Method for manufacturing and fixing submarine pipeline buckle arrestor on basis of morphological energy adsorption

A technology of submarine pipeline and fixing method, which is applied in the production and fixing of buckling propagation, and achieves the effects of significant economic value, increased crossing pressure, and guaranteed safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

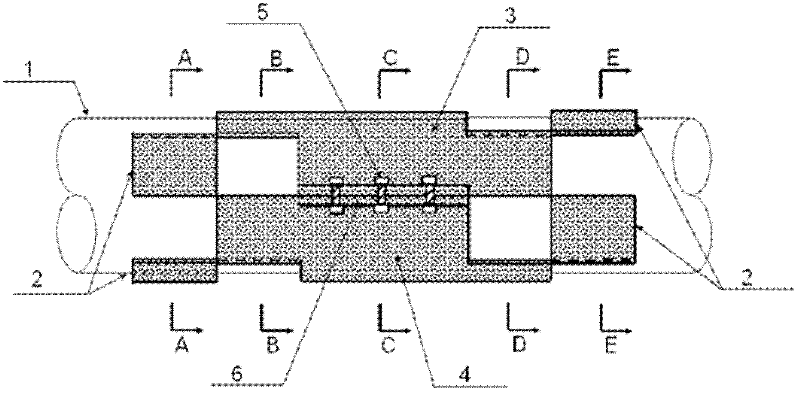

[0037] Such as figure 1As shown, the present invention includes an assembly structure composed of a pair of upper and lower valve shells and 6 interference shells. The shell plate material should be API 5L X65 type or higher grade X70, X80 grade steel of the same material as the deepwater submarine pipeline. Its main function is to prevent buckling propagation of submarine pipelines under complex environments and loads, and ensure the safety of the entire pipeline.

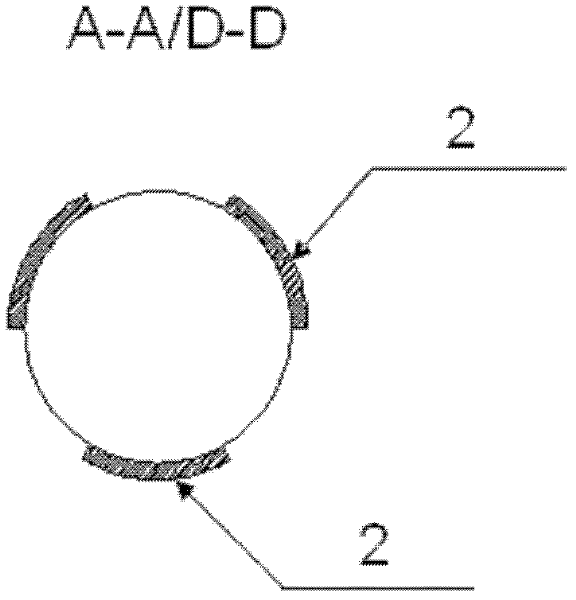

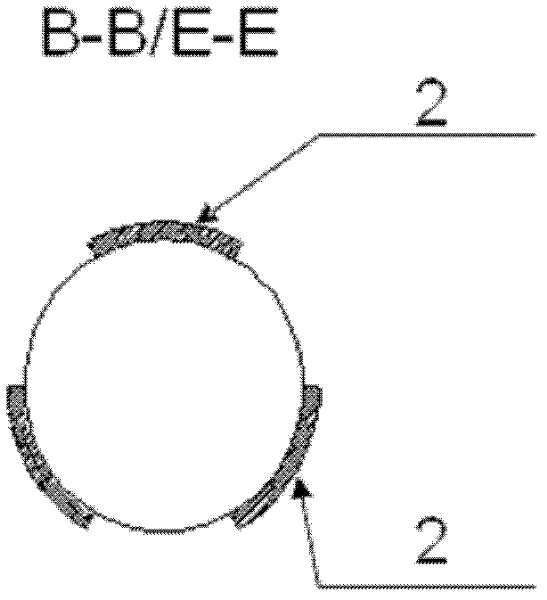

[0038] Interference shells are distributed on both sides of the anti-bending device along the pipe length direction on the pipe length of about 1 to 1.5 times the pipe diameter, and the wall thickness of the interference shell is 2 to 4 times the pipe wall thickness. There are 3 interference shells on each side, and the arc of each interference shell is 60 degrees, and they are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com