Horizontal evaporative concentration system

An evaporative concentration system and evaporative concentration technology, applied in the direction of heating water/sewage treatment, etc., can solve the problems of difficult back-evaporation, low evaporation efficiency, easy leakage of pipes, etc., and achieve the goal of avoiding back-evaporating pollution, simple structure, and avoiding blockage of pipes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

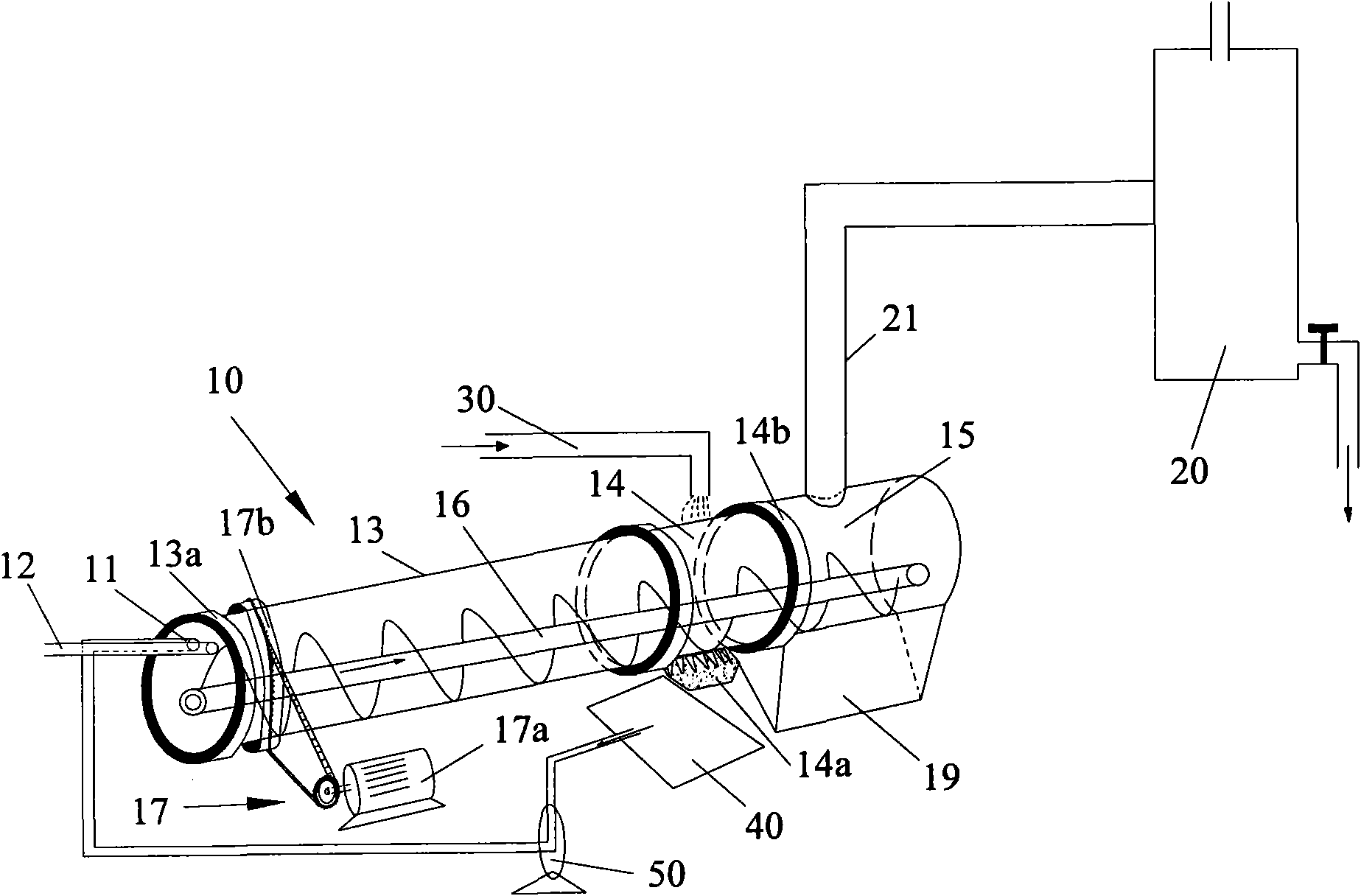

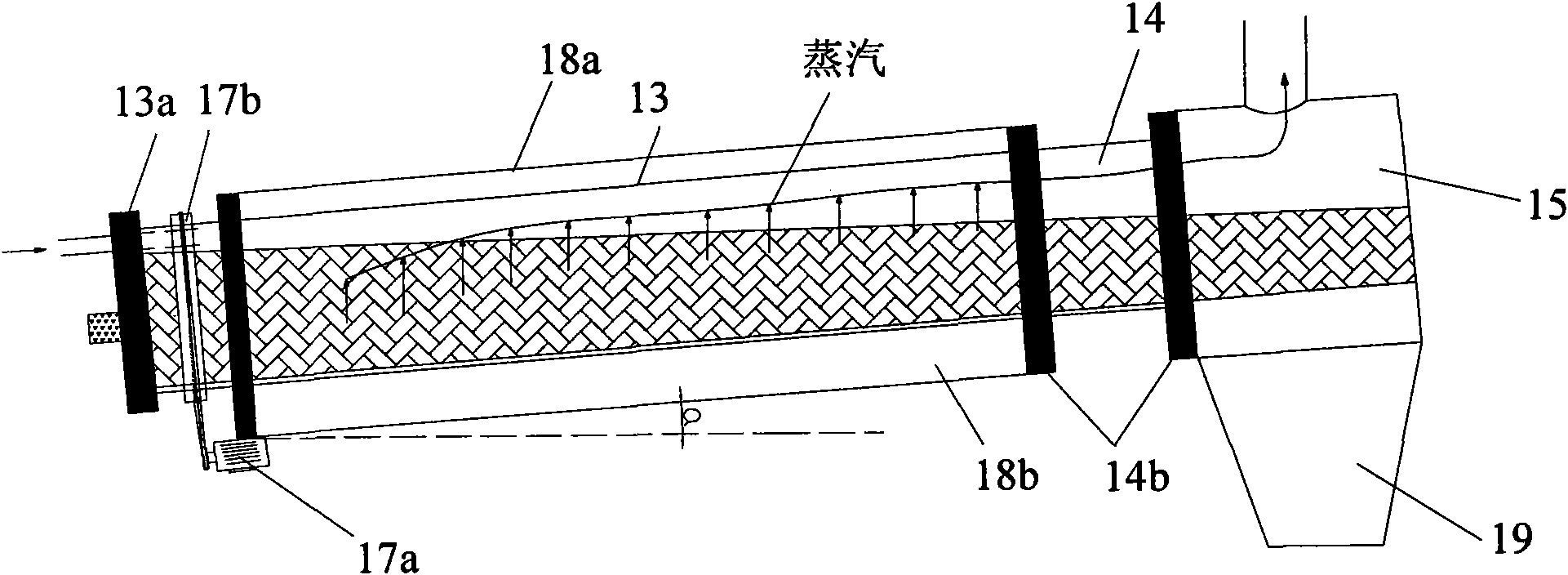

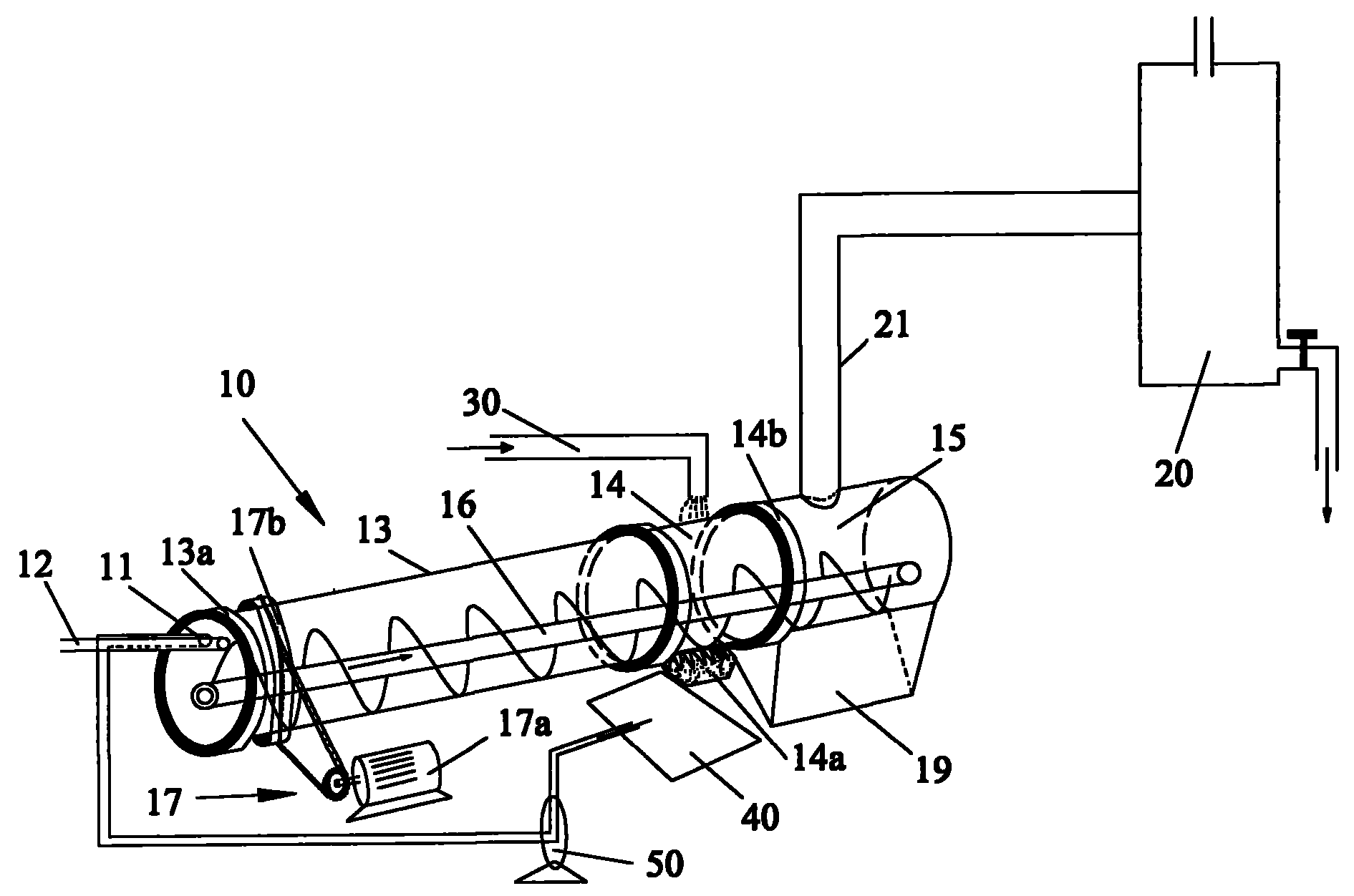

[0039] The horizontal evaporative concentration system of the present invention includes an evaporative concentration device 10 and a gas-liquid separator 20, the evaporative concentration device 10 includes a water supply pipe 11, a drug supply pipe 12, a horizontal rotating cylinder 13, a cooling bin 14, a separation bin 15, The screw feeding part 16, the drive part 17 for rotating the horizontal rotating cylinder 13 and the heating part 18 for heating the horizontal rotating cylinder 13, the water supply pipe 11 and the drug supply pipe 12 respectively The horizontal rotating cylinder 13 provides raw water and pharmaceuticals, the cooling bin 14 is connected ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap