Camera module

A camera module and lens array technology, which is applied in installation, television, optics, etc., can solve the problems of increasing the total length of the optics and the thickness of portable electronic devices, and achieve the effect of small thickness and shortening the total length of the optics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution will be further described in detail below in conjunction with the accompanying drawings and embodiments.

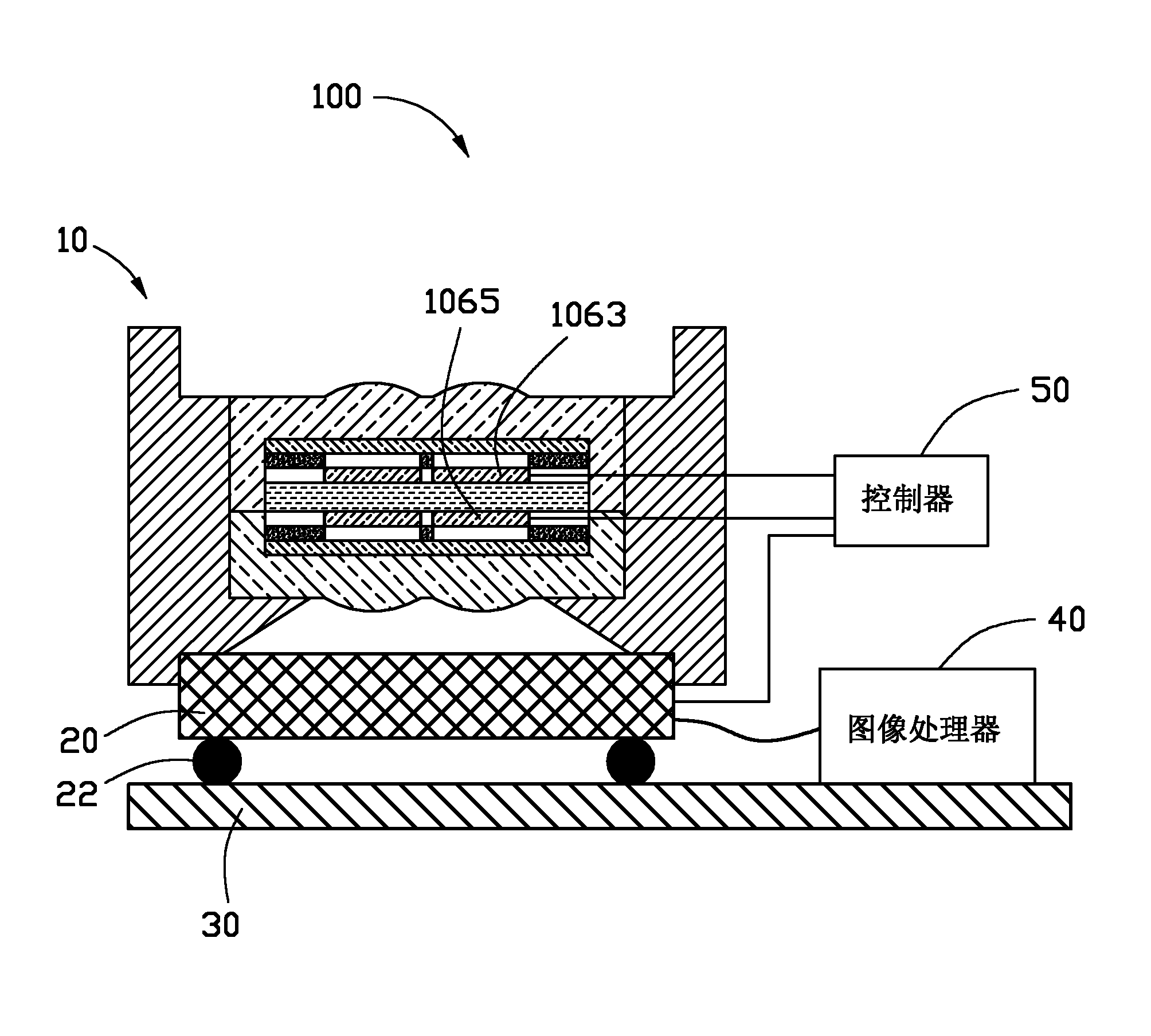

[0042] see figure 1 , a preferred embodiment of the present invention provides a camera module 100 . The camera module 100 includes a composite lens 10 , a controller 50 , an image sensor 20 , an image processor 40 and a circuit board 30 . The image sensor 20 is soldered on the circuit board 30 through solder balls 22 . The image processor 40 is provided on the circuit board 30 . The image sensor 20 is electrically connected to the controller 50 and the image processor 40 respectively.

