Tertiary air hose elbow of cement kiln

A technology for pipe elbows and cement kilns, which is applied in the direction of elbows, pipes/pipe joints/fittings, siphons, etc., can solve the problems of wear-resistant castables that are easy to fall off, life, decline, etc., and achieve the purpose of improving and ensuring performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

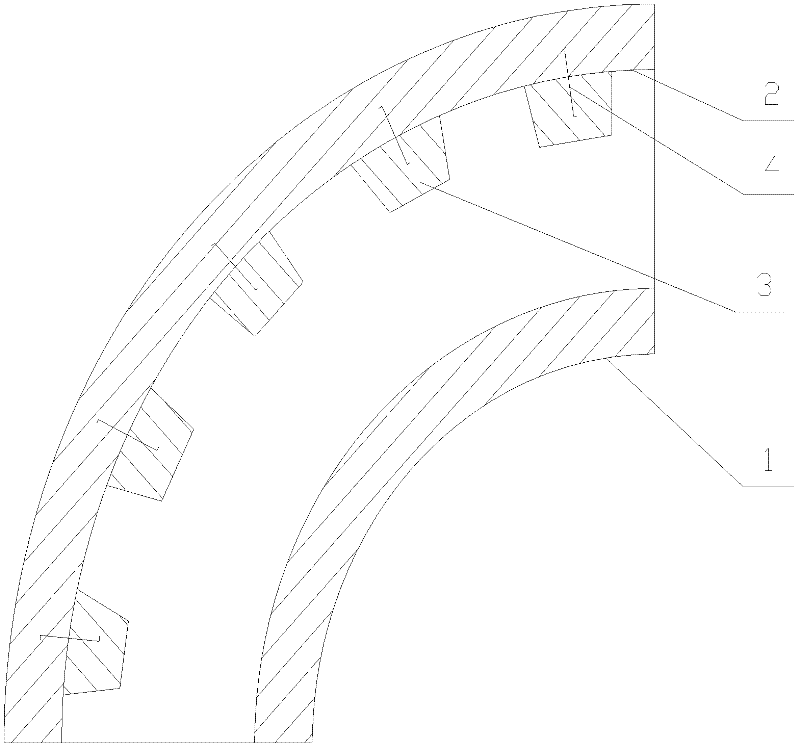

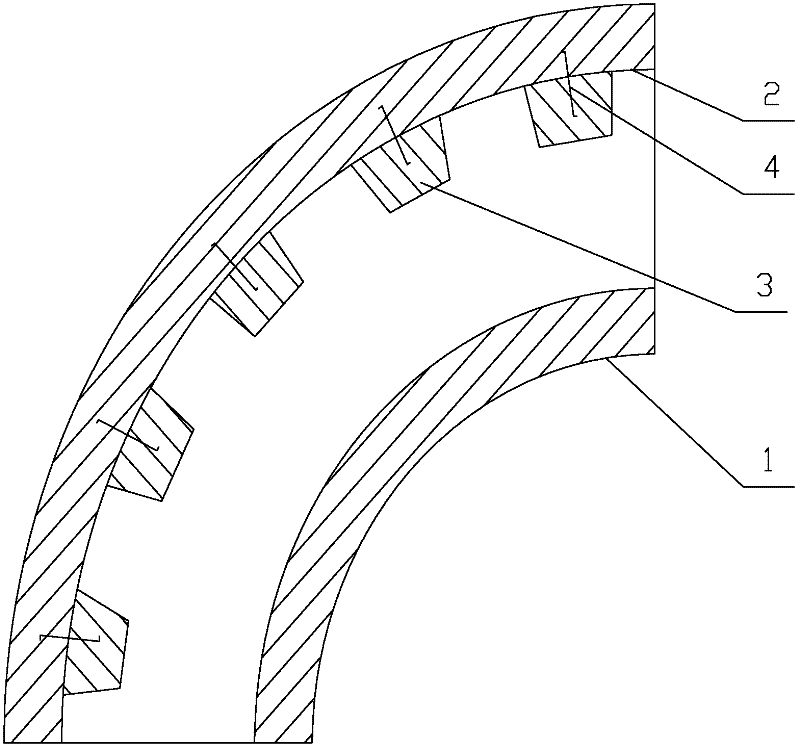

[0011] Such as figure 1 As shown, a cement kiln tertiary air pipe elbow includes an outer wall 1 and an inner wall 2, the outer wall 1 and the inner wall 2 are arc-shaped, and at least one bump 3 is provided on the inner wall 2, and the bump 3 3 is a trapezoidal shape, and can also be other square, arc-shaped and other shapes that are easy to process. The effect of the trapezoidal shape is better. The bumps 3 are evenly distributed on the inner wall 2, so that the bumps 3 can evenly withstand the effect of hot air flow , which better protects the service life of the inner wall 2 of the elbow. The metal anchor 4 is arranged in the bump 3. One end of the metal anchor 4 is placed in the bump 3, and the other end is connected to the inner wall 2. It can also be Fixing by other means, using metal anchors for fixing facilitates the disassembly and replacement of the bump 3, which is convenient to use and simple in structure.

[0012] Evenly open installation holes on the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com