Top-entry floating ball valve

A floating ball valve and top loading technology, which is applied to valve devices, engine components, cocks including cutting devices, etc., can solve the problems of many sealing surfaces, difficult assembly, easy cracking, etc., and achieve less sealing positions, convenient processing, and favorable assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

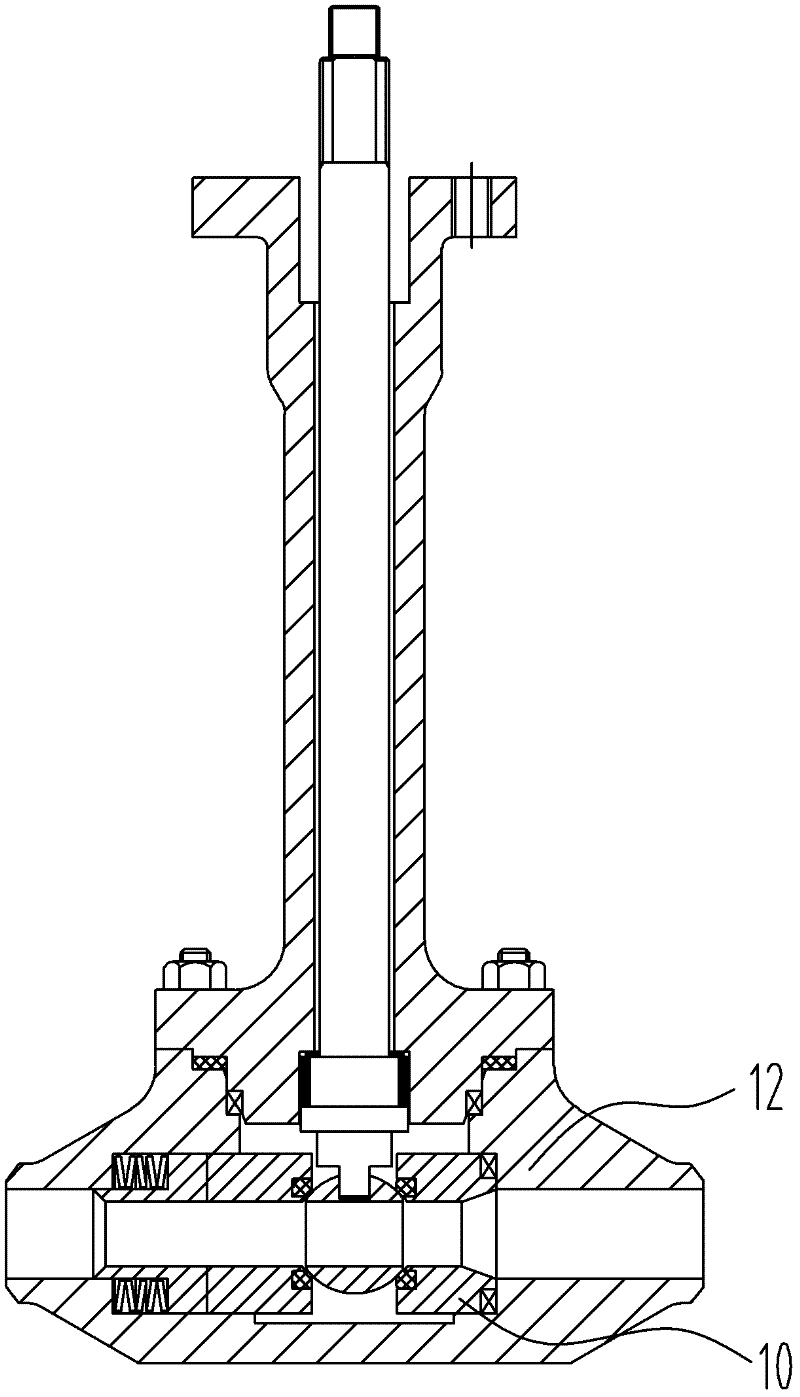

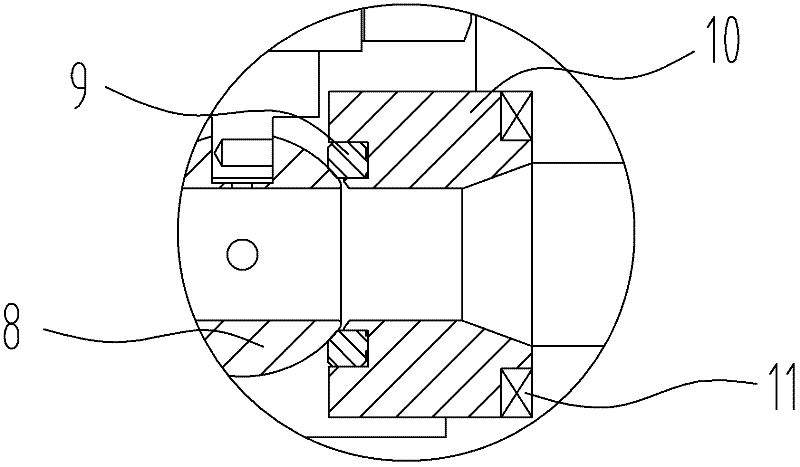

[0037] Embodiment one: see Figure 4 and Figure 5 As shown, a top-entry floating ball valve includes a valve body 1, a valve seat 2 at the outlet end, a ball 3, a valve cover, and a valve stem assembly. The valve stem assembly is inserted into the valve cover, and its lower end is inserted into the ball 3, the valve cover is fixedly connected to the top of the valve body 1 to form a top entry floating ball valve structure. Through the above structure, when the floating ball valve fails on the pipeline and needs to be repaired, it is not necessary to dismantle the valve from the pipeline, only the flange bolts and nuts fixedly connecting the bonnet and the valve body need to be removed, and the bonnet and stem assembly together Remove from the valve body, then remove the ball and seat, the ball and seat can be repaired online.

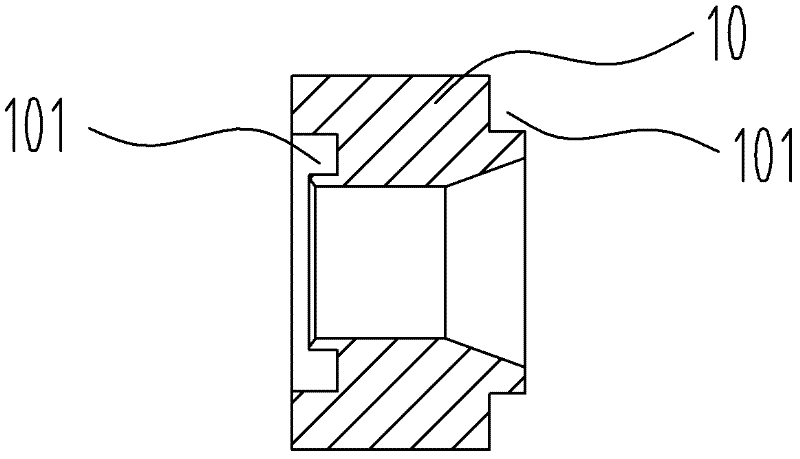

[0038] The outlet valve seat 2 is composed of an inner valve seat 20 and an outer valve seat 21. The inner valve seat 20 is provided with a sealing ...

Embodiment 2

[0044] Embodiment two: see Figure 7 As shown, the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that the composite surface of the inner valve seat 20 and the outer valve seat 21 is a step surface, and through the above structure, the composite surface of the inner and outer valve seats is realized. sealing requirements.

[0045] No annular groove is formed on the outer side wall of the outer valve seat 21 that is in contact with the valve body 1 .

Embodiment 3

[0046] Embodiment three: see Figure 8 As mentioned above, the structure of the third embodiment is basically the same as that of the first embodiment, except that the inner diameter of the inlet end of the floating ball valve is equal to the inner diameter of the outlet end, so the inner hole of the inner valve seat 20 is a cylindrical hole.

[0047] The inner valve seat and outer valve seat of the present invention are not limited to the three structures described in the above embodiments, but any inner valve seat and outer valve seat structure that those skilled in the art can think of, and the two are combined into an outlet port The invention of the valve seat all falls within the protection scope of the present invention.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap