Vacuum chuck de-molding device for concrete tubular pile

A technology of concrete pipe piles and vacuum suction cups, which is applied to ceramic molding machines and manufacturing tools, can solve problems such as potential safety hazards, easy shaking of steel wire ropes, and scratches on concrete pipe piles, achieving high safety, high demoulding efficiency, and labor low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

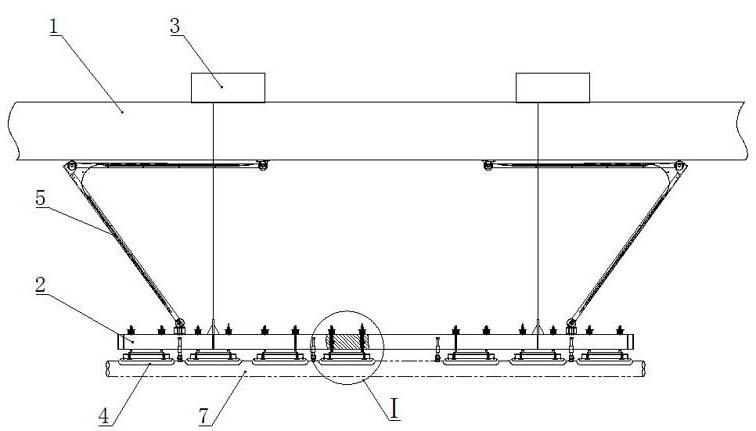

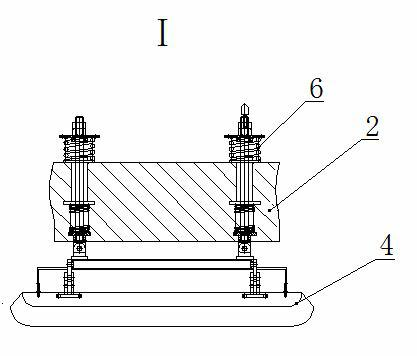

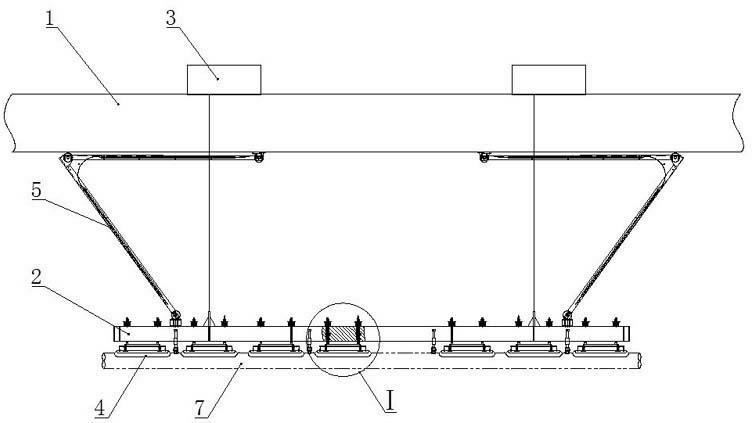

[0012] Such as figure 1 , 2 As shown, it includes a beam 1, a movable spreader 2, a crane trolley 3, a vacuum suction cup 4, a folding arm 5, and a shock-absorbing spring 6.

[0013] A movable sling 2 is provided under the beam 1 of the above-mentioned traveling crane, and the movable sling 2 is connected to the hoisting trolley 3 on the beam 1 by a wire rope.

[0014] A number of vacuum suction cups 4 connected to the vacuum system are distributed on the movable spreader 2, and vacuum suction holes are evenly distributed on the lower end surface of the vacuum suction cup 4. A shock-absorbing spring 6 is arranged between the movable spreader 2 and the vacuum suction cup 4.

[0015] An anti-sway mechanism is provided between the movable sling 2 and the cross beam 1, and the anti-sway mechanism includes a folding arm 5 whose upper and lower ends are hinged to the cross beam 1 and the movable sling 2 respectively. The folding plane of the folding arm 5 is perpendicular to the translati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com