Electronic ink screen capable of preventing light leakage

An electronic ink screen and anti-light leakage technology, applied in optics, nonlinear optics, electrical digital data processing, etc., can solve the problems of high haze and roughness, low definition, and inability to solve the problem of light leakage through gaps, etc., to achieve enhanced protection effect , good display effect, the effect of gaining visual experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

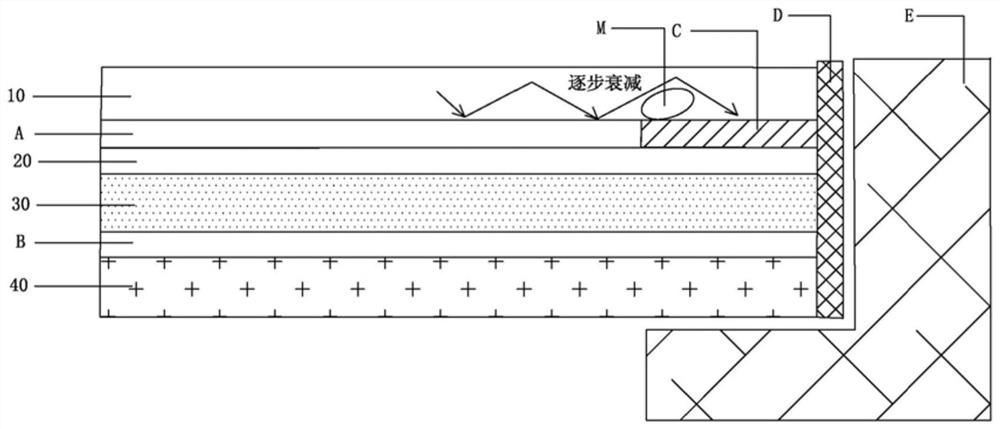

[0028] Such as figure 1 As shown, a light-leakage-proof electronic ink screen includes: a glass touch panel 10, a touch sensing layer 20, a light guide plate 30, and an ink display 40 arranged sequentially from the surface to the inside, the glass touch panel 10 and A first optical adhesive layer A is arranged between the touch sensing layers 20, and a first dark paint layer C is coated on the light leakage area M of the first optical adhesive layer A. On the glass touch panel 10, The side surfaces of the touch sensing layer 20 , the light guide plate 30 and the ink display screen 40 are further provided with a second dark paint layer D, and the second dark paint layer D is arranged from the surface to the inside.

[0029] In this embodiment, the light leakage area M of the first optical adhesive layer A is coated with the first dark paint layer C, so as to weaken the reflection and transmission of light to a large extent; in the glass touch panel 10 The sides of the touch se...

Embodiment 2

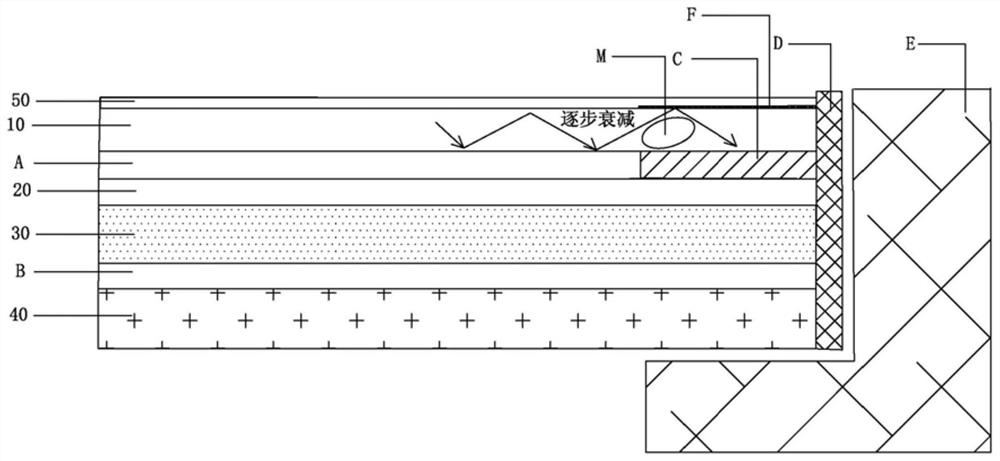

[0040] Such as figure 2 As shown, an electronic ink screen that prevents light leakage, this embodiment is also provided with an anti-glare AG film 50 on the basis of the first embodiment above.

[0041]Specifically: in this embodiment, the glass touch panel 10, the touch sensing layer 20, the light guide plate 30, and the ink display screen 40 are sequentially arranged from the outside to the inside, the glass touch panel 10 and the touch sensing layer 20 The first optical adhesive layer A is arranged between them, the light leakage area M of the first optical adhesive layer A is coated with the first dark paint layer C, and the glass touch panel 10, the touch sensing layer 20, the light guide plate 30 and the side of the ink display screen 40 are also provided with a second dark paint layer D, and the second dark paint layer D is arranged from the surface to the inside.

[0042] In this embodiment, a thin layer of AG film 50 is also configured, and the AG film 50 covers th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap