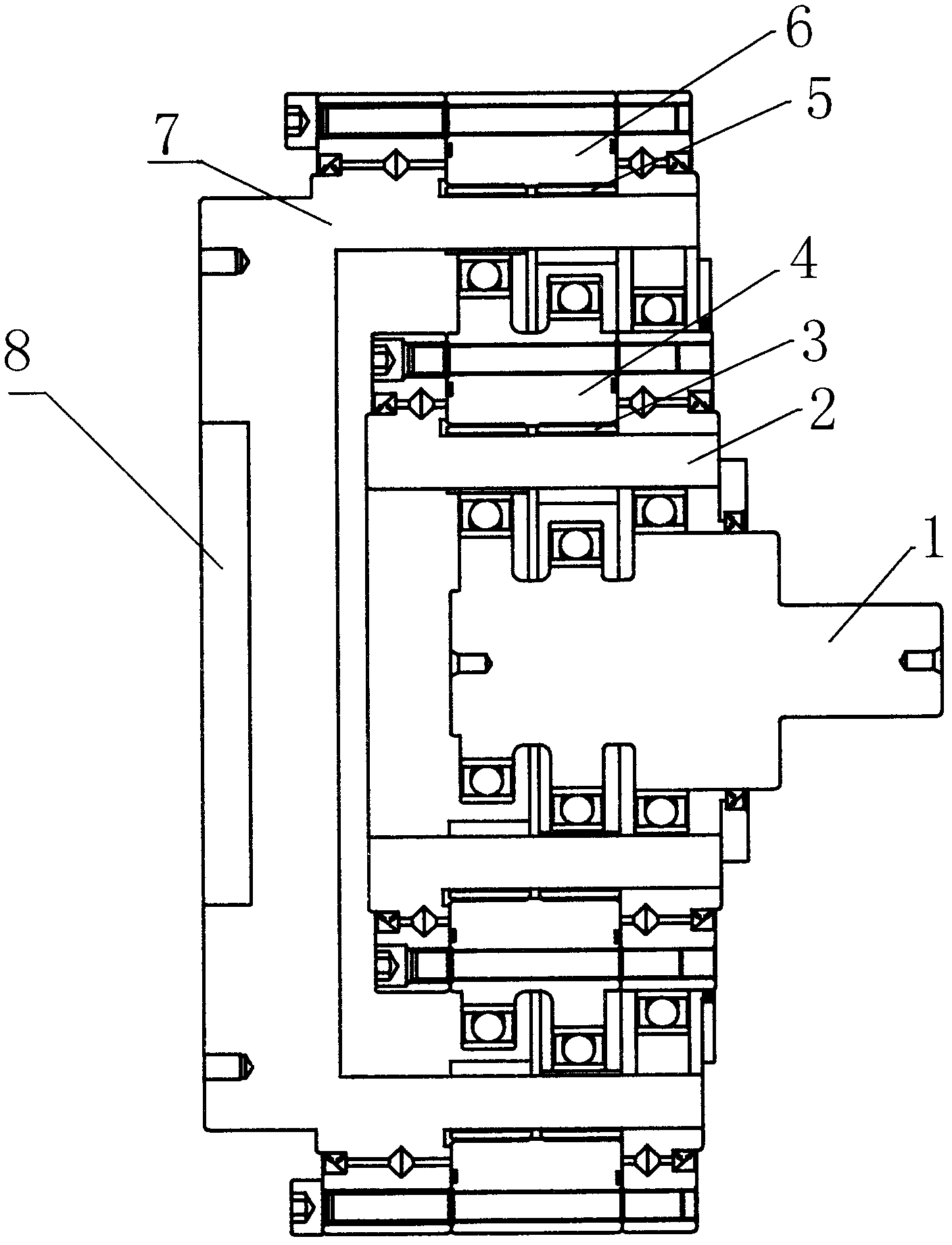

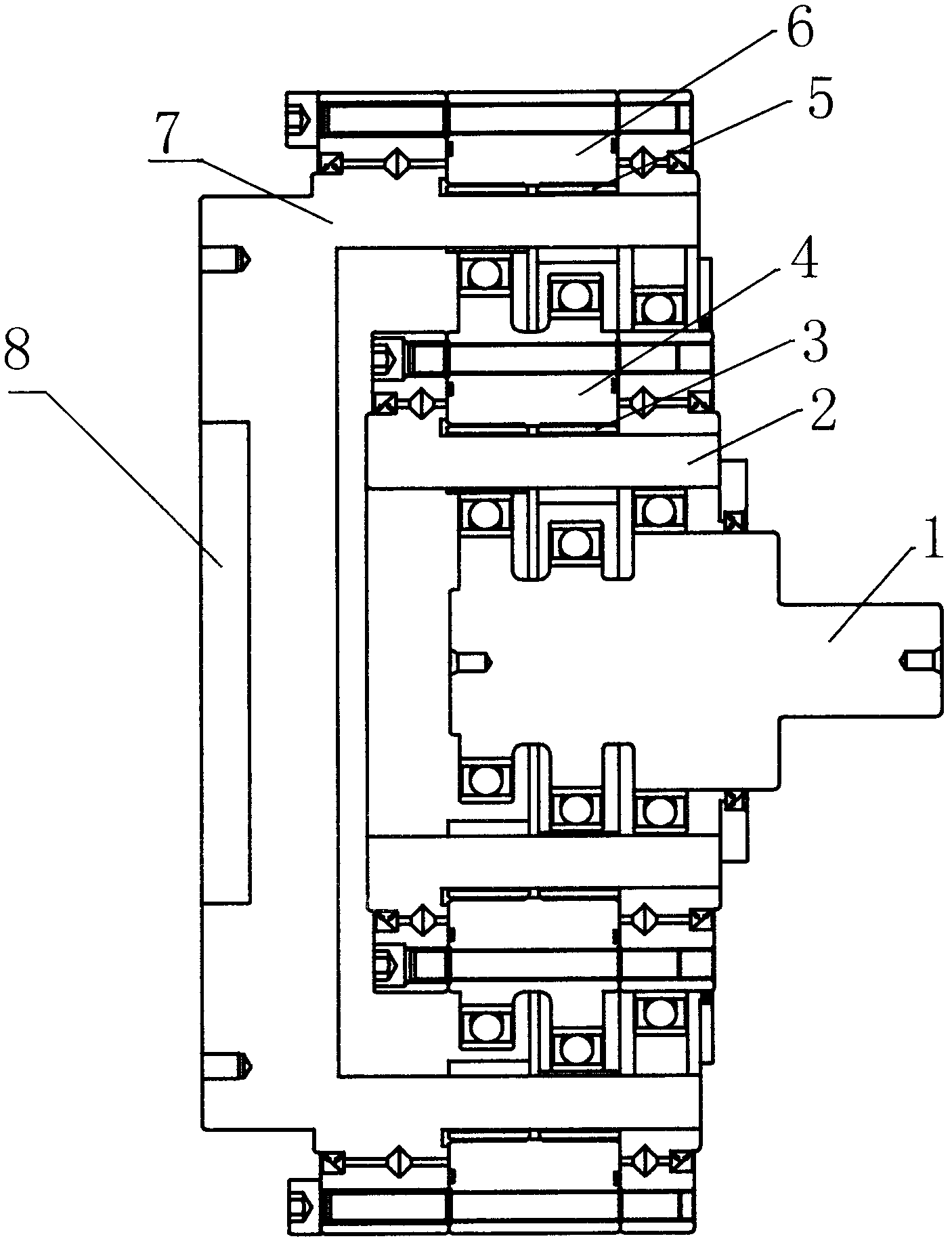

[0018] Such as figure 1 A mosaic double-layer rolling harmonic reducer shown includes an input end assembly 1, which is different in that a connecting shaft 2 is sheathed on the periphery of the input end assembly 1 used in the present invention. Moreover, in order to achieve the second-level deceleration, a nested double-layer layout is adopted. Specifically, in the present invention, an inner outer gear 4 is connected to the outer periphery of the connecting shaft 2 through an inner inner gear 3 assembly. At the same time, a bearing assembly is sheathed on the periphery of the inner outer gear 4 . In order to facilitate the connection of the entire reducer to be more compact and stable, the bearing assembly adopted in the present invention has a housing space distributed in the middle section, and an outer inner gear 5 assembly is sleeved around the housing space. Correspondingly, an outer outer gear 6 is sheathed on the periphery of the outer inner gear 5 assembly. As a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com