Auxiliary sizing device for plastic pipe production

A production auxiliary and plastic pipe technology, which is applied in the field of plastic pipe production, can solve the problems of slow production speed, high cost, and low work efficiency, and achieve the effects of increased production speed, low cost, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

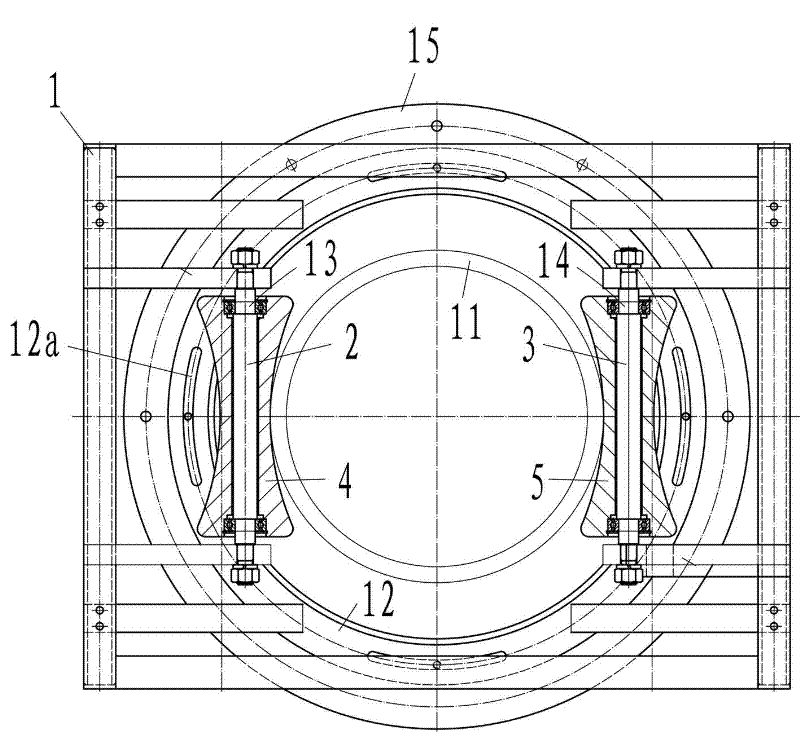

[0041] Embodiment 1, see attached figure 1 , plastic pipe production auxiliary shaping device, including a frame 1, the frame 1 is a whole in this embodiment, welded by steel pipes, the frame 1 is fixed on the swivel seat 12, and a plurality of mounting holes 12a are evenly distributed on the swivel seat 12, At the same time, the rotating seat 12 is fixed on the base plate 15, and is connected with the cooling water tank and the vacuum calibrating box through the base plate 15, from which figure 1 It can be seen from the figure that there are four mounting holes 12a in this embodiment, which are long slotted holes for easy adjustment. The left roller 4 and the right roller are rotatably installed on the frame 1 through the left shaft 2 and the right shaft 3. 5. The left shaft 2 and the left roller 4, the right shaft 3 and the right roller 5 can be integrally formed, or can be assembled separately. The left roller 4 and the right roller 5 are made of nylon or other wear-resis...

Embodiment 2

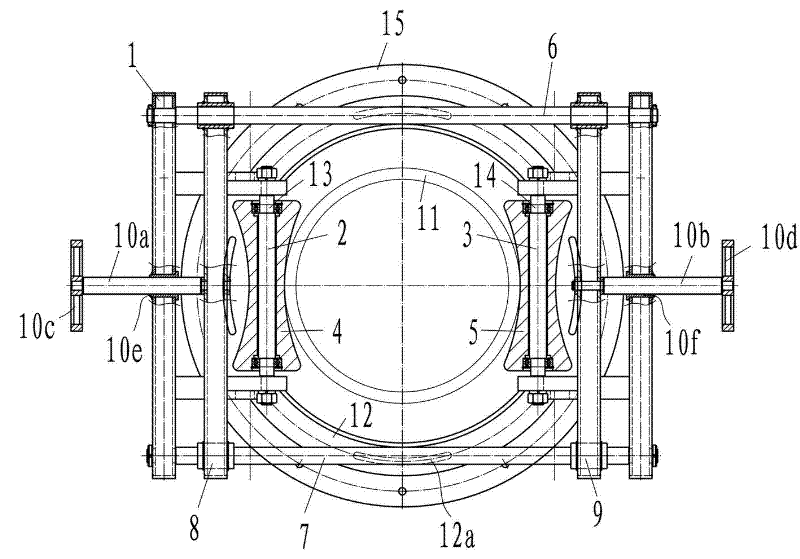

[0042] Embodiment 2, see attached figure 2 , 3 , the disadvantage of embodiment 1 is that after the left roller 4 and the right roller 5 are installed, it is not easy to adjust, and an auxiliary shaping device can only be suitable for plastic pipes of one specification. There are an upper linear guide rail 6 and a lower linear guide rail 7. The upper linear guide rail 6 and the lower linear guide rail 7 can use purchased standard parts. Of course, the price is relatively expensive, and the structure in this embodiment can also be used. In this embodiment, two The round tube is used as the guide rail of the upper linear guide rail 6 and the lower linear guide rail 7, and four linear bearings are used as the sliders of the upper linear guide rail 6 and the lower linear guide rail 7. The structure is very simple, the price is very cheap, and the performance can meet the needs. The sliders of the upper linear guide rail 6 and the lower linear guide rail 7 are fixed with a left m...

Embodiment 3

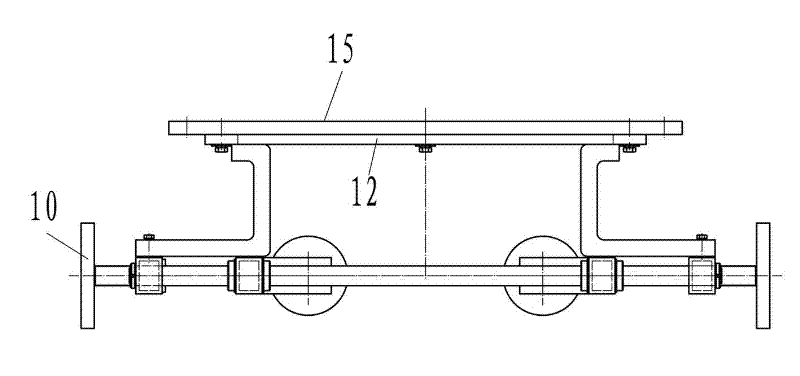

[0043] Embodiment 3, see attached Figure 4, although embodiment 2 can be applied to plastic pipes with different diameters, it needs to rotate the left and right handwheels separately for adjustment, which is slow and cumbersome to adjust, takes a long time to adjust, and is not necessarily synchronized. In order to solve this problem, this implementation The propulsion device 10 in the mode includes a screw rod 10g, on which there are left external threads 10g1 and right external threads 10g2 in opposite directions on the screw rod 10g, and the left external threads 10g1, right external threads 10g2 and the left moving member 8 , the right moving part 9 is screwed, and the left moving part 8 and the right moving part 9 can be provided with internal screw holes or mounting screw sleeves to cooperate with the left external thread 10g1 and the right external thread 10g2, and a hand wheel 10h is fixed at the end of the screw rod 10g , through the hand wheel 10h to drive the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com