Positioning mechanism of rail guided vehicle for rear axle assembling line of commercial vehicle

A positioning mechanism and assembly line technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of inaccurate positioning, assembly errors, reference changes, etc., and achieve the effect of protecting life safety, saving assembly time, and reducing collision impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

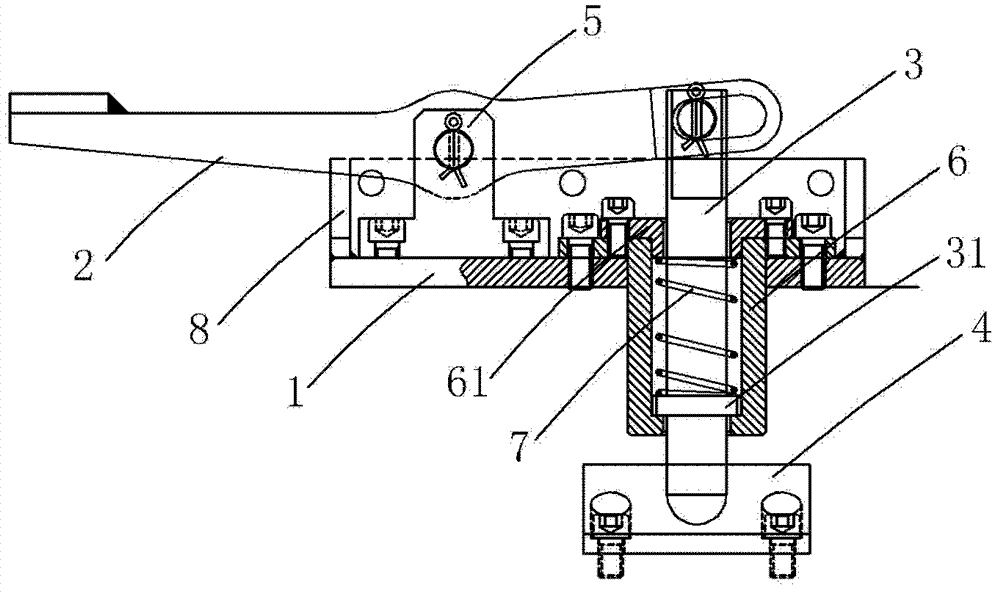

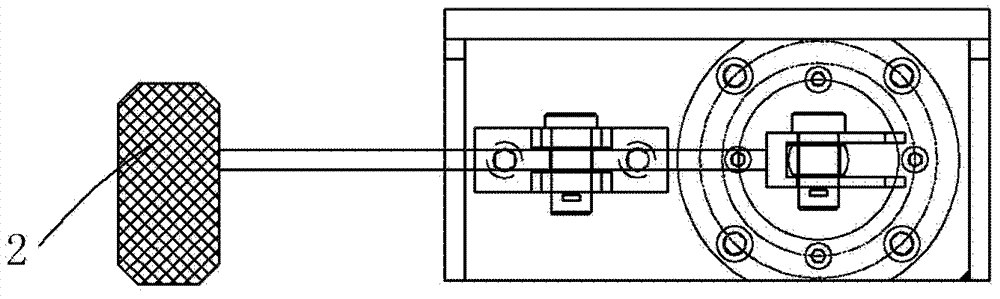

[0027] Example: see figure 1 , 2 , the trolley positioning mechanism of the commercial vehicle rear axle assembly line of the present embodiment includes:

[0028] A mounting base 1 is fixedly installed on the side of the trolley, and a convex pedal base 5 is fixedly connected to the mounting base 1. The fulcrum of the lever pedal 2 is hinged on the pedal base 5 through a pin shaft, and a positioning pin is hinged at the front end of the pedal 2. Axis 3.

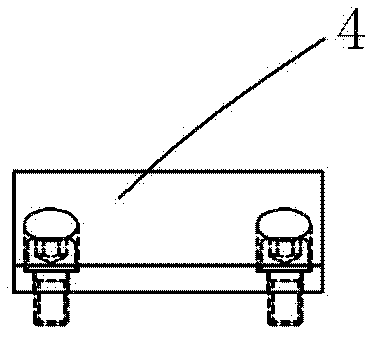

[0029] As shown in Figure 3, a positioning block 4 is fixedly arranged on the ground, and a U-shaped groove matching the bottom end of the positioning shaft is arranged on the positioning block to form a positioning for the positioning shaft. Some are sloped.

[0030] The trolley positioning mechanism is provided with a guiding and reset mechanism for the positioning shaft. The specific structure is: a positioning shaft sleeve 6 is fixed on the installation base 1, and the bottom end of the positioning shaft extends from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com