Pin moving device, movable connecting structure and suspension hook structure

A technology for moving devices and pin shafts, which is applied in the field of machinery, can solve the problems of difficult installation of pin shafts and high friction, and achieve the effects of small installation difficulty, reduced friction, and labor-saving installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

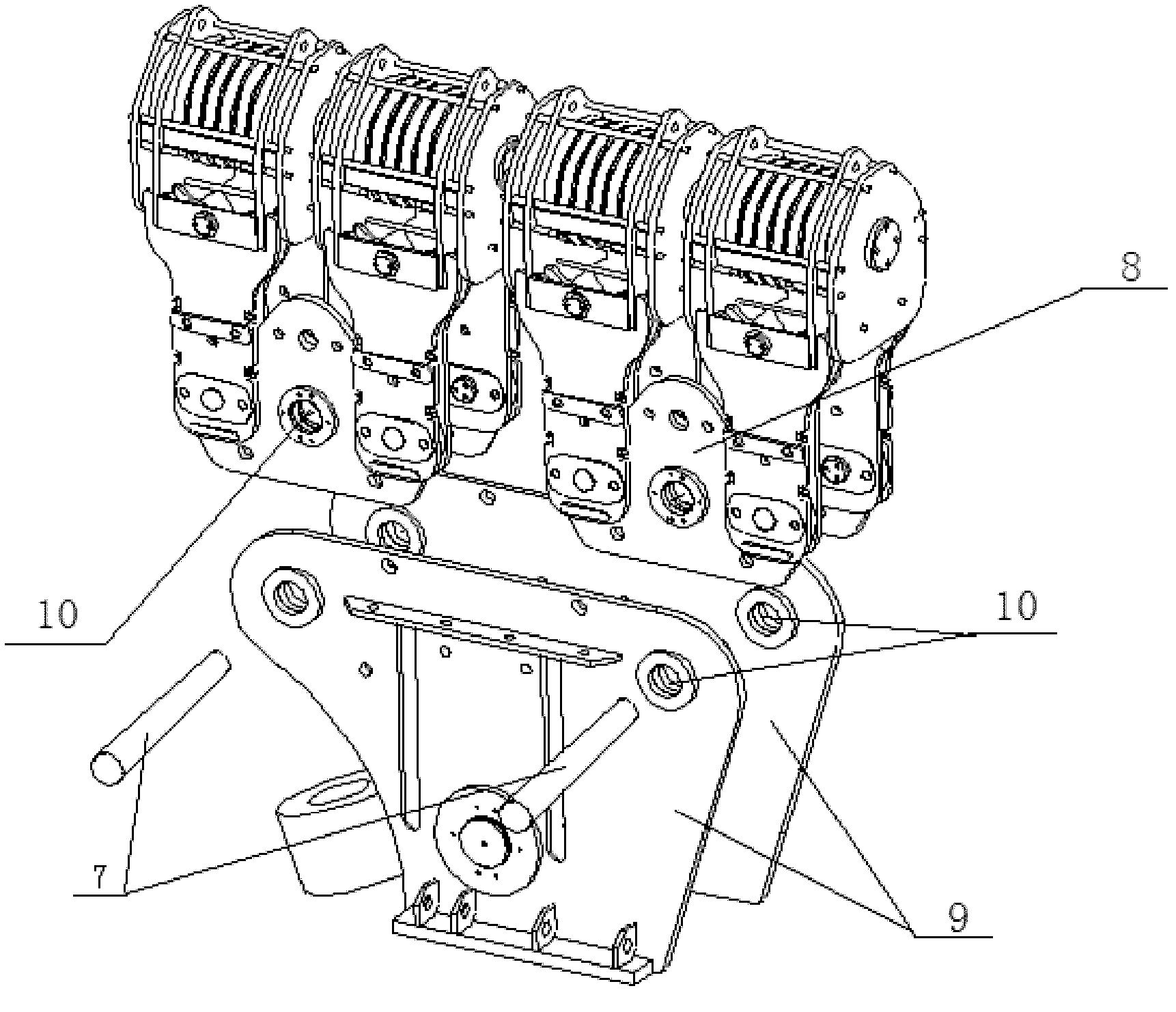

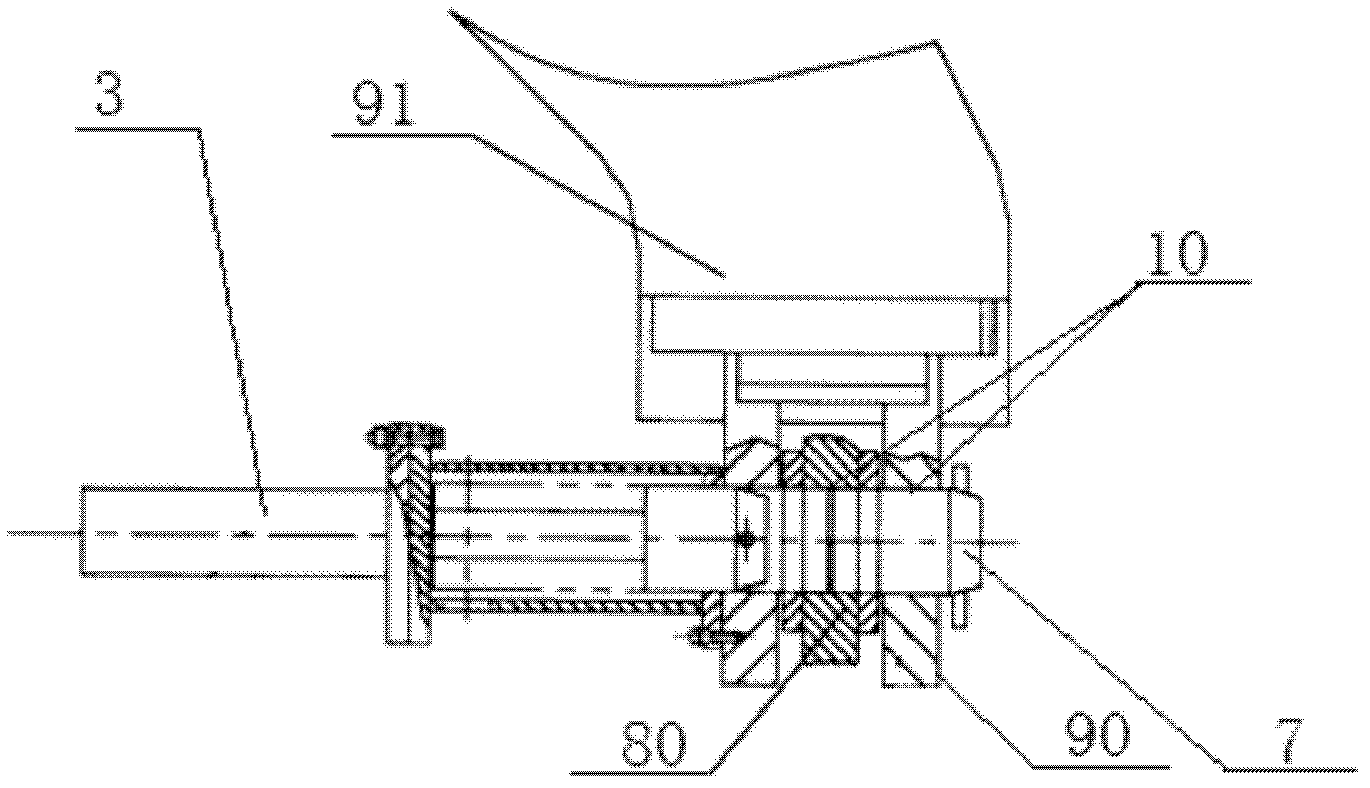

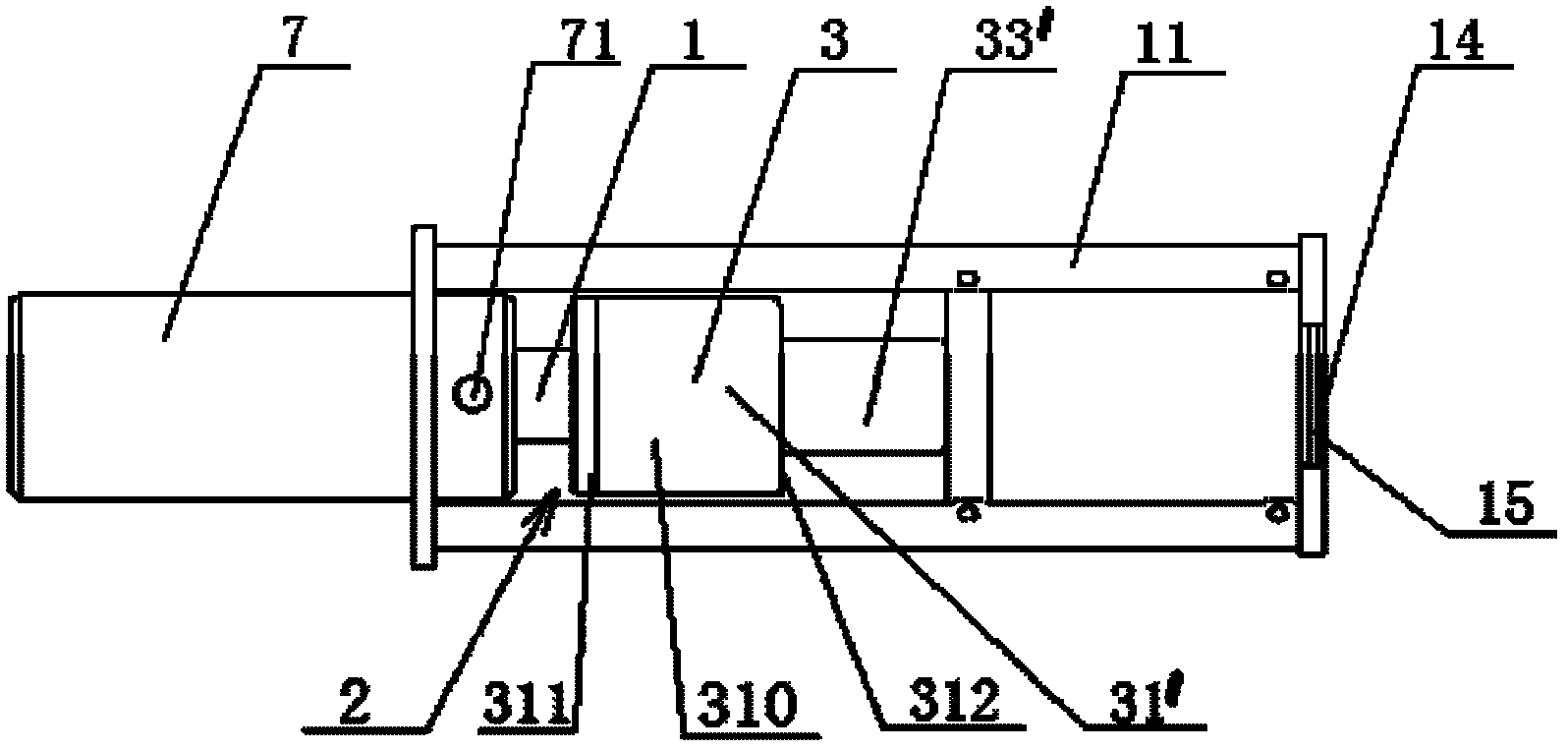

[0048] Such as image 3 , Figure 4 and Figure 5 As shown, the pin shaft moving device provided by the embodiment of the present invention includes a pin shaft 7, a rotary power device 2 and a transmission member 1 arranged in the rotary power device 2, wherein:

[0049] The pin shaft 7 is fixedly connected to the transmission part 1, or the pin shaft 7 and the transmission part 1 are in an integrated structure;

[0050] The rotating power device 2 is used to drive the transmission part 1 and the pin shaft 7 to rotate along the circumferential direction of the pin shaft 7, and simultaneously drive the transmission part 1 and the pin shaft 7 to advance or retreat along the axial direction of the pin shaft 7;

