Improved type device for regulating driving force of coating roll

A technology for adjusting devices and coating rollers, which is applied to the device for coating liquid on the surface, coating, etc., and can solve the problems of easy slippage, pressure, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

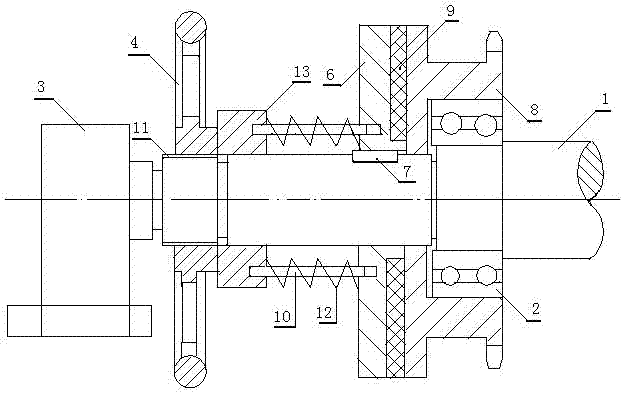

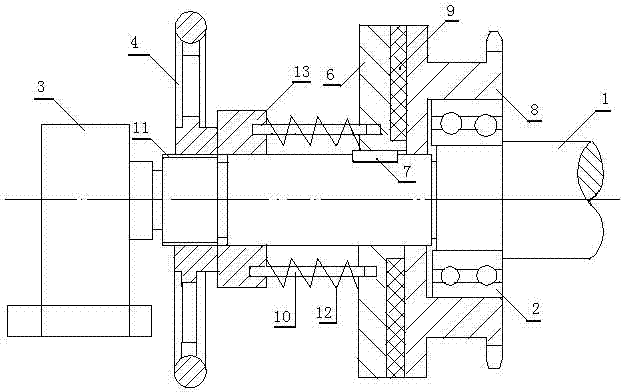

[0008] As shown in the figure, an original coating roller driving force adjustment device includes a coating roller 1, a rolling bearing 2, a bearing seat 3, an adjustment wheel 4, a sliding seat 6, a flat key 7, a power sprocket 8, a friction plate 9 and Thread 11, coating roller 1 is sleeved with rolling bearing 2, coating roller 1 rotates with bearing seat 3 through rolling bearing 2, and power sprocket 8 is set on coating roller 1, and through rolling bearing 2 and coating roller 1 Movable cooperation, the left side of the power sprocket 8 is connected with a sliding seat 6, the sliding seat 6 is matched with the coating roller 1 through the flat key 7 to slide left and right, and the rotation is stationary, and the right side of the sliding seat 6 is connected to the power chain through the friction plate 9 The wheel 8 is in friction fit, and the coating roller 1 is also provided with an adjustment wheel 4, which is adjusted and matched with the coating roller 1 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com