Double seal butterfly valve

A double seal and butterfly valve technology, applied in the direction of lift valve, valve detail, valve device, etc., can solve the problems of unsafe use, unreliable sealing, gas poisoning, etc., and achieve the effect of improving safety and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

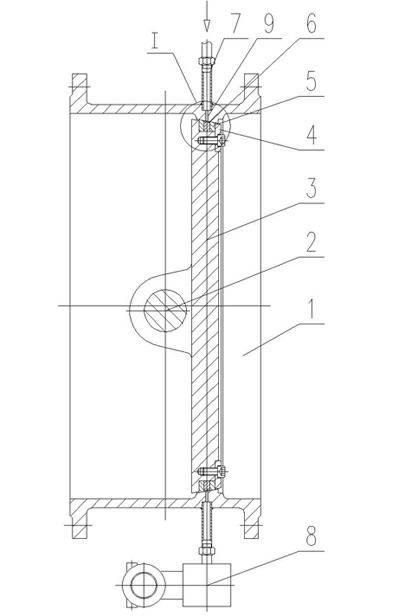

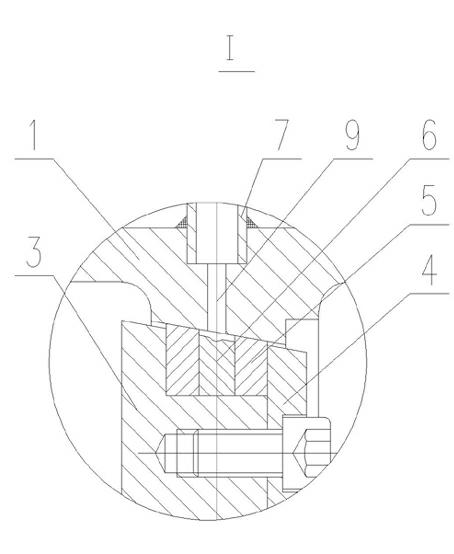

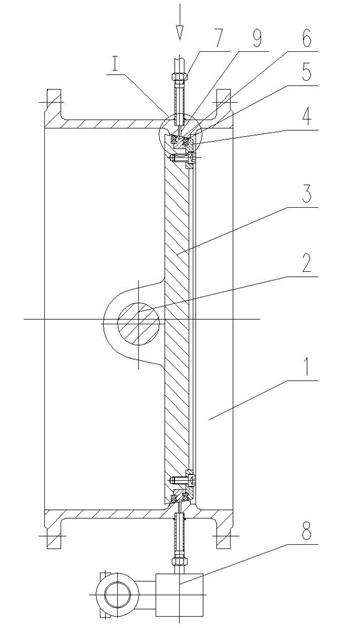

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the double-sealed butterfly valve described in Embodiments 1 and 2 of the present invention includes a valve body 1, a valve stem 2, a butterfly plate 3, a pressure plate 4, and a sealing ring 5, wherein two sealing rings 5 are respectively on both sides of the support ring 6, through The pressure plate 4 is fixed on the butterfly plate 3, and the two sealing rings 5 form an annular sealing cavity with the valve seat of the valve body 1, and a channel 9 is set on the valve seat of the valve body 1 corresponding to the position of the sealing cavity, and the channel 9 is connected with the valve body The connecting pipe 7 on 1 is connected, and the number of connecting pipes 7 is two. One of the connecting pipes 7 is connected to a device with a certain pressure of water or nitrogen, and the other connecting pipe 7 is connected to the pressure transmitter 8. The pressure transmitter 8 The pressure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com