Lifting platform for protecting safety of high-level construction

A safety protection and lifting platform technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of high cost, a lot of labor, and low efficiency of folding lifting scaffolding, and achieve fast disassembly and assembly. The effect of saving costs and reducing the number of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

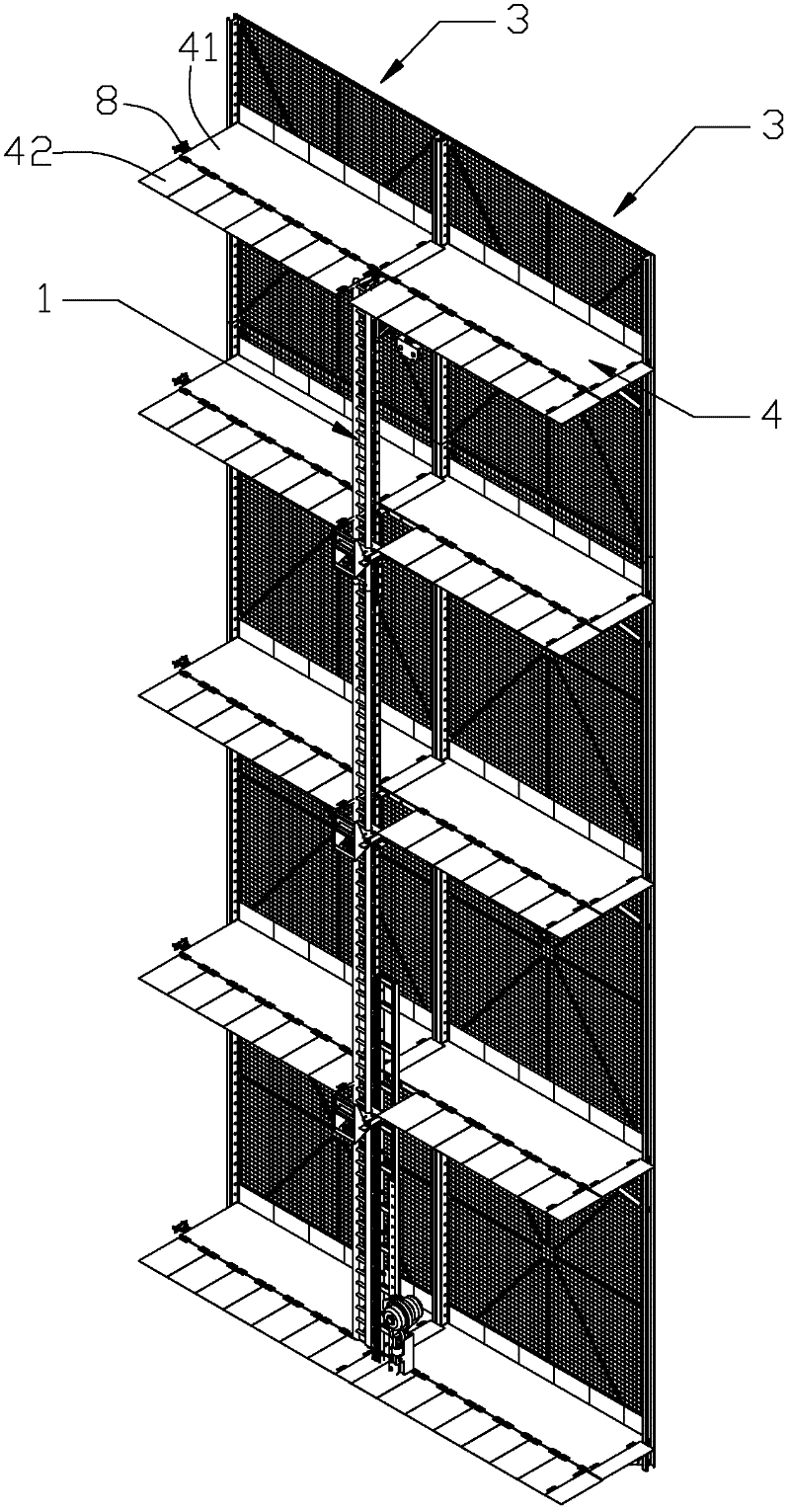

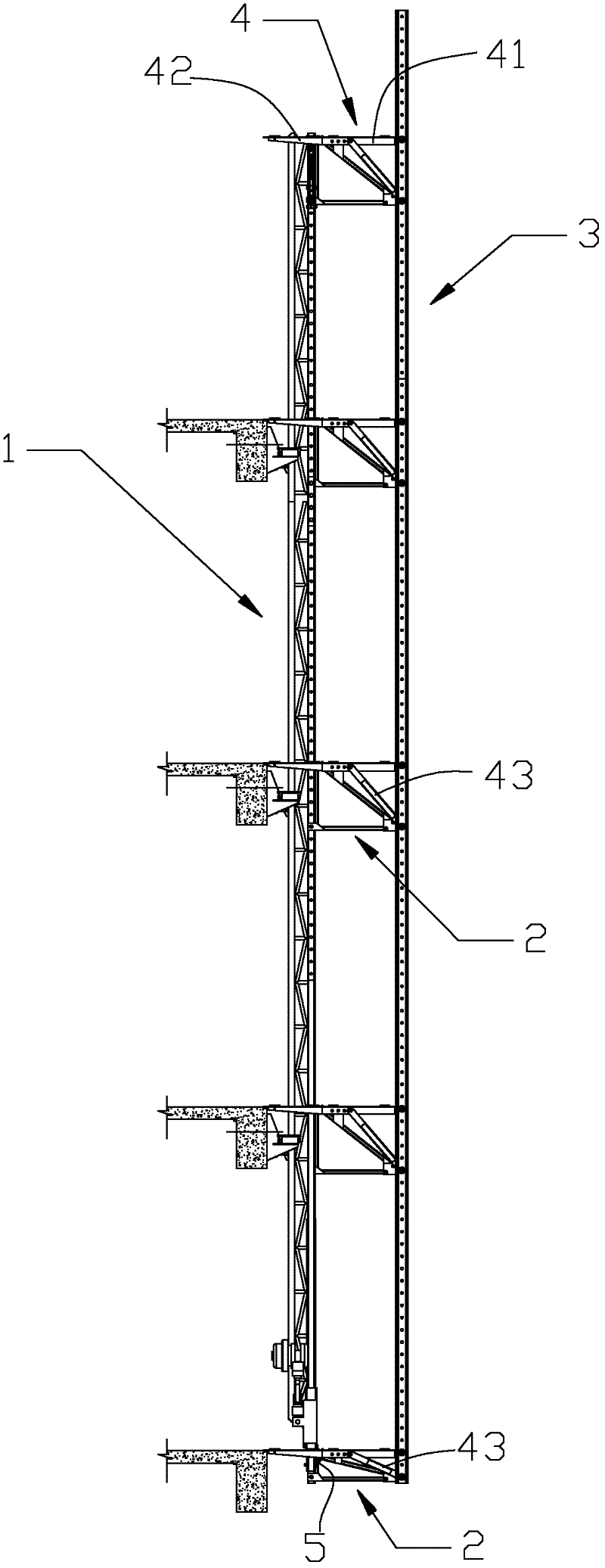

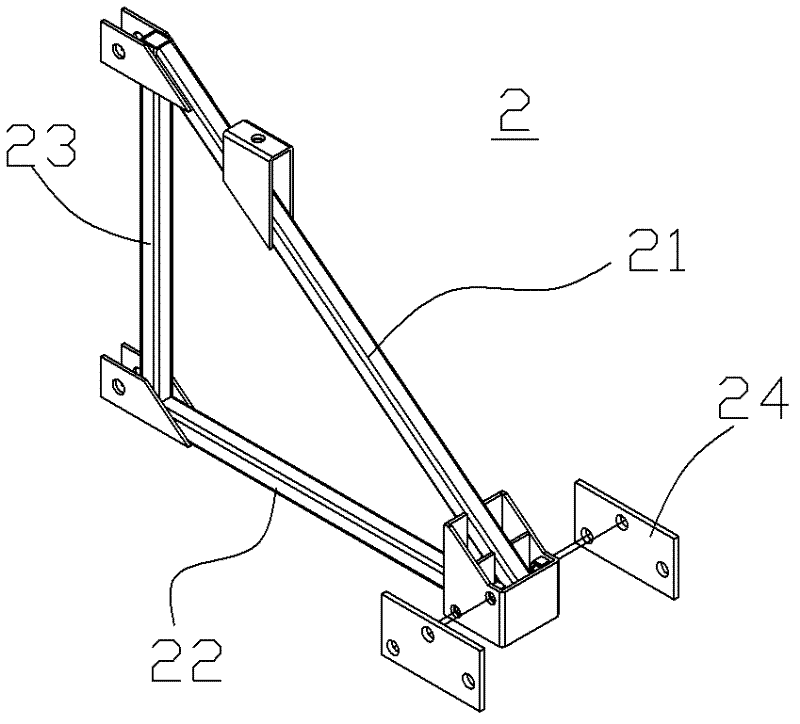

[0042] Such as figure 1 and figure 2 Shown is a schematic diagram of the first embodiment of the high-rise construction safety protection lifting platform of the present invention, the high-rise construction safety protection lifting platform includes an attached lifting scaffold stand system 1, see Figures 7a-7d, the attached elevating scaffold stand system 1 includes a force-bearing guide seat 11 and a vertical member 12 slidingly connected with the force-bearing guide seat 11 . Wherein, the load-bearing guide seat 11 is fixed on the periphery of the building. In an attached lifting scaffold stand system, a plurality of load-bearing guide seats 11 are included. These load-bearing guide seats 11 are arranged in a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com