Winder station and operation method for station

A winding machine and station technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., and can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

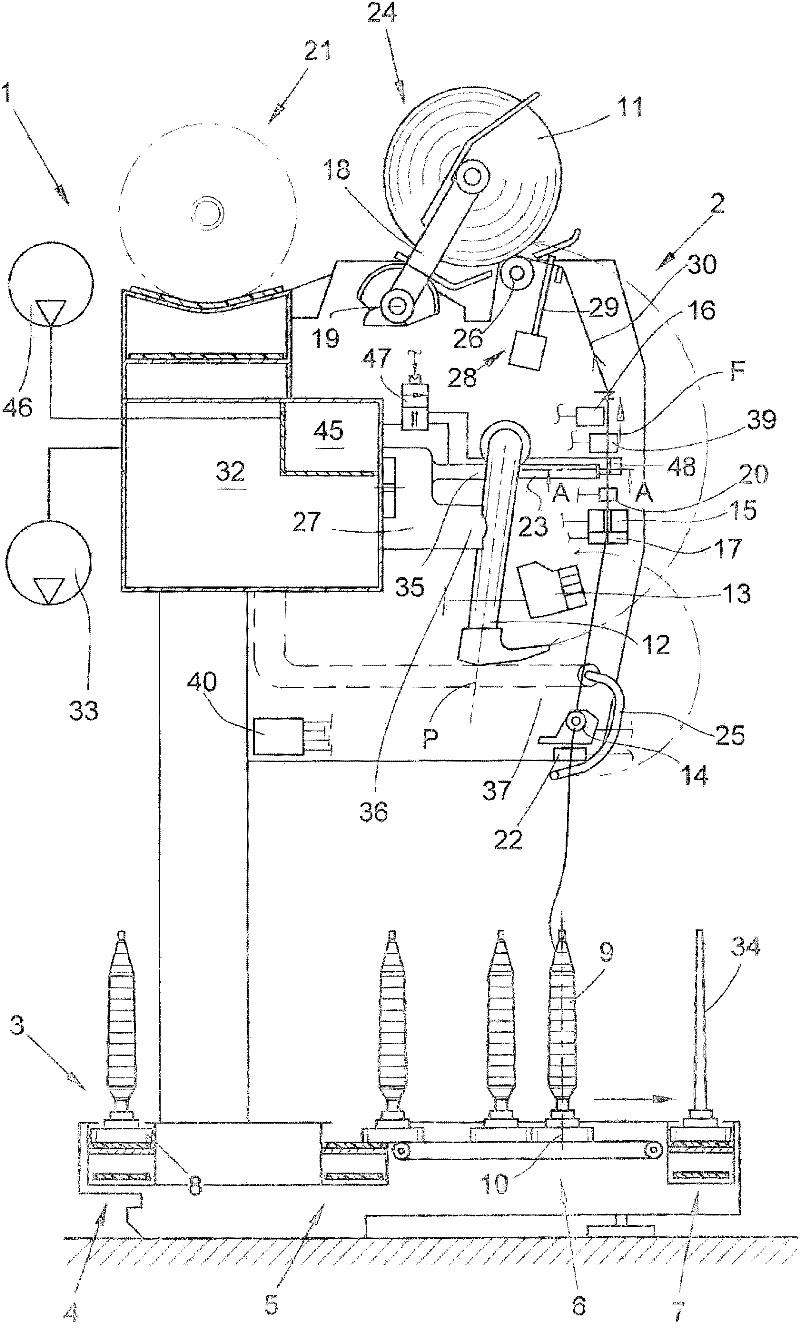

[0019] figure 1 The station 2 of the winder 1, which in this embodiment is a so-called automatic crosswinding winder, is shown in a schematic side view during the winding process. Such an automatic cross-winding winder 1 has a number of identical stations 2 between its end frames (not shown), so-called winding positions.

[0020] In these winding positions 2, the feeding bobbins, which are generally produced on ring spinning machines with relatively small amounts of yarn material 9, are rewound into large packages as is well known and therefore not described in detail. The cross-wound bobbin 11. The produced cross-wound bobbins 11 are then handed over to the cross-wound bobbin conveyor 21 along the length of the machine by means of an automatically operating service unit, such as a cross-wound bobbin changer, and sent to the machine end side. Package loading station, etc.

[0021] Furthermore, this automatic cross-wound winder is either equipped with a circular magazine in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap