Edge occlusion-packaged light guide film and processing die and processing method thereof

A technology for processing molds and processing methods, which is applied in the field of light guide films, can solve the problems of reduced bonding area of black and white double-sided adhesive tape, dark brightness of display screen or key characters, and large shrinkage of light guide films, so as to improve the effective Utilization rate, avoiding cracking, good effect of preventing side light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

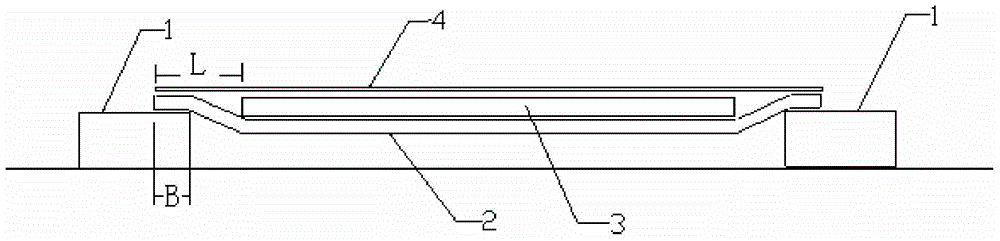

[0025] A light guide film for side bite packaging, the structure of which is as follows figure 1 As shown in , it includes a light-guiding base film 3, and black and white double-sided adhesive tape 4 and black-and-white film 1 located on the upper and lower sides of the light-guiding base film 3 respectively. The edge of the film 2 is retracted from one end to a distance L. In this example, L is 0.8mm. The black and white double-sided adhesive tape 4 and the black and white film 2 are occluded in the retracted area of the light guide base film 3, and the width of the occlusal contact surface of the two is B. And B=1 / 2~3 / 4L, in this example, the occlusal width B is 0.6mm, and the black and white film 1 has a "Z"-shaped cross section at the occlusion (in this example, if the black and white film 1 is located on the light guide base during processing On the upper side of the film 1, the black and white double-sided adhesive tape 4 is in a "Z" shape in cross-section at the join...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap