Suspension hardware fitting for optical phase conductor

An optical fiber composite, phase line technology, applied in the direction of the cable suspension device, etc., can solve the problems of fiber unit deformation, fiber quality damage, short clip body, etc., to achieve good stress distribution, improve the ability to withstand stress, and not easily damaged. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

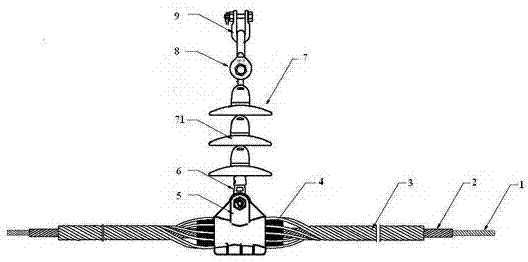

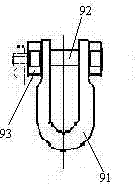

[0029] like figure 1 As shown, the suspension fittings used for optical fiber composite overhead phase line 1 include inner twisted wire 2, outer twisted wire 3, rubber clamp block 4, cast aluminum shell 5, bowl hanging plate 6, insulator string 7, ball hanging ring 8 and U-shaped hanging ring 9.

[0030] Among them, the inner twisted wire 2 and the outer twisted wire 3 form a double-layer pre-twisted wire structure. Both ends of the structure have an additional pre-twisted length. The skein 3 is coated on the pre-twisted inner skein 2; the rubber clamp 4 is located at the midpoint of the lengths of the inner skein 2 and the outer skein 3, and the rubber clamp 4 is arranged outside the inner skein 2 and connected to the outer skein Inside the wire 3, that is, the rubber clamp block 4 is sandwiched between the inner twisted wire 2 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com