Liquid crystal display (LCD) panel and manufacturing method of color filter substrate thereof

A technology of liquid crystal display panels and color filter substrates, applied in optics, nonlinear optics, instruments, etc., can solve problems such as easy light leakage and adverse effects on the display performance of liquid crystal display panels, so as to achieve difficult displacement, improve display performance, prevent The effect of side light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

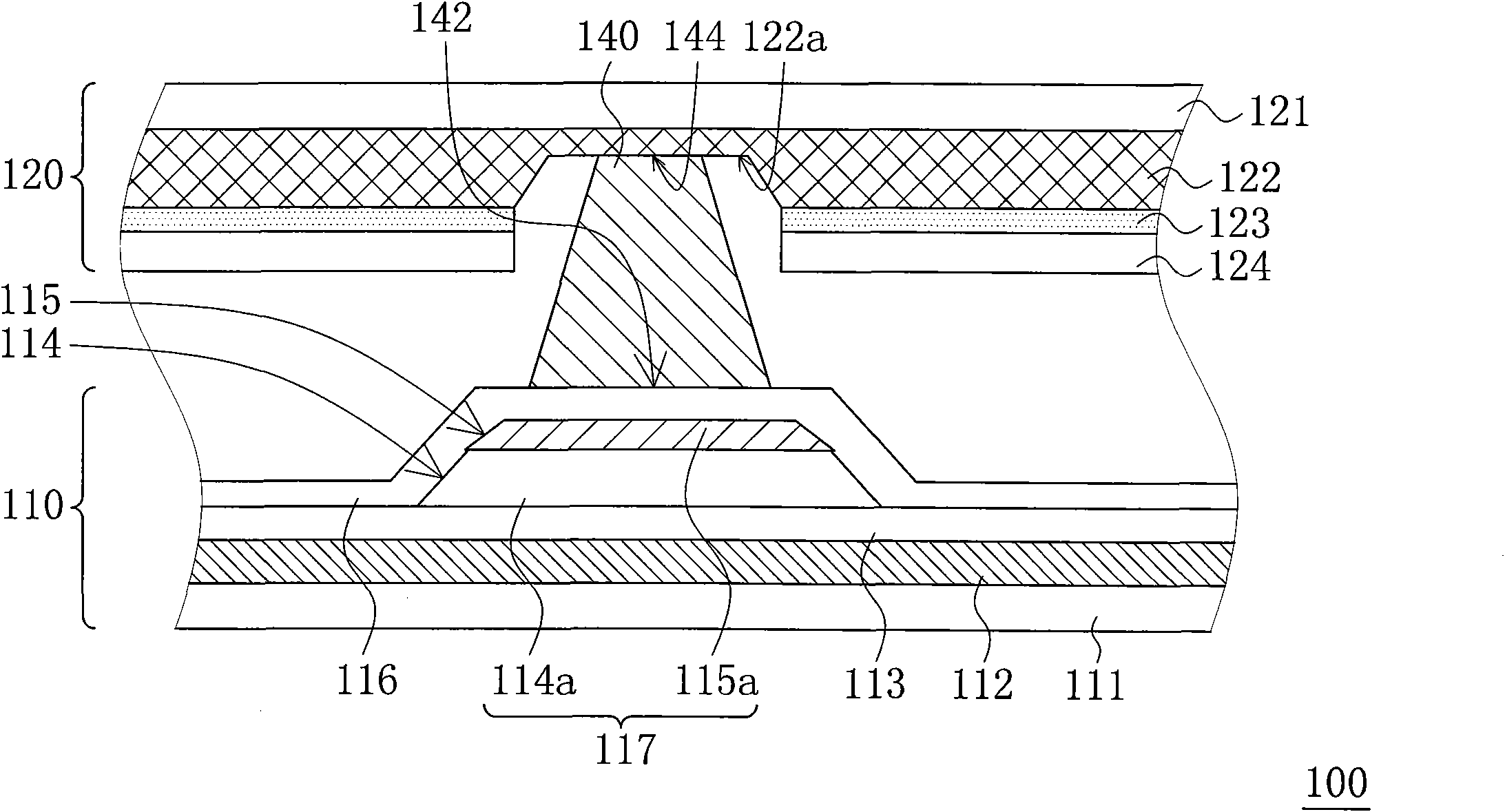

[0014] figure 2 is a partial cross-sectional schematic view of the liquid crystal display panel according to the first embodiment of the present invention. The liquid crystal display panel 100 includes an active device array substrate 110 , a color filter substrate 120 , a liquid crystal layer (not shown in the figure) and a plurality of optical spacers 140 . The liquid crystal layer is disposed between the active device array substrate 110 and the color filter substrate 120 . The active device array substrate 110 may be a thin film transistor array substrate, but not limited thereto. The active device array substrate 110 includes a first substrate 111 and a plurality of film layers formed on the first substrate 111 (such as a first metal layer 112, an insulating layer 113, a semiconductor layer 114, a second metal layer 115 and a protective layer 116), The film layers are stacked on the first substrate 111 to form a plurality of protruding support portions 117 . In more d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap