Waste liquid collection device, waste liquid discharge system and discharge method

A waste liquid discharge and waste liquid collection technology, which is applied in medical science, hospital equipment, nursing facilities, etc., can solve the problems of false alarms and missed alarms of liquid level detection devices, so as to improve accuracy, reduce missed alarms and false alarms The effect of the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

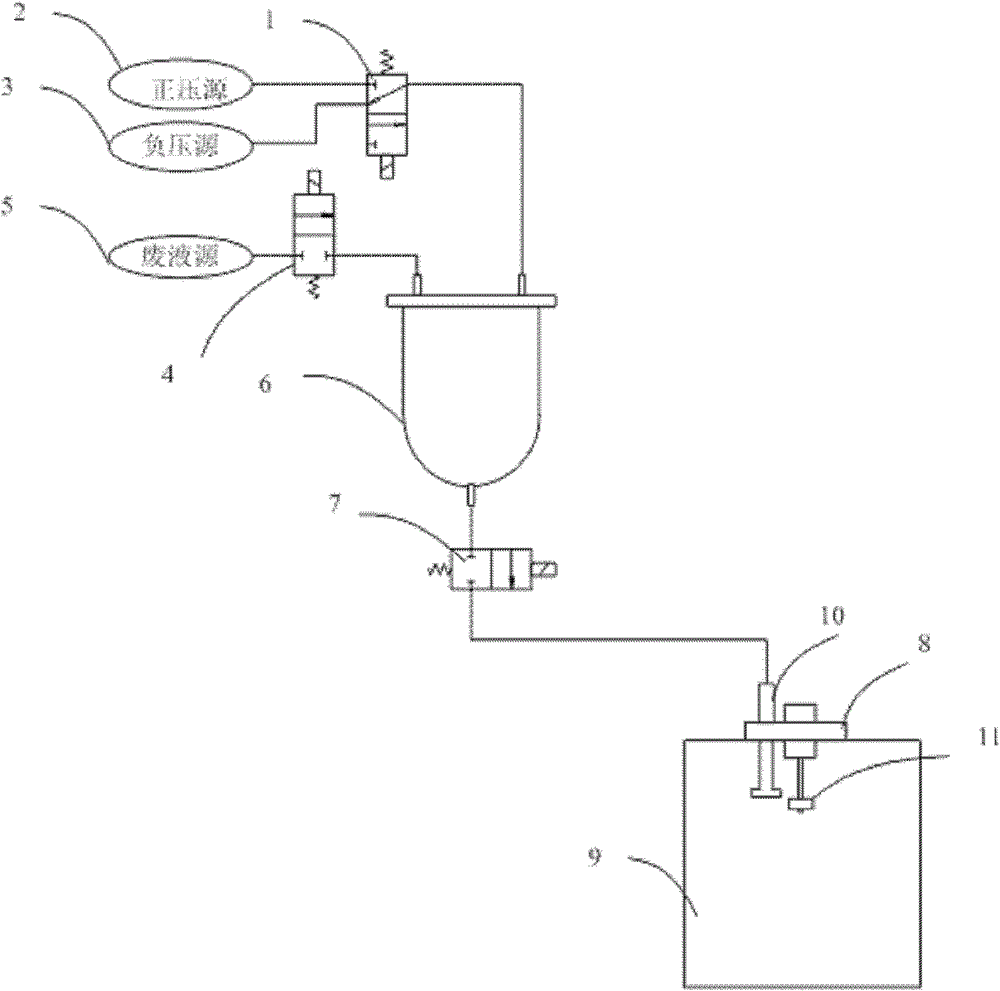

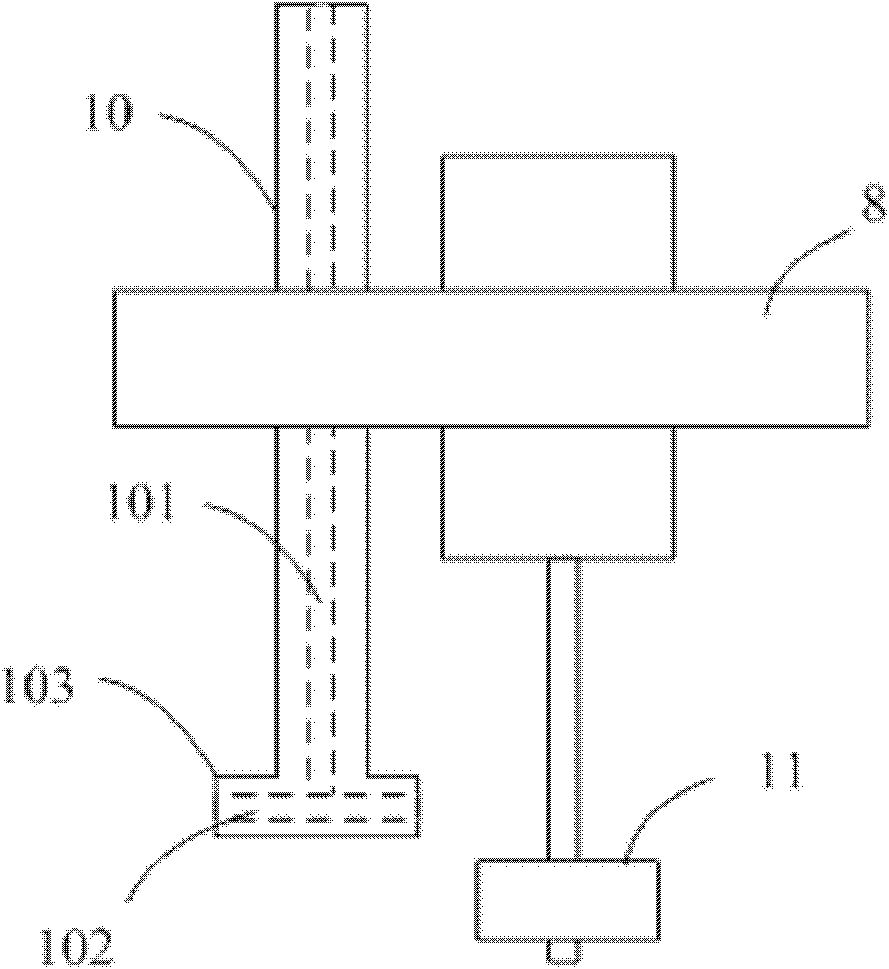

[0024] Please refer to figure 1 In the shown embodiment, the waste liquid discharge system includes: a pressure switching valve 1, a positive pressure source 2, a negative pressure source 3, a waste liquid source valve 4, a waste liquid source 5, a liquid storage tank 6, a waste liquid discharge valve 7 and a waste liquid A liquid collection device, the waste liquid collection device comprises a container 9, a waste liquid discharge joint 10 and a liquid level detection device 11, and the waste liquid discharge joint 10 and the liquid level detection device 11 are all arranged on the top of the container 9, such as the top or side of the container 9 upper edge of the wall. One end of the waste liquid discharge joint 10 communicates with the waste liquid discharge valve 7 , and the other end extends into the container 9 for discharging the waste liquid into the container 9 . The liquid level detection device 11 is used to detect the liquid level, and when the liquid level reac...

Embodiment 2

