Positive end expiratory pressure (PEEP) safety protection system and method thereof

A safety protection and safety technology, applied in the field of medical electronics, can solve problems such as difficulty in exhalation, insufficient safety factor, suffocation danger, etc., and achieve the effect of reducing air source loss, ensuring patient safety, and high safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

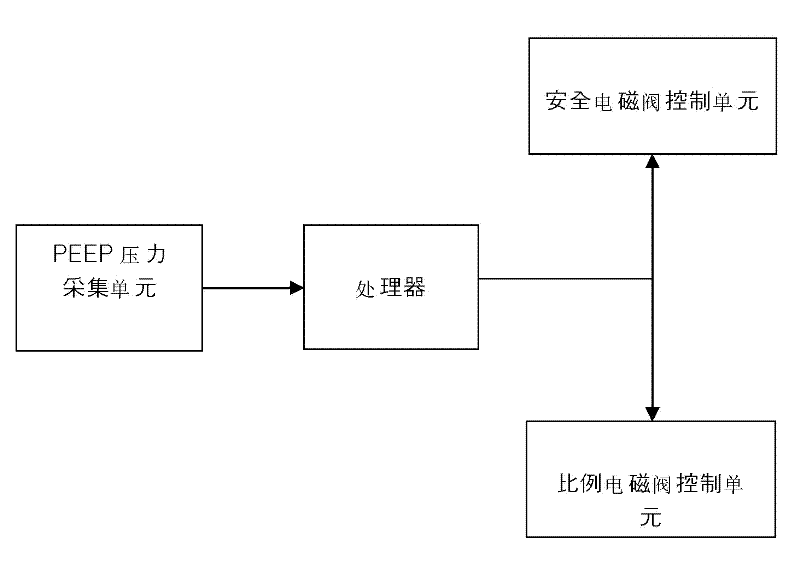

[0026] The PEEP safety protection system of the specific embodiment of the present invention, the circuit structure is as follows figure 1 As shown, it includes a processor and a PEEP pressure acquisition unit electrically connected to it, a proportional solenoid valve control unit and a safety solenoid valve control unit, wherein the PEEP pressure acquisition unit is a pressure sensor installed on the breathing pipeline connecting the user and the PEEP valve. sensor.

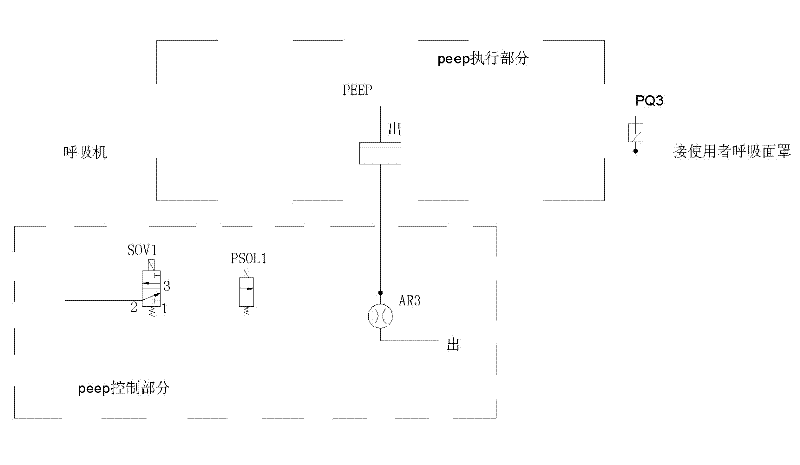

[0027] The PEEP safety protection system, the air circuit structure is as follows figure 1 As shown, it includes a proportional solenoid valve PSOL1 and a safety solenoid valve SOV1 connected in series with the pneumatic control end of the PEEP valve PEEP in series on the control air circuit, and the pneumatic control is connected to the ventilator and the user's PEEP valve; the pneumatic control end of the PEEP valve is also Through the air resistance AR3 bypass conduction, the air is always exhausted during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com