Paver and floating baffle system used for same

A technology of paver and floating baffle, which is applied in the directions of roads, road repair, roads, etc., can solve the problems of the increase of mixtures, affecting the paving quality and increase of the pavement, and achieve the effect of improving the paving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

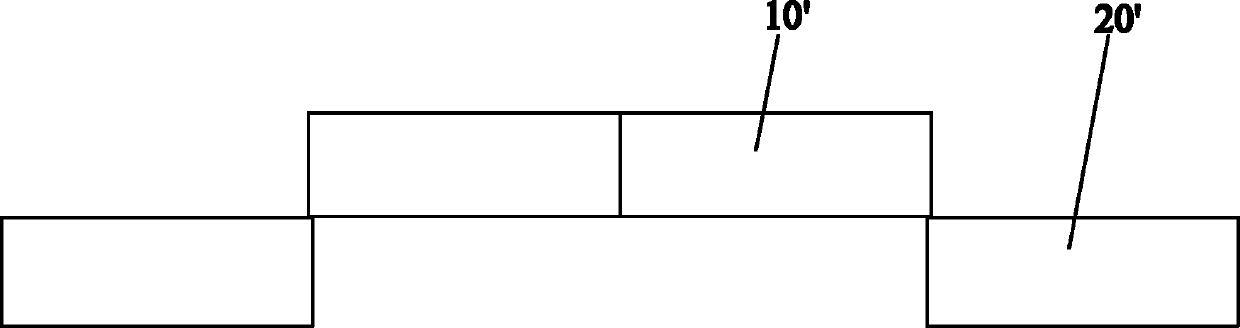

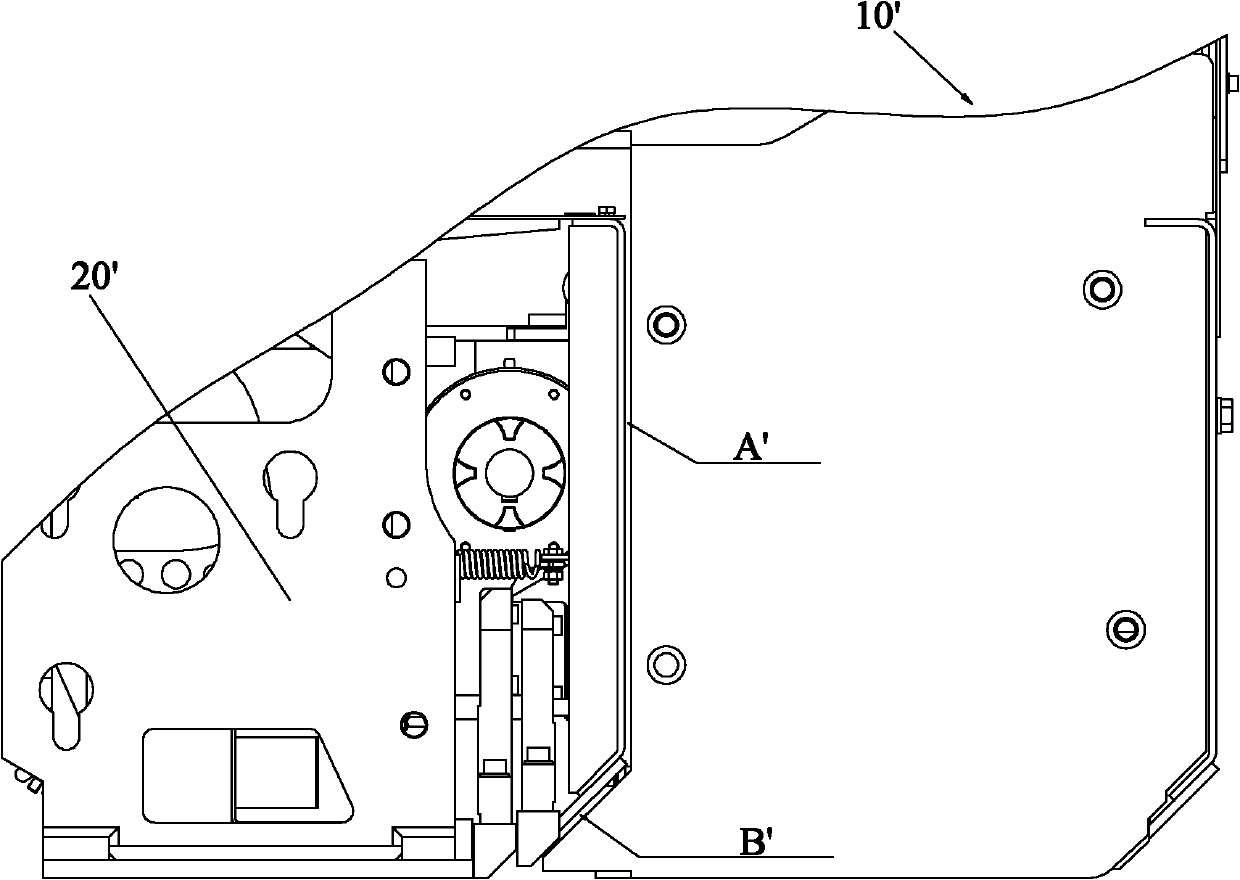

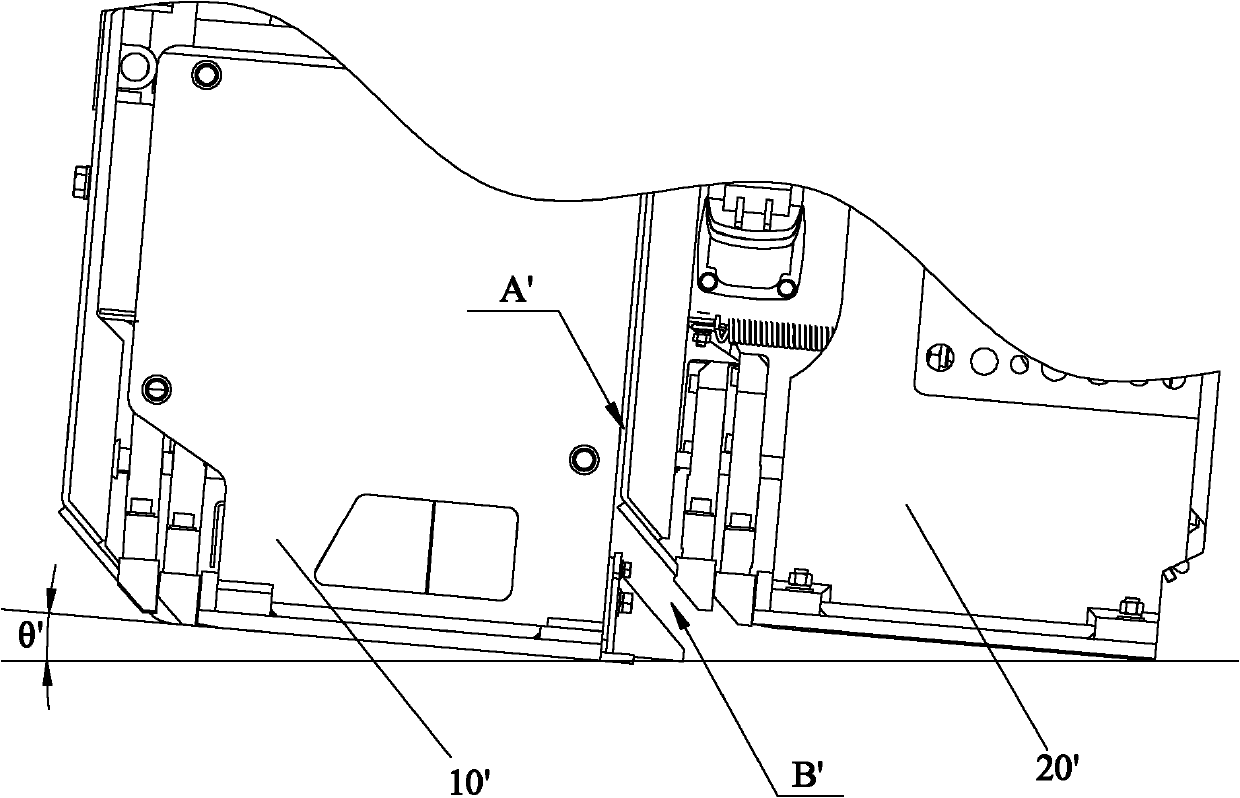

[0033] According to the floating stop system for paver of the present invention, the floating stop system fills the gap between the main screed 10 and the auxiliary screed 20, comprising: a fixed baffle 11 fixed on the main screed 10; The floating stopper device includes: a floating stopper 30, which is slidably arranged on the fixed stopper 11, and is located on one side of the auxiliary screed 20; plate 30, so that the floating baffle 30 is attached to the auxiliary screed 20.

[0034] Such as Figure 5 to Figure 7 as well as Figure 9 As shown, the fixed baffle 11 is fixed on the end plate 12 of the main screed on the side of the main screed 10 by countersunk head screws 14, and the floating baffle 30 is arranged on the fixed baffle 11, which is connected with the tamper of the auxiliary screed 20 The shape of the system front baffle contact matches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com