Valve core of butterfly valve

A spool and butterfly valve technology, applied in the field of butterfly valve spools, can solve problems such as bad effects of durability, increase of bad effects, and poor productivity, and achieve the effects of ensuring strength, improving flow characteristics, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

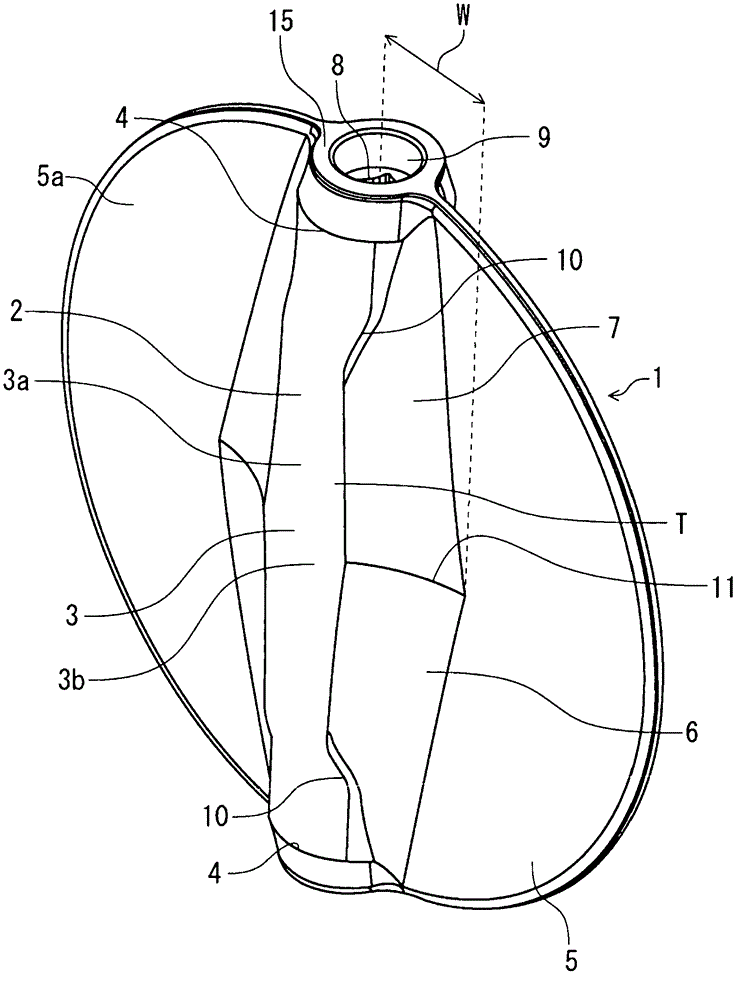

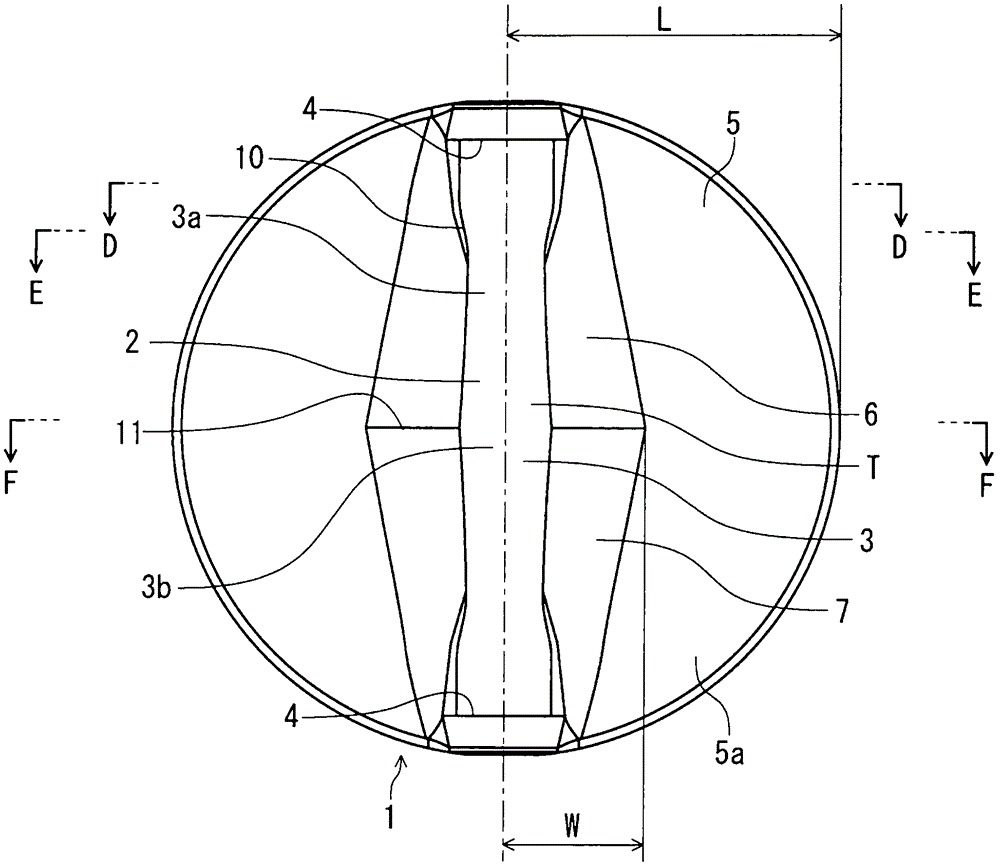

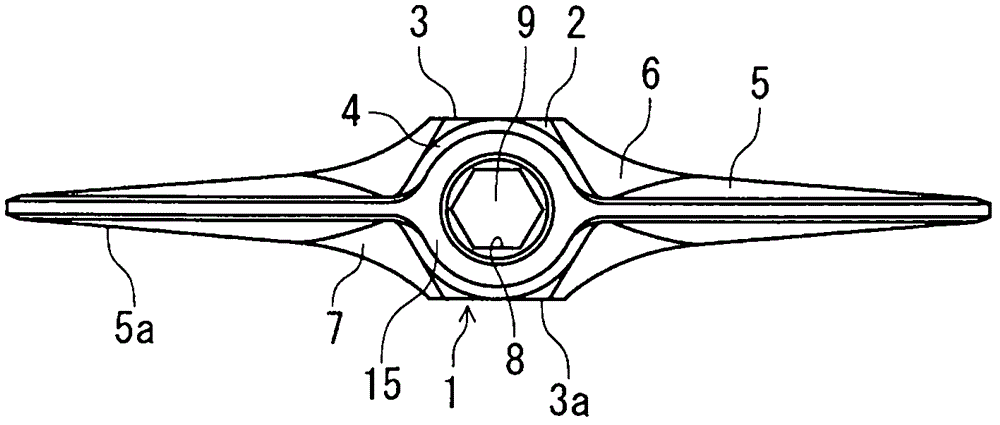

[0037] Hereinafter, preferred embodiments of the valve core of the butterfly valve in the present invention will be described in detail with reference to the drawings. figure 1 In, the perspective view of the spool of the butterfly valve in the present invention is shown, figure 2 in, means figure 1 top view of image 3 in, means figure 2 top view. Image 6 , shows a more detailed perspective view of the valve element of the butterfly valve of the present invention.

[0038] As shown in the figure, the valve core 1 of the butterfly valve in the present invention is formed into a disc shape, and is in the shape of a boss part 2 arranged continuously in the longitudinal direction from the top to the bottom, and the boss part 2 forms a cylindrical cross-sectional hexagon Part 3, cross-sectional circular part 4, and the boss part 2 and the valve leaf part 5 of the valve core 1 are connected by a connecting R part 7 with a gradual change R6.

[0039] In the valve core 1 of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap