Motion mechanism for underwater welding robot

A technology of underwater welding and motion mechanism, which is applied in the direction of welding equipment, electrode characteristics, arc welding equipment, etc., and can solve the problems of difficult flexibility and accuracy of the hydraulic mechanism, and the inability to complete automatic tracking welding of the weld seam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in more detail below in conjunction with the accompanying drawings.

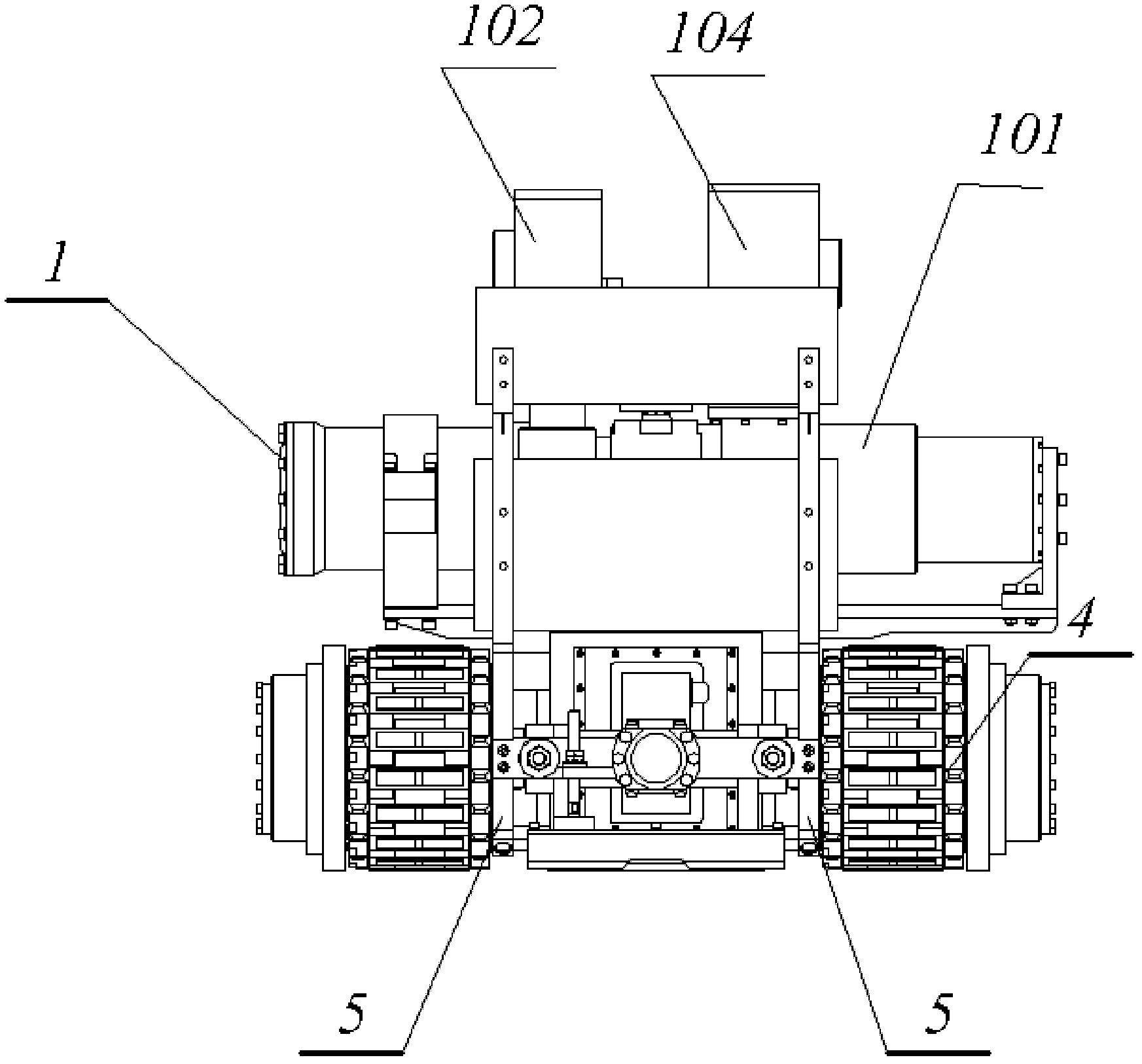

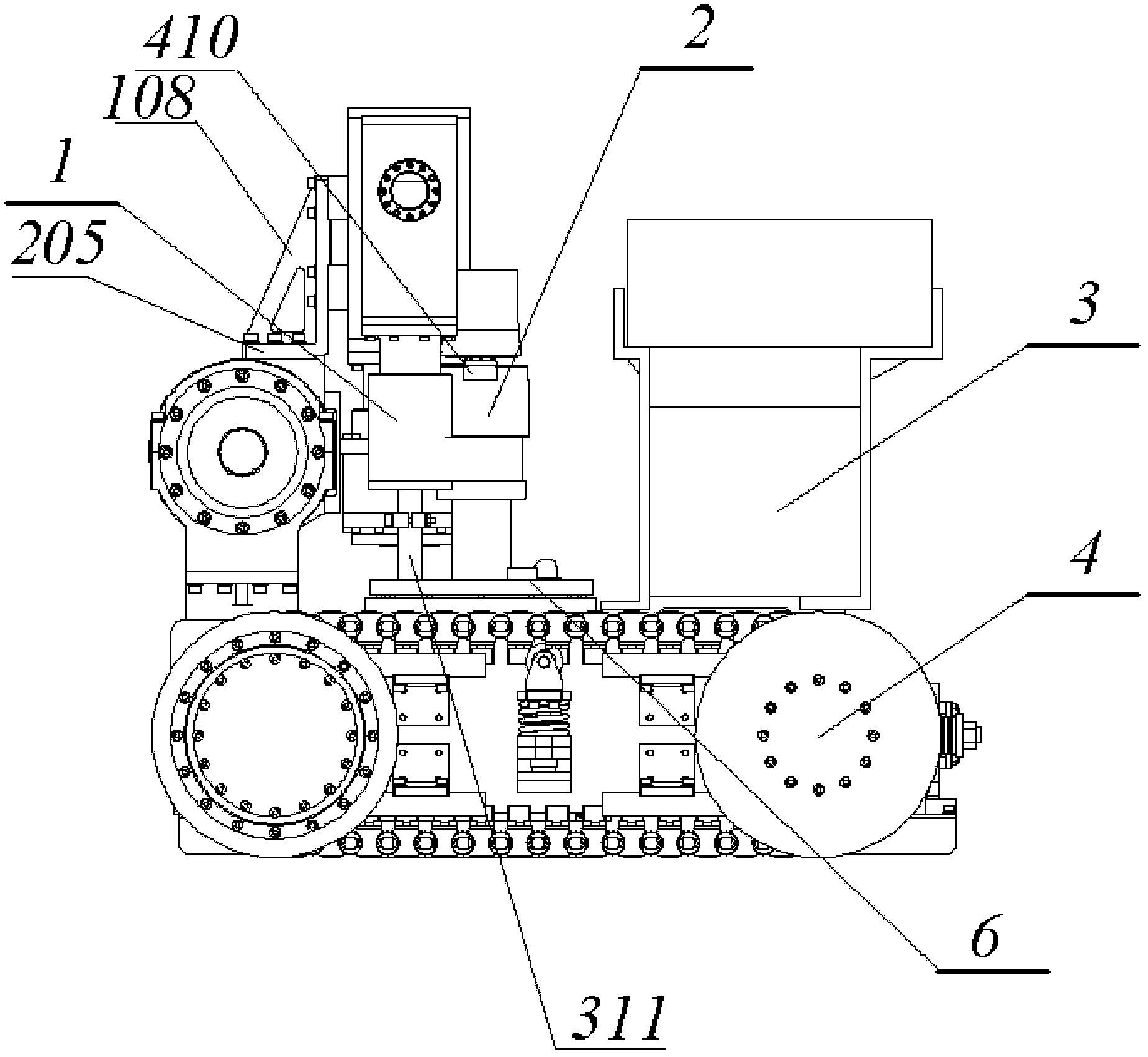

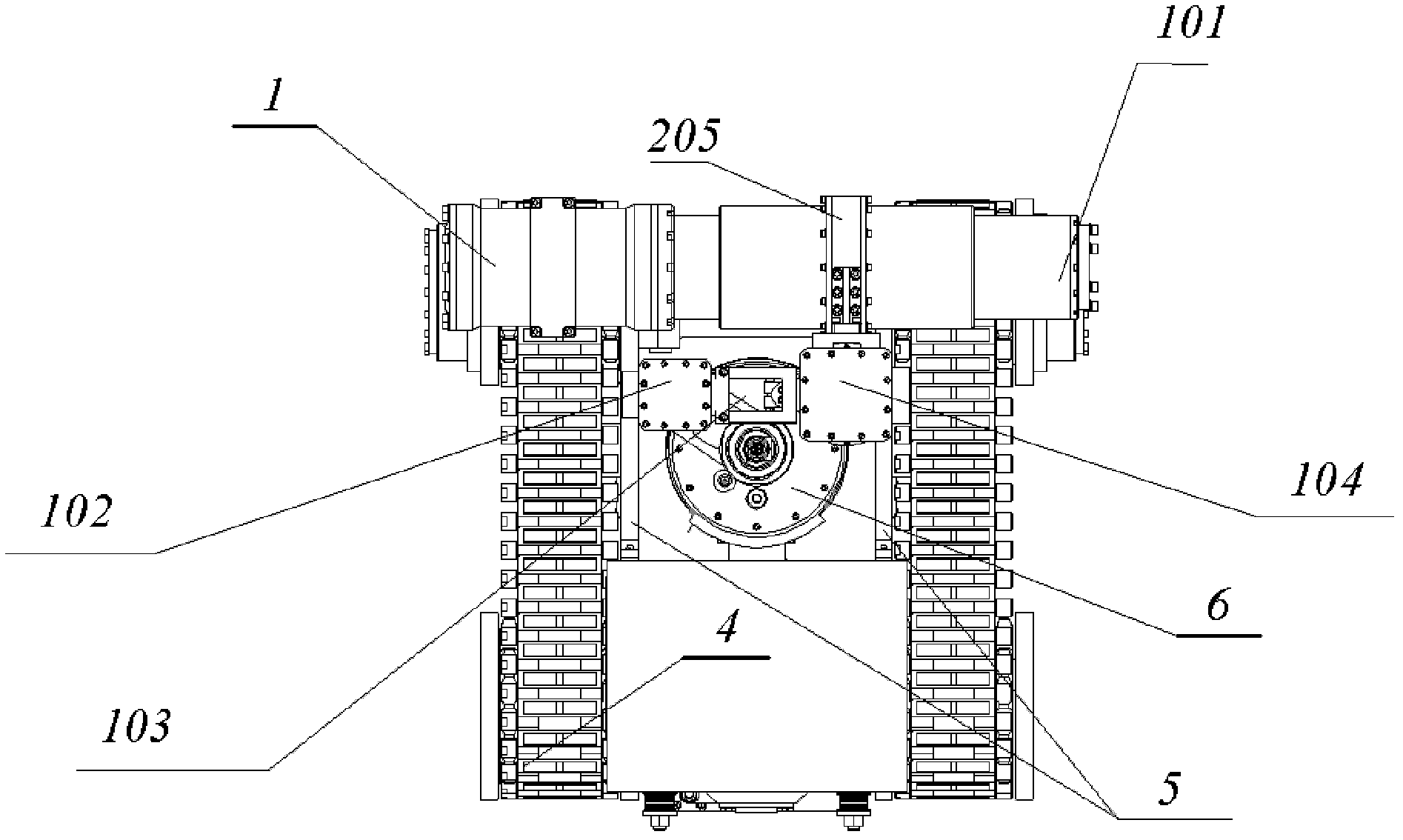

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 As shown, the kinematic mechanism 1 of the underwater welding robot includes a lateral kinematic mechanism 101 with a lateral kinematic mechanism slider 205, and the lateral kinematic mechanism slider 205 is connected to a right-angled side of a right-angled triangle bracket 108, and the right-angled triangle bracket 108 The other right-angled side and the partial cover pressing mechanism 104 are connected in the vertical direction, and the movable block of the partial cover pressing mechanism 104 is connected with the partial cover 6 of the underwater welding robot through the partial cover connecting rod 311, and the partial cover is pressed in addition. The mechanism 104 is connected with the welding torch adjustment mechanism 102 through the connecting frame 103, the partial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com