[0051] Both the pin shaft 7 and the transmission member 1 are coaxial (the axis refers to the rotation axis of the pin shaft 7 and the transmission member 1 ).

[0052] The axial direction refers to the direction extending along the axis of the pin shaft 7 and other c...

Embodiment 2

[0091] Such as Figure 8 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that in this embodiment, the circumferential power mechanism 22 also includes a guide chamber 33, but a third through hole 63 is opened on the guide chamber 33, and the guide chamber 33 is provided with a third through hole 63 for guiding The chamber 33 communicates with the power chamber 31 through the first through hole 61 opened in the first axial side wall 311;

[0092] The ball nut 41 is fixed on the inner wall of the first through hole 61 , and the transmission member 1 passes through the ball nut 41 and the third through hole 63 .

[0093] It can be seen from the above that the main difference between this embodiment and embodiment 1 is that the relative position of the guide chamber 33 and the transmission member 1 is different from that of embodiment 1, but the same as embodiment 1, this embodiment can also realize the above-mentioned invention The technica...

Embodiment 3

[0095] Such as Figure 9 As shown, this embodiment is basically the same as Embodiment 1, and the difference is that the circumferential power mechanism 22 in this embodiment includes a guide chamber 33 and an external thread 42 provided on the transmission member 1, wherein:

[0096] The guide chamber 33 communicates with the power chamber 31 through the second through hole 62 opened on the second axial side wall. The part of the transmission member 1 provided with the external thread 42 passes through the second through hole 62, and the outer thread 42 on the transmission part 1 passes through the second through hole 62, and the outer The thread 42 cooperates with the internal thread provided on the inner wall of the guide chamber 33 and / or the second through hole 62 .

[0097] Due to the helix angle of the thread, when one of the two parts connected by the thread moves linearly, it must rotate at the same time, so the external thread 42 on the transmission member 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com