Fully-automatic production line for high definition multimedia interface (HDMI) connector

A fully automatic, production line technology, applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problems of low production efficiency, HDMI connector does not realize assembly line operation, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

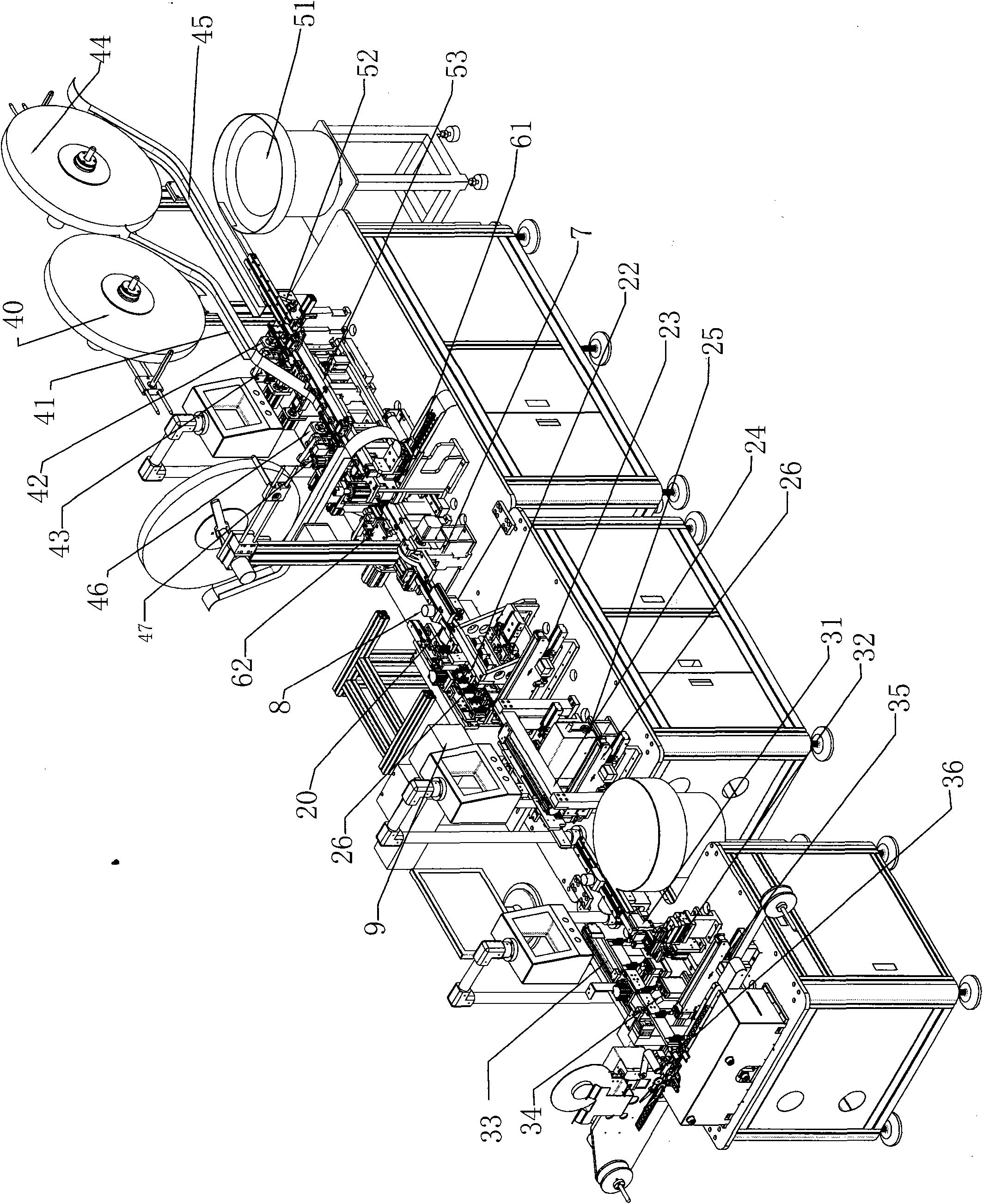

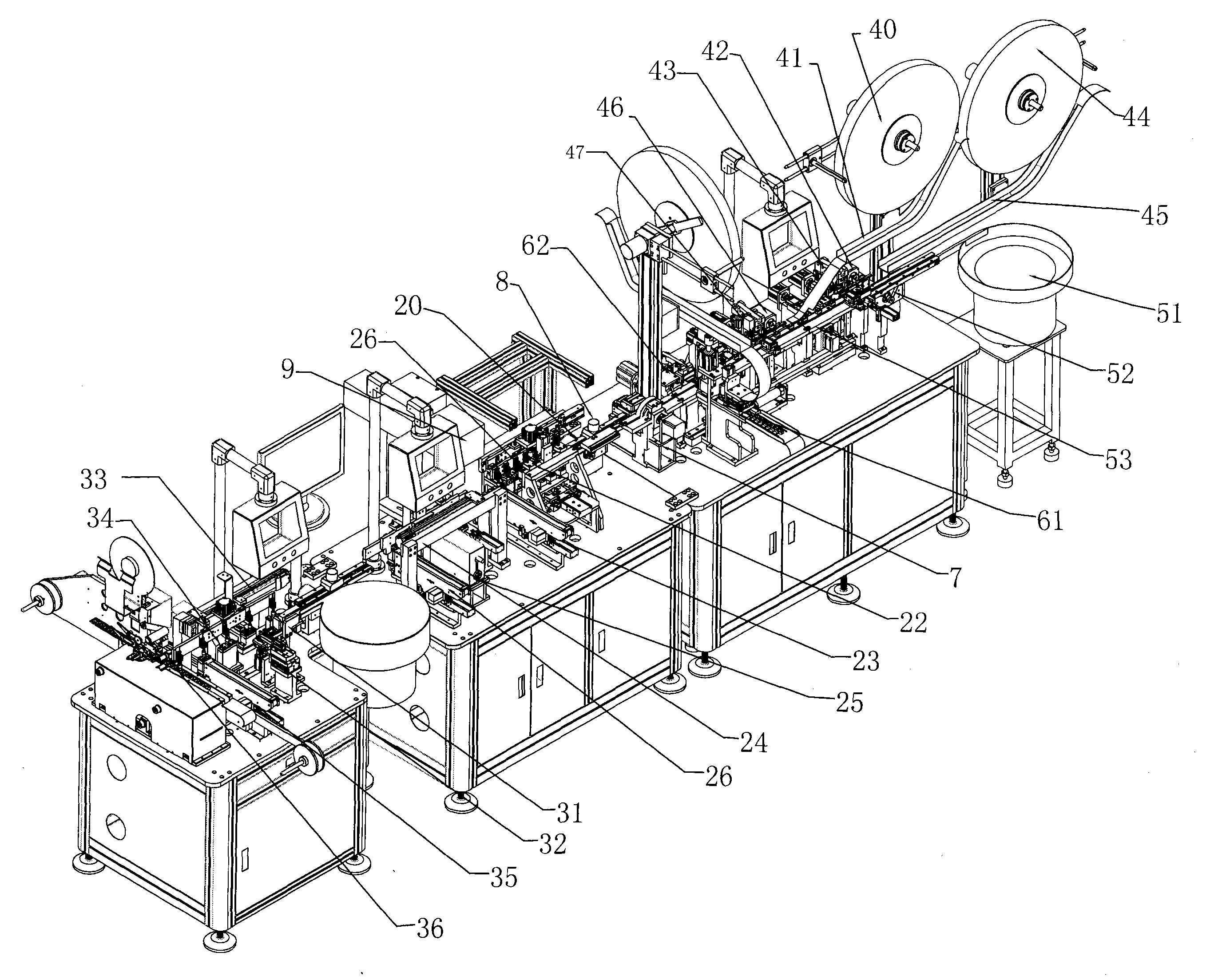

[0015] Such as figure 1 As shown, a fully automatic production line for HDMI connectors, which includes a product forming part 1, a product testing part 2, and a dust cover installation and product packaging part 3. The product forming part includes a terminal feeding mechanism 4, a plastic body feeding Feeding mechanism 5 and iron shell feeding mechanism 6;

[0016] The product detection part 2 includes a conduction withstand voltage testing mechanism 22, a first CCD detection mechanism 25, a product connection conveyor belt 20, a first defective product screening mechanism 23, a first servo motor displacement mechanism 24, and a second defective product screening mechanism. Mechanism 26, the product connecting conveyor belt 20 is set betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com