Product pin cutting machine special for pin inserting machine

A cutting machine and product technology, applied in the field of product cutting machine, can solve the problems that the processing efficiency and precision cannot be guaranteed, and achieve the effects of improving work efficiency and quality, reducing manpower input, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

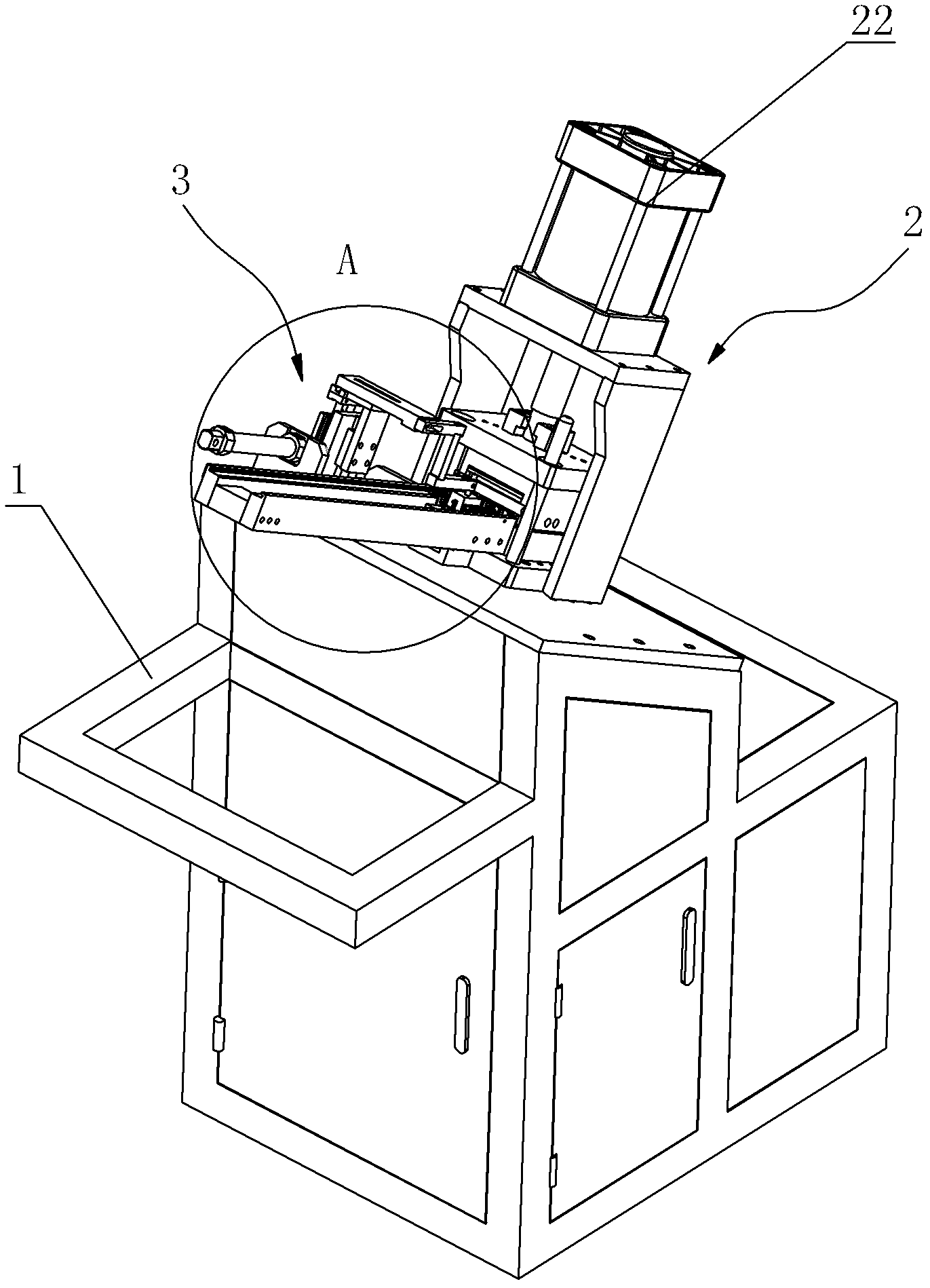

[0021] Such as figure 1 A product-cutting machine dedicated to a PIN inserting machine shown includes a frame 1, a punching mechanism 2 arranged on the frame 1, and a feeding mechanism 3, wherein:

