Drive device for driving work unit

A driving device and work unit technology, applied in applications, home appliances, kitchen appliances, etc., can solve the problems of increased storage space and large devices, and achieve the goal of reducing storage space, reducing production costs, and improving application possibilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

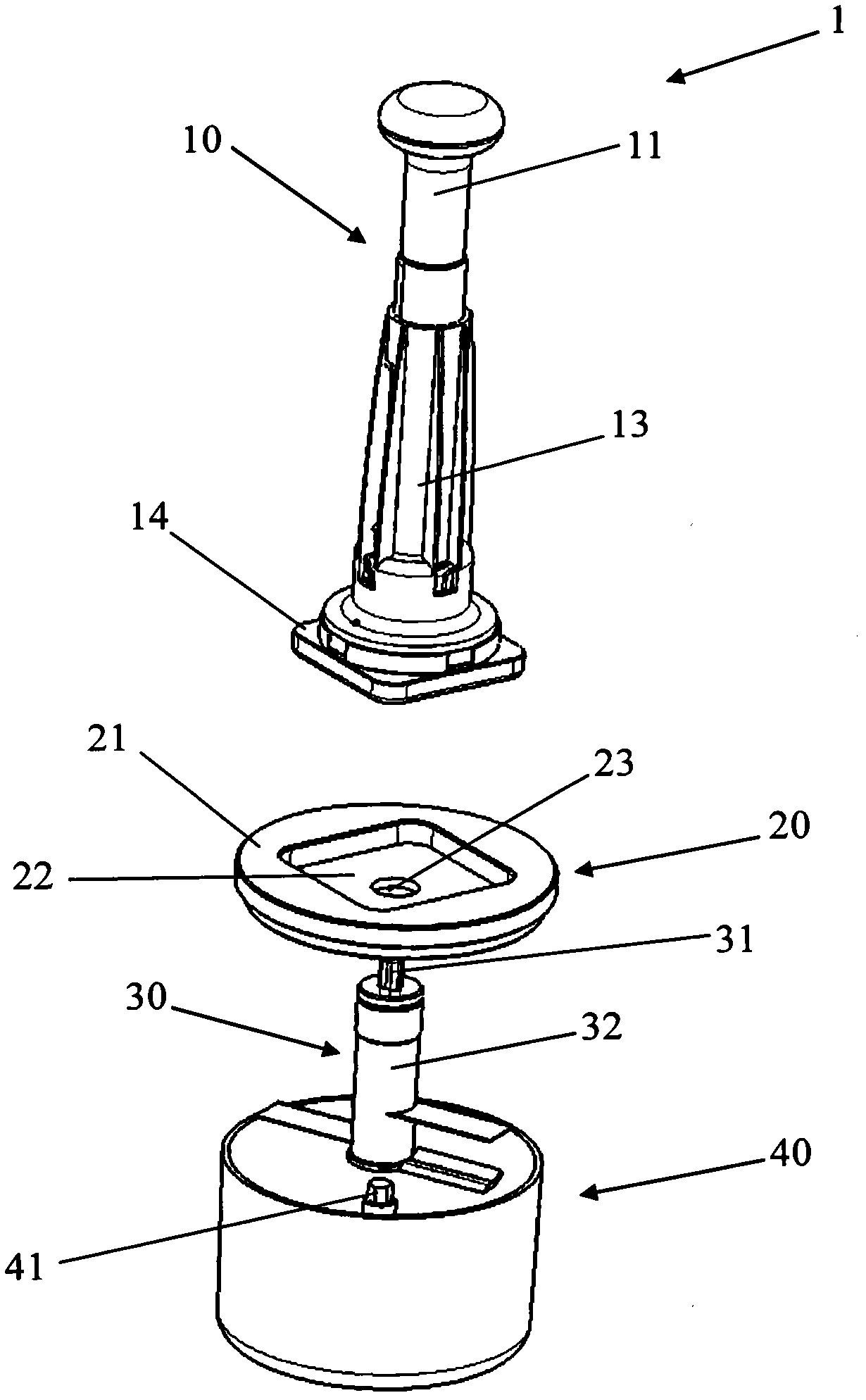

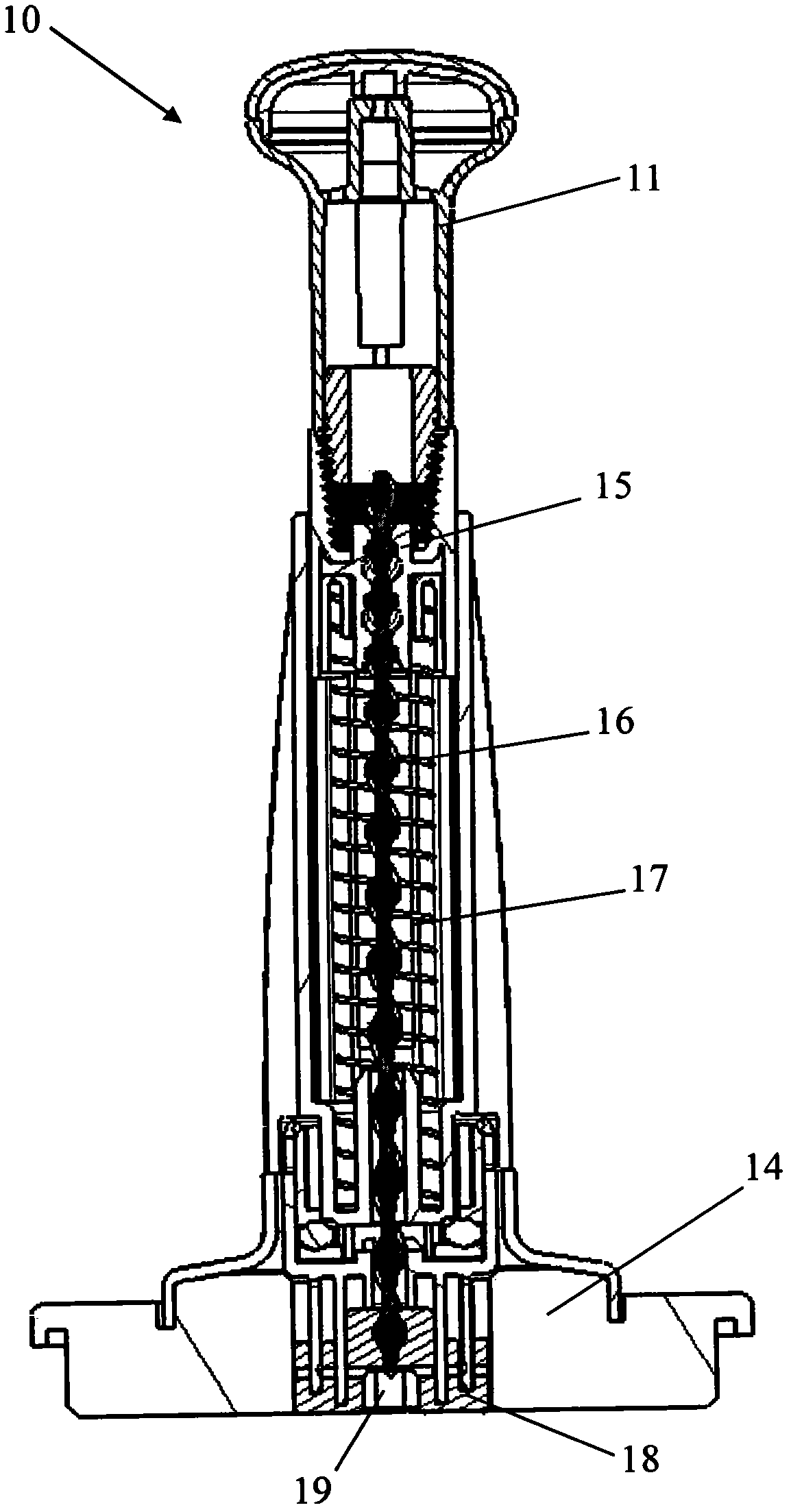

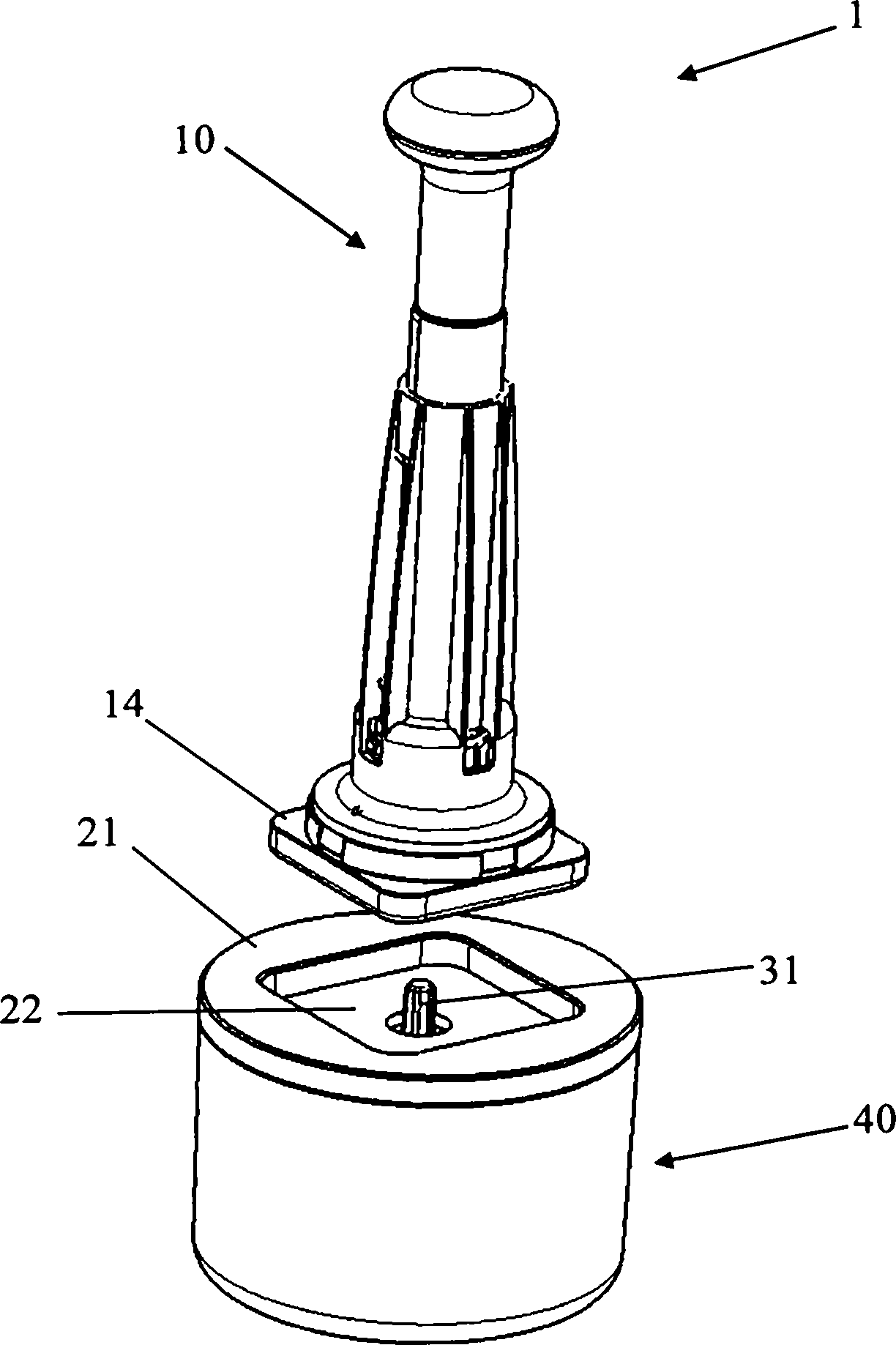

[0015] figure 1 The comminuting device 1 shown in an exploded view has a drive 10 , a partition unit 20 and a container 40 . The drive 10 has a rotationally fixed actuating device 11 , a coupling element 14 and a housing 13 arranged between the actuating device 11 and the coupling element 14 .

[0016] The handling device 11 has the shape of a pestle and is movable along the longitudinal axis of the drive device 10 . When the actuating device 11 is moved, it moves relative to the housing 13 which is immovable in the longitudinal direction. The coupling element 14 is detachably connected to the housing 13 .

[0017] The partition unit 20 has a partition element 21 which closes the container 40 . The separating element 21 has a recess 22 which has the same shape as the coupling element 14 of the drive device 10 . The recess 22 has an opening 23 which is dimensioned such that a coupling device 31 of a working unit 30 can pass through it.

[0018] In addition to the coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com