Riveting device of relay contact and riveting method thereof

A relay contact and riveting device technology, applied in relays, circuits, electrical components, etc., can solve the problems of high material cost and manufacturing cost, crushed by riveted contacts, low riveting quality and work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

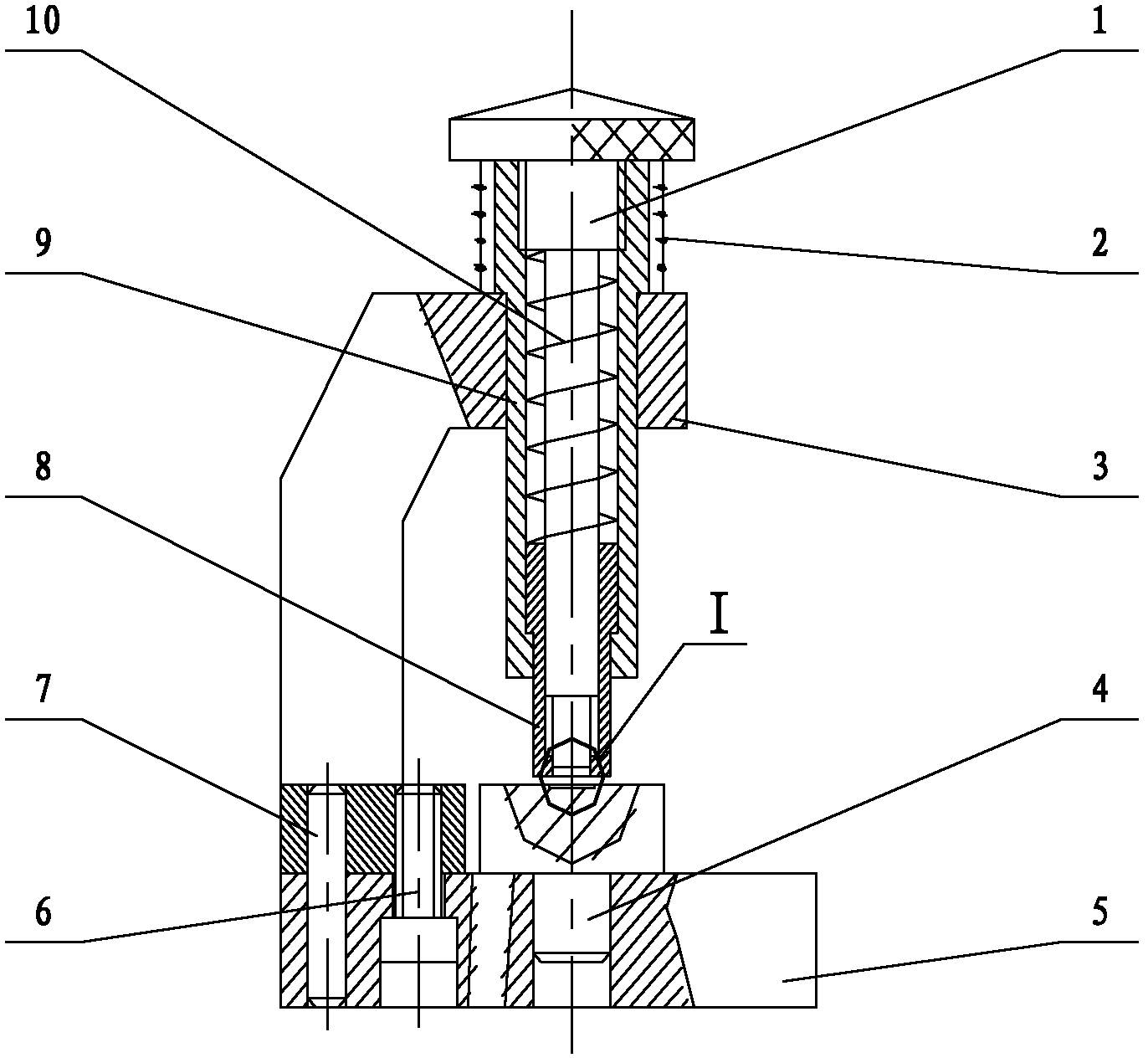

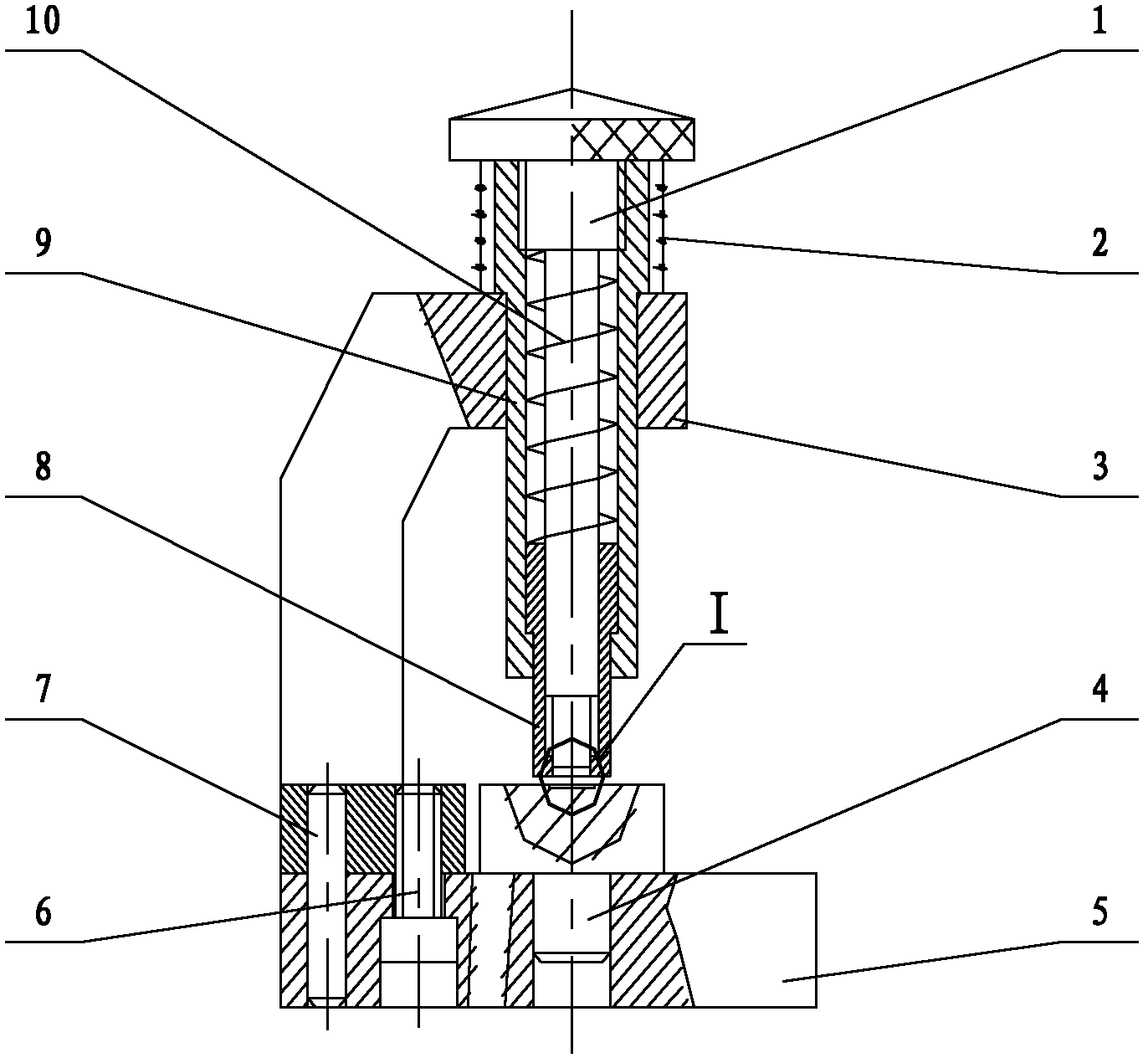

[0013] The present invention is described in further detail in conjunction with accompanying drawing:

[0014] The present invention is a relay contact riveting device, which mainly consists of a punch 1, a compression spring 2, a support arm 3, a socket pin 4, a base 5, a screw 6, a cylindrical pin 7, a pressure sleeve 8, a guide sleeve 9 and a compression spring 10 composition.

[0015] A relay contact riveting device according to the present invention. The punch 1 is composed of a punch main body 1-1 and a hard alloy riveting head 1-2. The socket pin 4 is composed of a socket pin main body 4-1 and a hard alloy bottom socket 4. -2 composition.

[0016] In the relay contact riveting device described in the present invention, the punch 1 and socket pin 4 of the working part are inlaid with materials with high strength and good wear resistance, which increases the service life from 20,000 times of traditional materials to 300,000 times. The service life has been increased by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com