Large-volume concrete pouring method for nuclear island raft foundation

A large-volume concrete and concrete technology, applied in the direction of construction, infrastructure engineering, etc., can solve problems such as low efficiency, long construction period, and unsatisfactory, and achieve the effect of improving work efficiency and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0019] A kind of nuclear island raft foundation mass concrete pouring method described in this embodiment, its steps are:

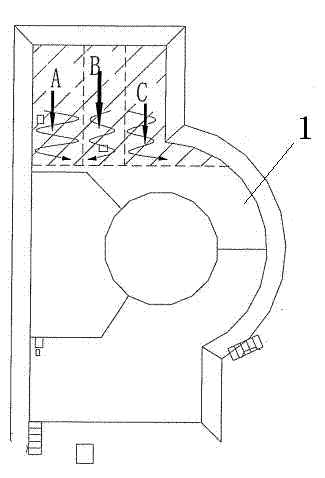

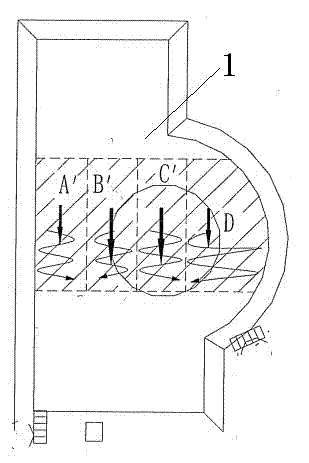

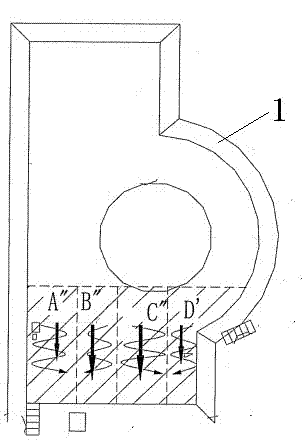

[0020] Step 1. After setting up the formwork, if Figure 1 to Figure 3 As shown, in the horizontal direction, the nuclear island raft foundation area 1 to be poured is divided into three sub-areas, and then, as Figure 4 As shown, in the longitudinal direction, each sub-region is divided into four pouring layers, and the layer thickness is determined according to the length of the vibrator and the supply of concrete. In this embodiment, the thickness of each layer is about 18 inches. Then in the horizontal direction, divide each pouring layer into multiple pouring sections on average;

[0021] Step 2. When pouring, the No. 1 automobile pump, the No. 2 automobile pump, the No. 3 automobile pump and a distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com