Optical glass, preformed blank and optical element

A technology of optical glass and optical components, which is applied in the field of preforms, optical components and optical glass, and can solve problems such as aberration in the residual blue area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

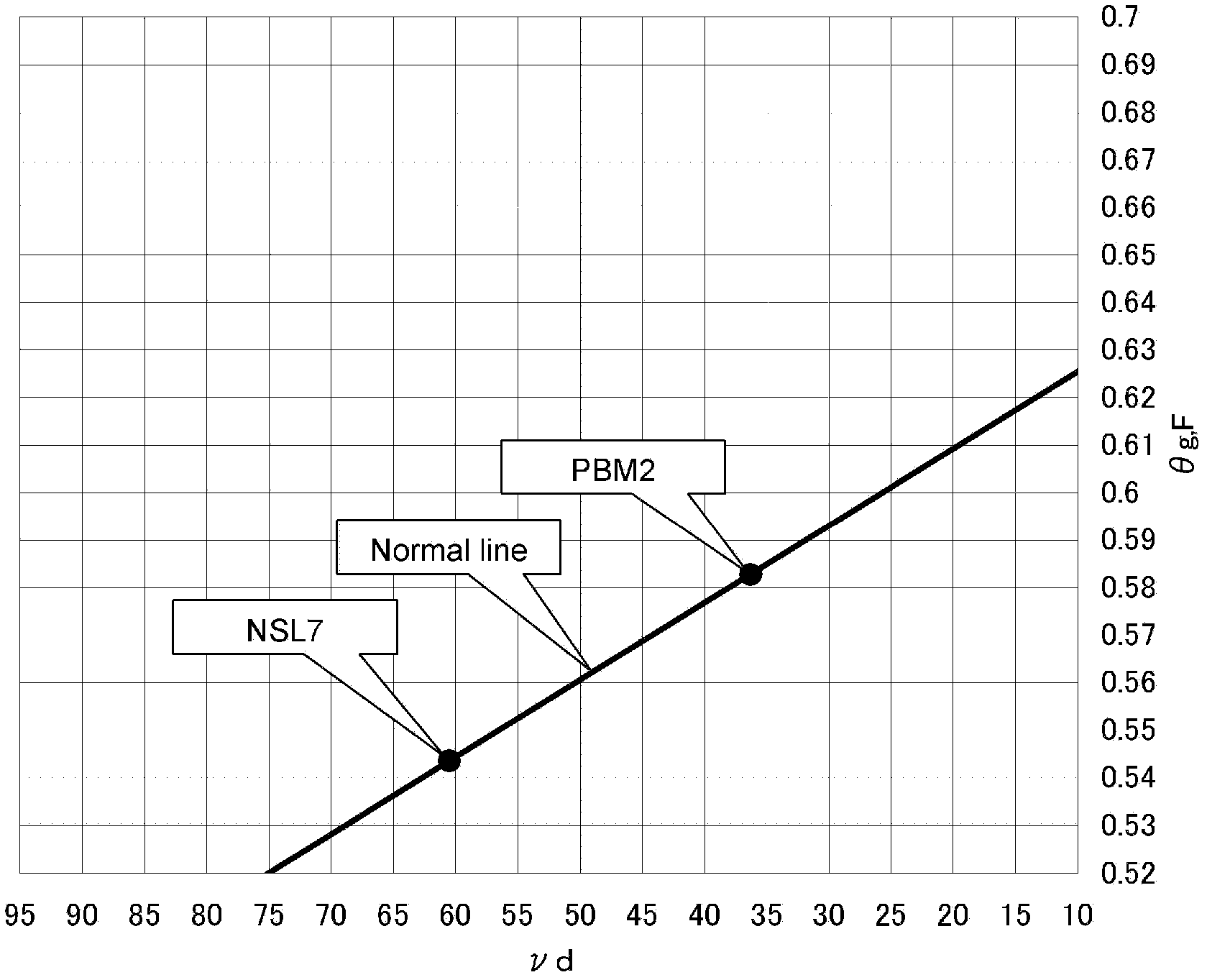

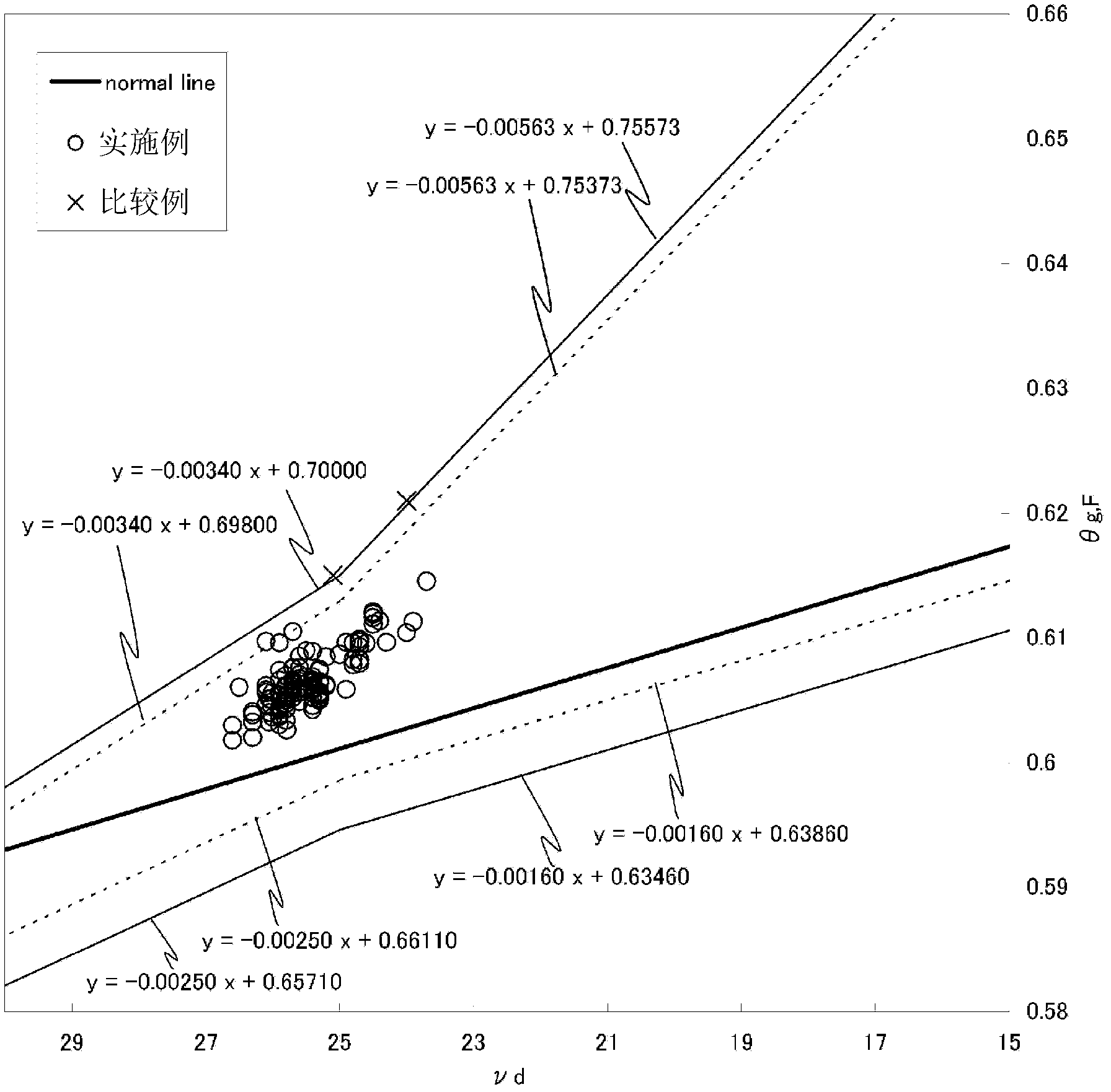

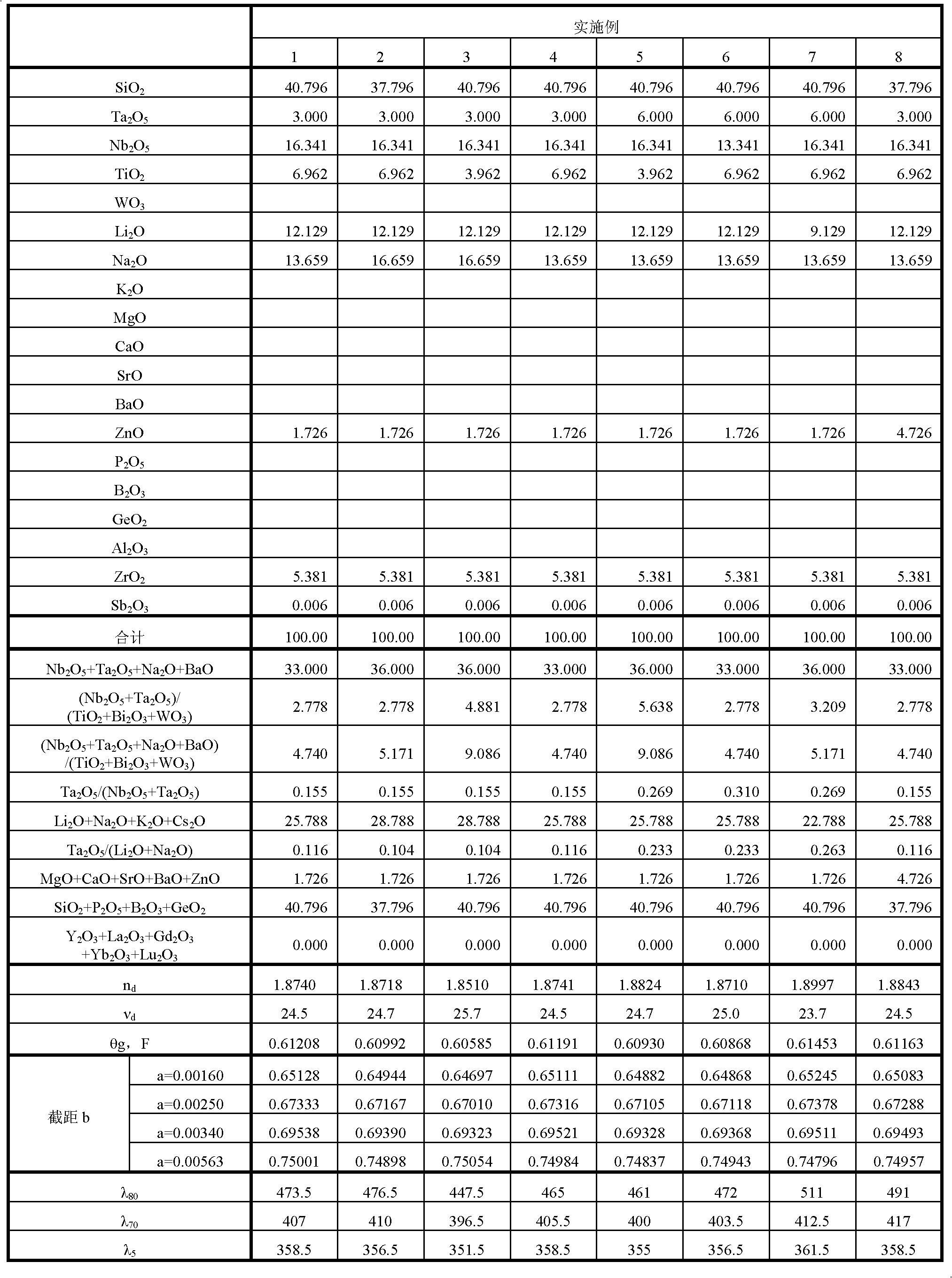

[0077] The optical glass of the present invention contains SiO 2 Ingredients and from Ta 2 o 5 Composition, Nb 2 o 5 Composition, Na 2 With one or more components selected from the group consisting of O component and BaO component, the partial dispersion ratio (θg, F) and Abbe number (v d ), between v d Satisfy within the range of ≤25 (-0.00160×v d +0.63460)≤(θg, F)≤(-0.00563×v d +0.75573), at v d Satisfied in the range of >25 (-0.00250×v d +0.65710)≤(θg, F)≤(-0.00340×v d +0.70000) relationship. In particular, it is preferable to contain SiO in an amount of 60.0% or less in mole percent relative to the total amount of the glass in terms of an oxide composition. 2 Composition and less than 25.0% Ta 2 o 5 Element. By using SiO 2 Ingredients and from Ta 2 o 5 Composition, Nb 2 o 5 Composition, Na 2 One or more components selected from the group consisting of O component and BaO component, and setting these contents within the specified range can make the gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com