[0036] in such as image 3 In the shown embodiment, the waste liquid discharge joint 10 is different from the above-mentioned embodiments. In this embodiment, the shape of the waste liquid discharge joint 10 is "L" shape, that is, the bottom of the waste liquid discharge joint has a An outwardly extending arm 203, said arm 203 is arranged horizontally or substantially horizontally. A diversion hole 101 and a diversion hole 102 are opened inside the waste liquid discharge joint 10, the diversion hole 101 communicates with the diversion hole 102, the diversion hole 102 is opened in the arm 203, and the diversion hole 102 is also arranged horizontally or substantially horizontally . In this case, the discharge direction of the waste liquid is horizontal, and the flow of the waste liquid impinges on the inner side wall of the container.

Embodiment 3

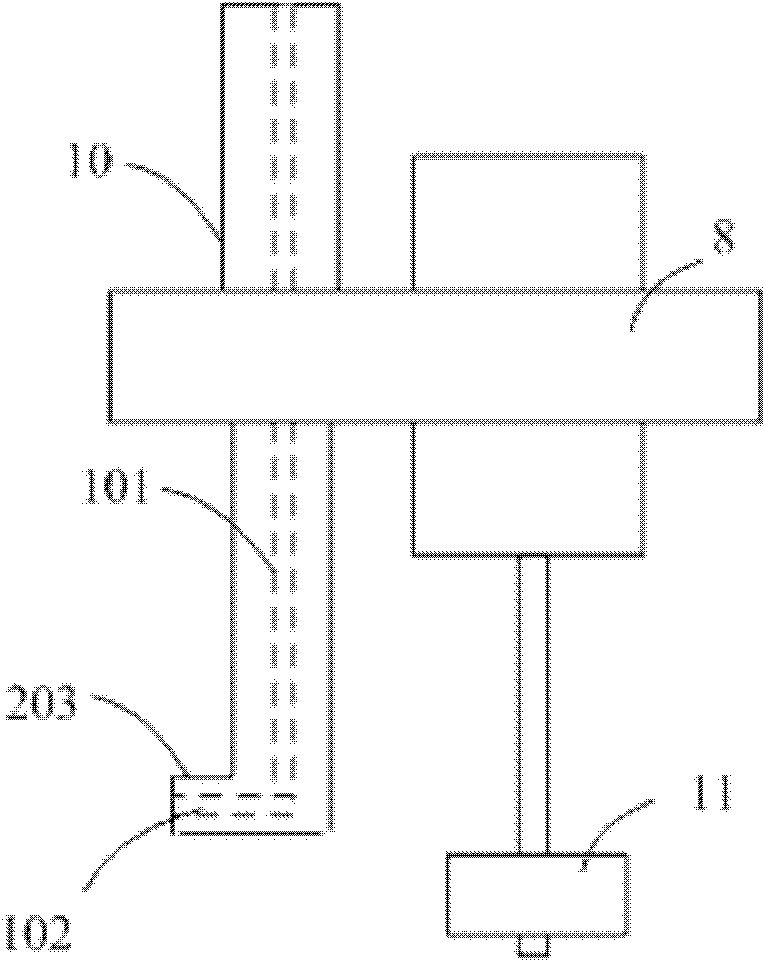

[0038] in such as Figure 4 In the shown embodiment, the shape of the waste liquid discharge joint 10 is an approximate "L" shape, that is, the bottom of the waste liquid discharge joint has an arm 303 extending outward from the side wall, and the arm 303 is at a certain angle to the horizontal direction. An included angle, the included angle may be an angle greater than 0° and less than 60°, such as 30° or 50°. The direction changing hole 102 is opened in the arm 303, and the angle between the axis direction of the direction changing hole 102 and the horizontal line is also in the range of 0° to 60°, such as 30° or 50°. In this case, the discharge direction of the waste liquid is obliquely upward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com