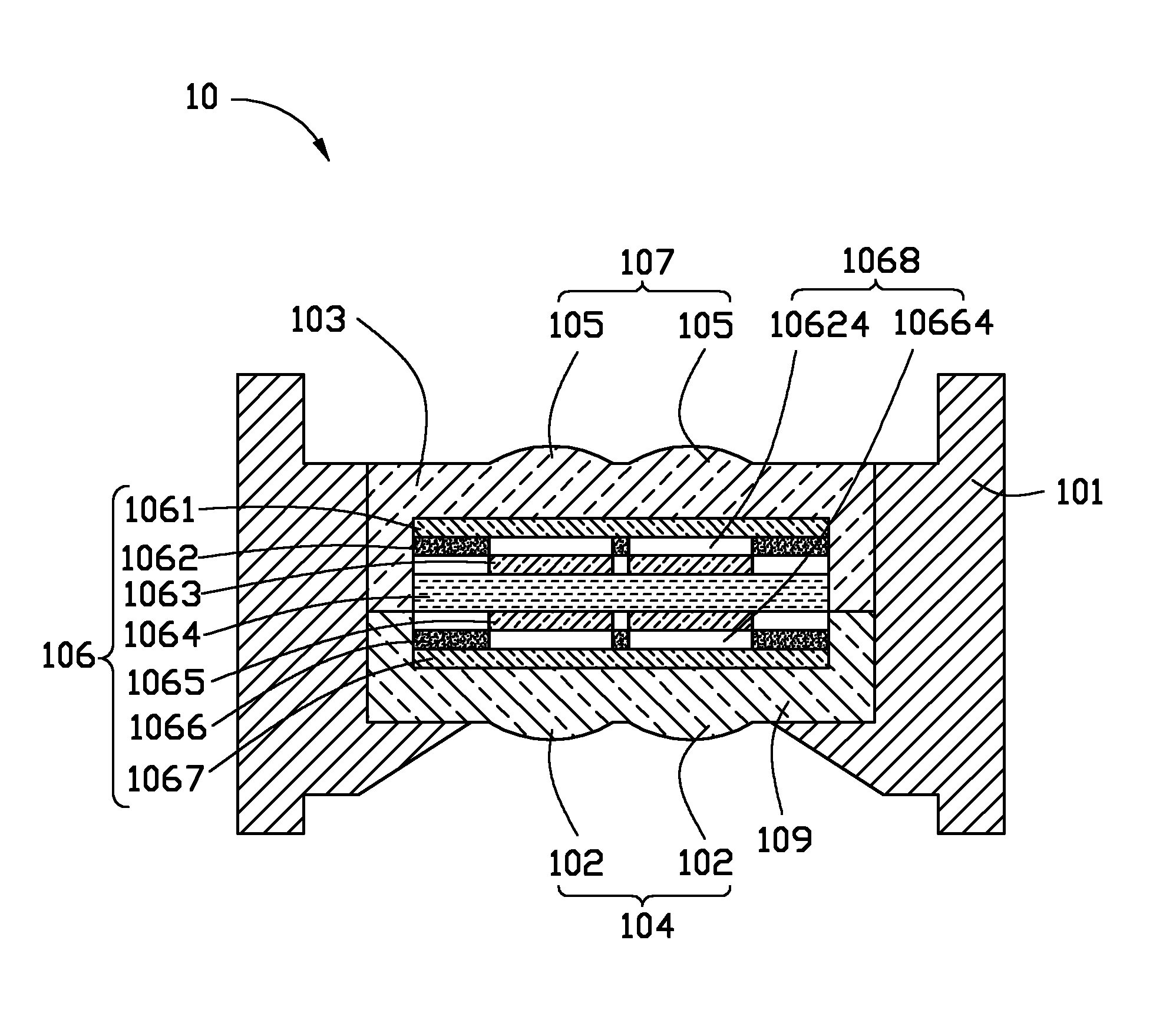

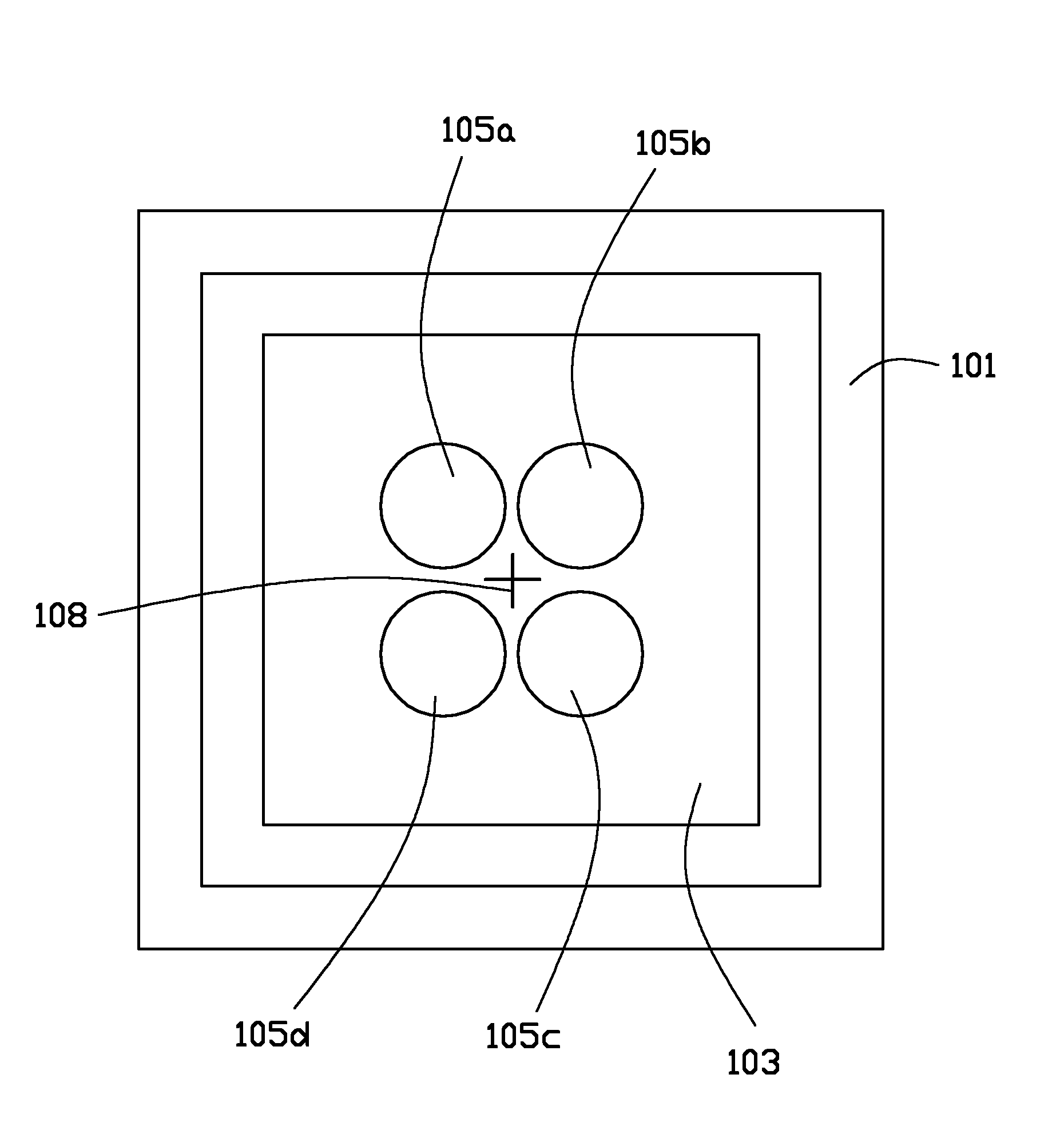

[0043] see figure 2 and image 3 , the composite lens 10 includes a mirror frame 101, an upper substrate 103, a lower substrate 109, a first lens array 107 formed on the upper substrate 103, a second lens array 104 formed on the lower substrate 109, and a lens array sandwiched between the upper substrate 103 and the lower substrate 109 between the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com