Water cooling device for oxygen lance of bottom blowing lead smelting furnace

A technology of water cooling device and lead smelting furnace, which is applied in the field of water cooling device of the oxygen lance of the bottom blowing lead smelting furnace, can solve the problems affecting the smooth production, short service life of the oxygen lance, high replacement rate of the oxygen lance, etc. The effect of long service life and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

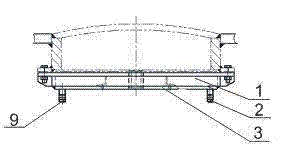

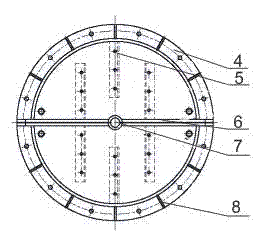

[0016] A water cooling device for an oxygen lance of a bottom blowing lead smelting furnace, comprising two semi-cylindrical water jackets with a cavity structure composed of a bottom plate 4, an arc-shaped web 1, a vertical plate 6 and a top plate 3, and the bottom plate of the water jacket The diameter of 4 is greater than the diameter of the top plate 3, and the center of the vertical plate 6 of the two semi-cylindrical water jackets is recessed to the inner cavity of the water jacket to form an arc-shaped gap, and the two water jackets are butted to form a complete cylinder. Two arc-shaped gaps form a full-circle oxygen lance hole 7 for the oxygen lance to pass through; the top plate 3 of the two water jackets is provided with a water inlet pipe 2 and an outlet pipe 9 communicating with the inner cavity of the water jacket; Several partitions 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com