PVC (polyvinyl chloride) plastic floor with conducting layer

A technology of polyvinyl chloride and plastic flooring, applied to floors, buildings, building structures, etc., to achieve the effect of enhancing electrical conductivity and preventing electromagnetic leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

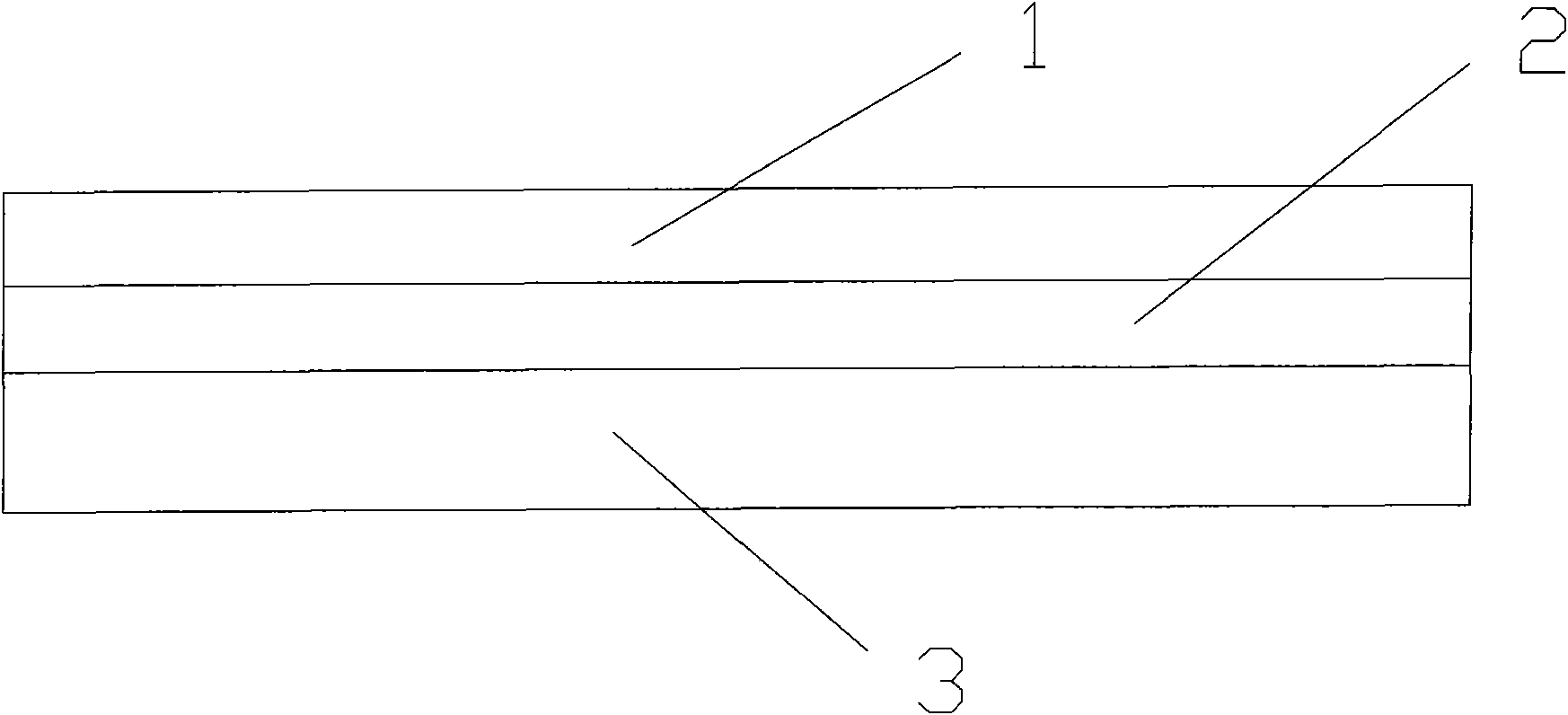

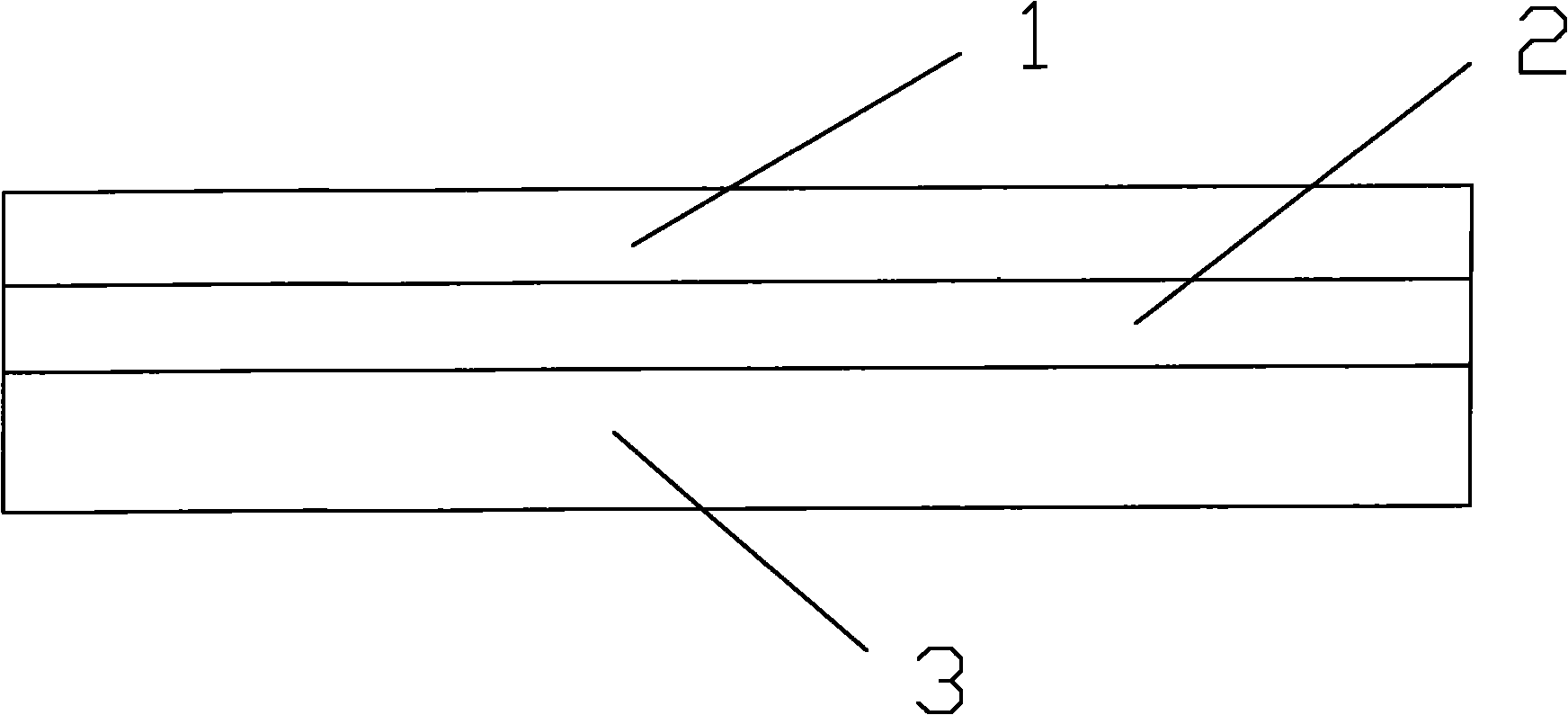

[0011] A polyvinyl chloride plastic floor with a conductive layer, which is characterized by comprising a conductive layer 1, a PVC layer 2, and a composite reinforcement layer 3; from top to bottom, there are conductive layer 1, PVC layer 2, and composite reinforcement layer 3; The conductive layer 1 is composed of metal wire mesh; the PVC layer 2 contains conductive carbon black. The composite reinforcement layer 3 is composed of a non-woven fabric layer and an adhesive layer; the film is composed of polyperfluoroethylene propylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com