Bricklaying loading method of coke oven

A coke oven and masonry technology, which is applied in coke oven bricklaying operations, etc., can solve problems such as uneven size of ash joints, inability to ensure consistency and uniformity of ash joints, damage to furnace wall brick joints and mud strength, etc., to achieve Protect the strength of mud, improve masonry quality and work efficiency, and ensure the uniformity and consistency of mortar joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

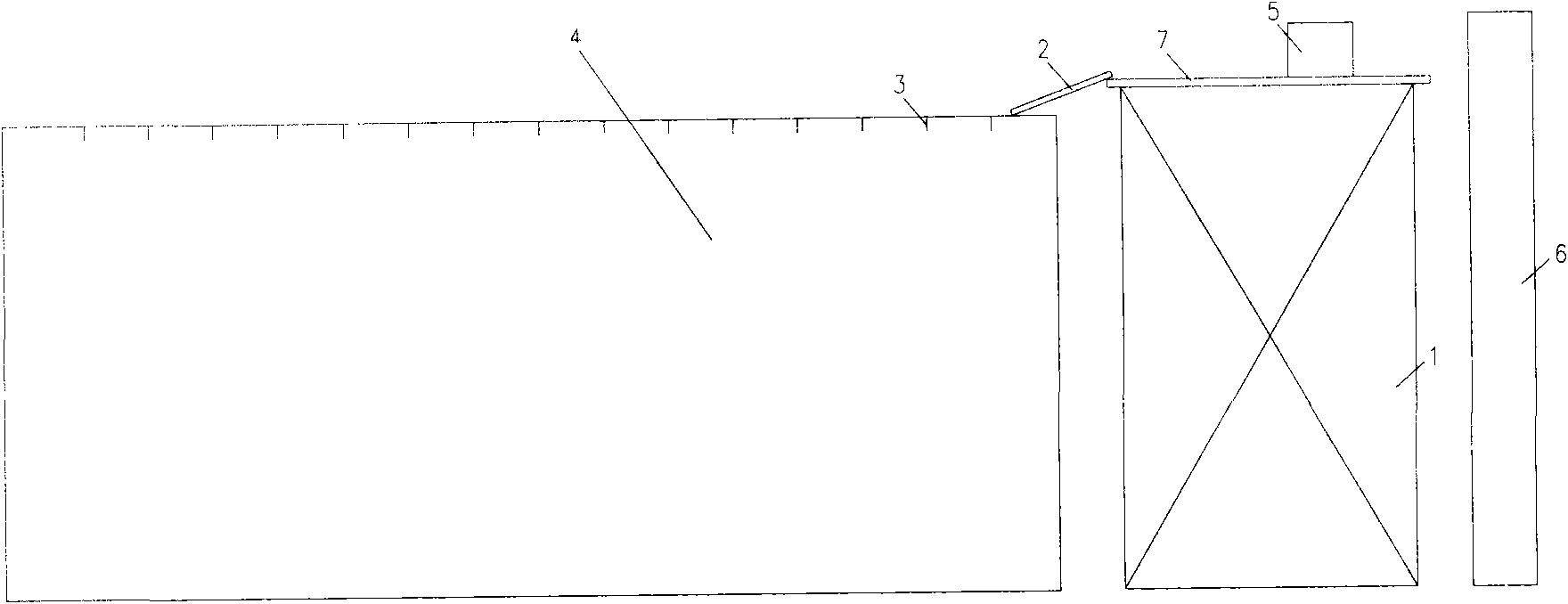

[0026] see now figure 1 , figure 1 It is a schematic diagram of the device setup and operation of the embodiment of the present invention.

[0027] The coke oven masonry receiving method of the present invention is applied to 55-hole 6m coke oven masonry. The whole furnace has 56 combustion chambers in total. The furnace body includes a foundation platform, a regenerator, a ramp, a combustion chamber and a furnace roof; 12340mm, width 15980mm, length 75200mm; the width direction of the furnace body is divided into machines and coke sides, and the side close to the coke pushing machine is the machine side, which is characterized in that it includes the following steps:

[0028] a. Set up a load-bearing platform 1, and use fasteners and scaffolding to build an independent load-bearing platform 1 outside the coke oven body. The distance between the load-bearing platform 1 and the coke oven body is 0.5m. There are multiple sections on the top of the load-bearing platform, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com