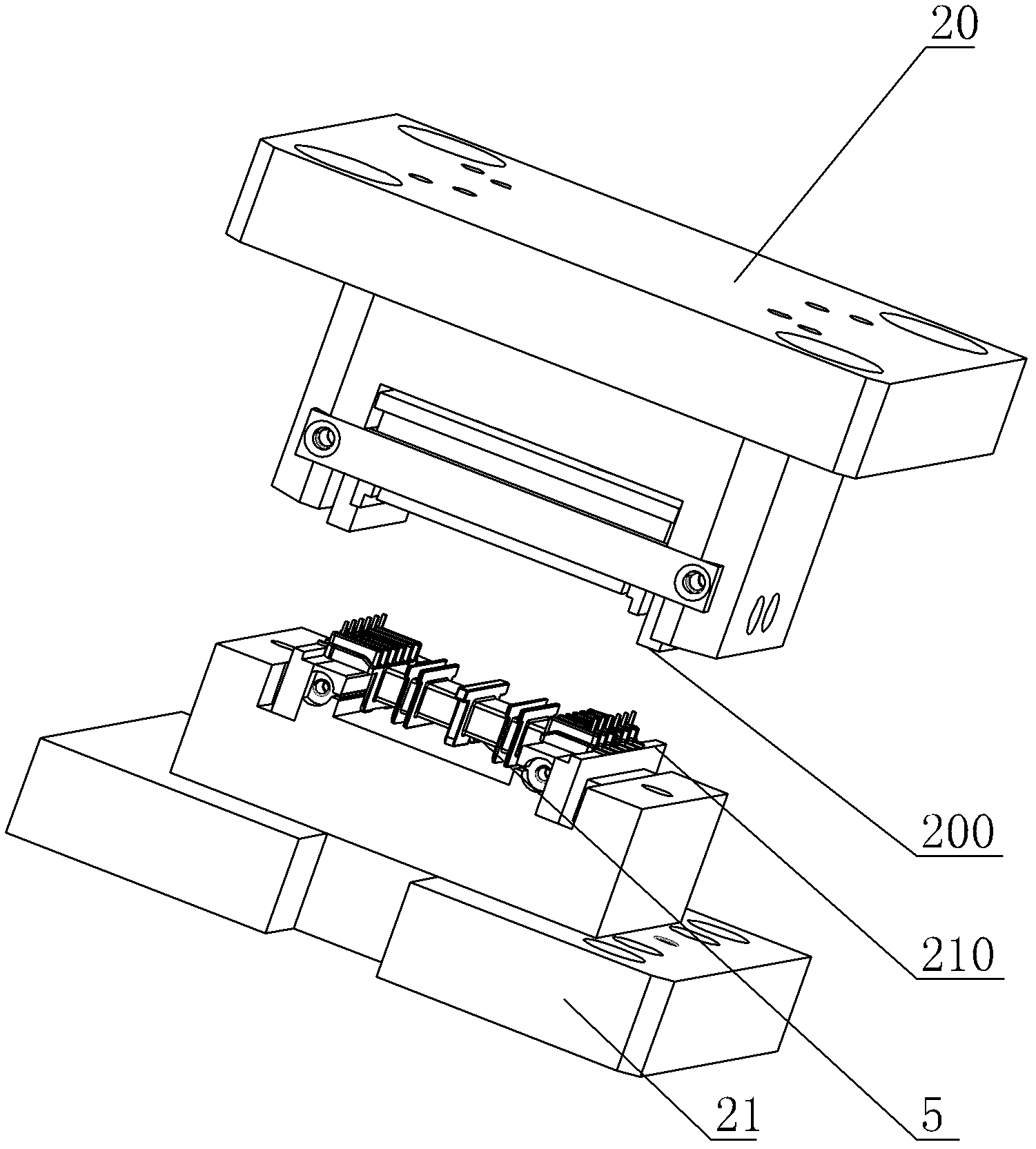

[0022] Such as figure 2 As shown: the punching mechanism 2 includes an upper knife seat 20 , a lower knife seat 21 and a punching drive mechanism connected to the upper knife seat 20 in transmission. The upper knife seat 20 is provided with an upper knife edge 200, and the lower knife seat 21 is provided with a lower knife edge 210. The upper knife edge 200 and the lower knife edge 210 are arranged tangentially, and the upper knife edge 200 is arranged on the outside of the lower knife edge 210. In this embodiment , the punching drive mechanism selects the punching oil cylinder 22;

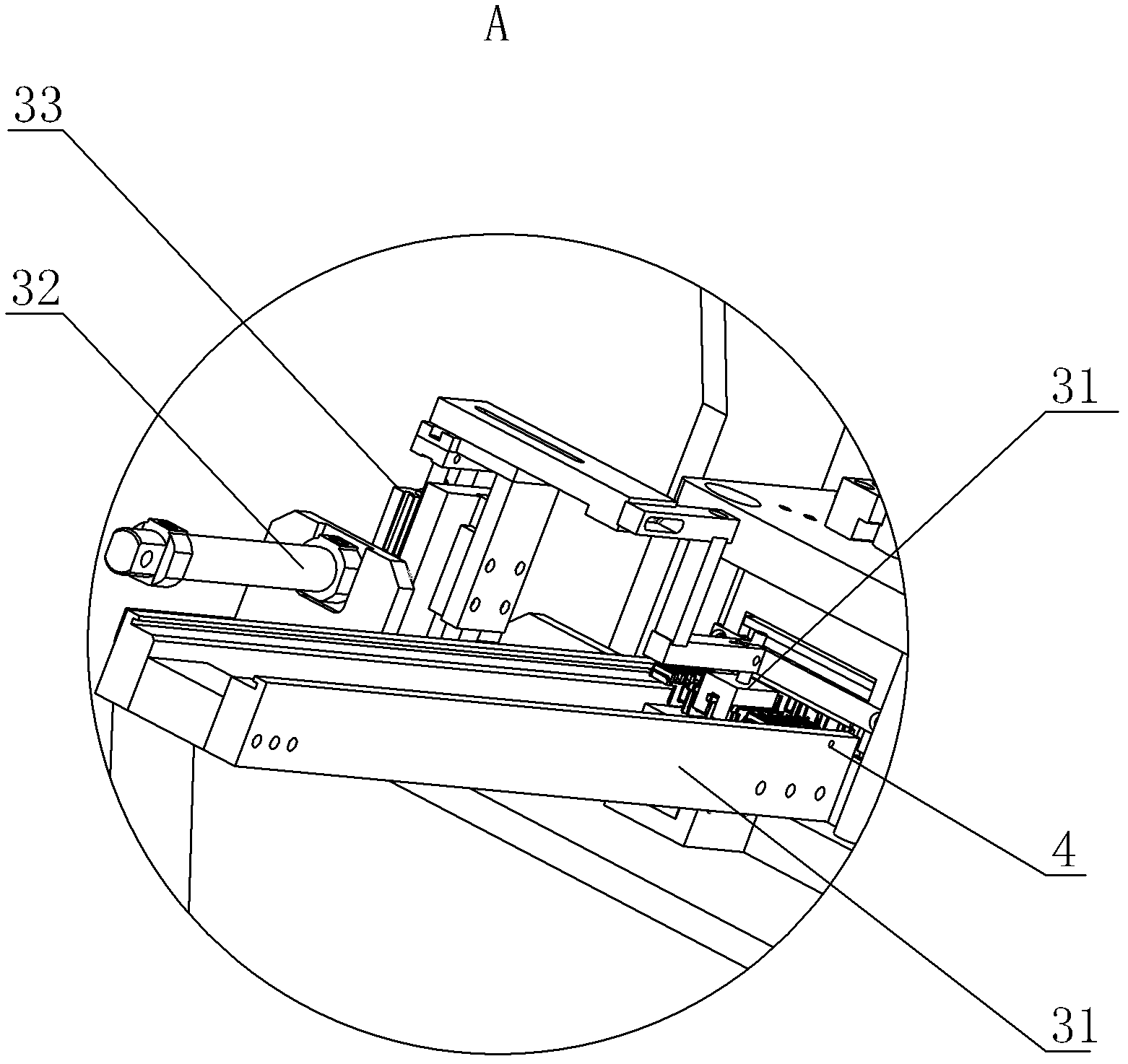

[0023] Such as image 3 As shown: the feeding mechanism 3 includes a conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com