Underground reservoir porosity measurement method during drilling

A measurement-while-drilling, porosity technology, applied in drilling measurement, drilling equipment, earth-moving drilling and production, etc., can solve the problems of complex operation and many influencing factors, achieve simple operation, wide adaptability, and meet the requirements of logging evaluation and storage. layer and the effect of discriminating reservoir fluid properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

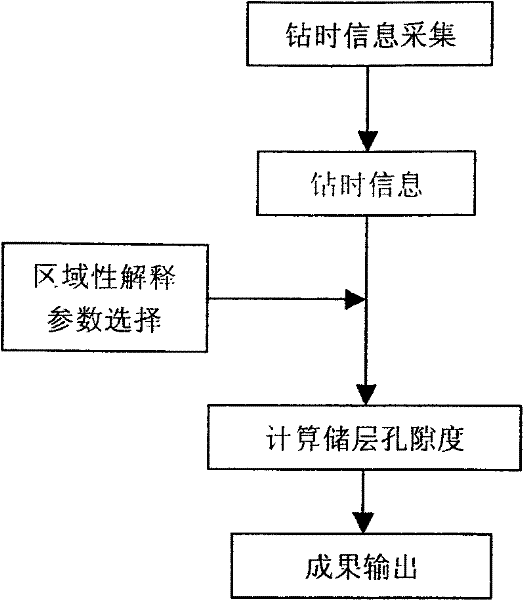

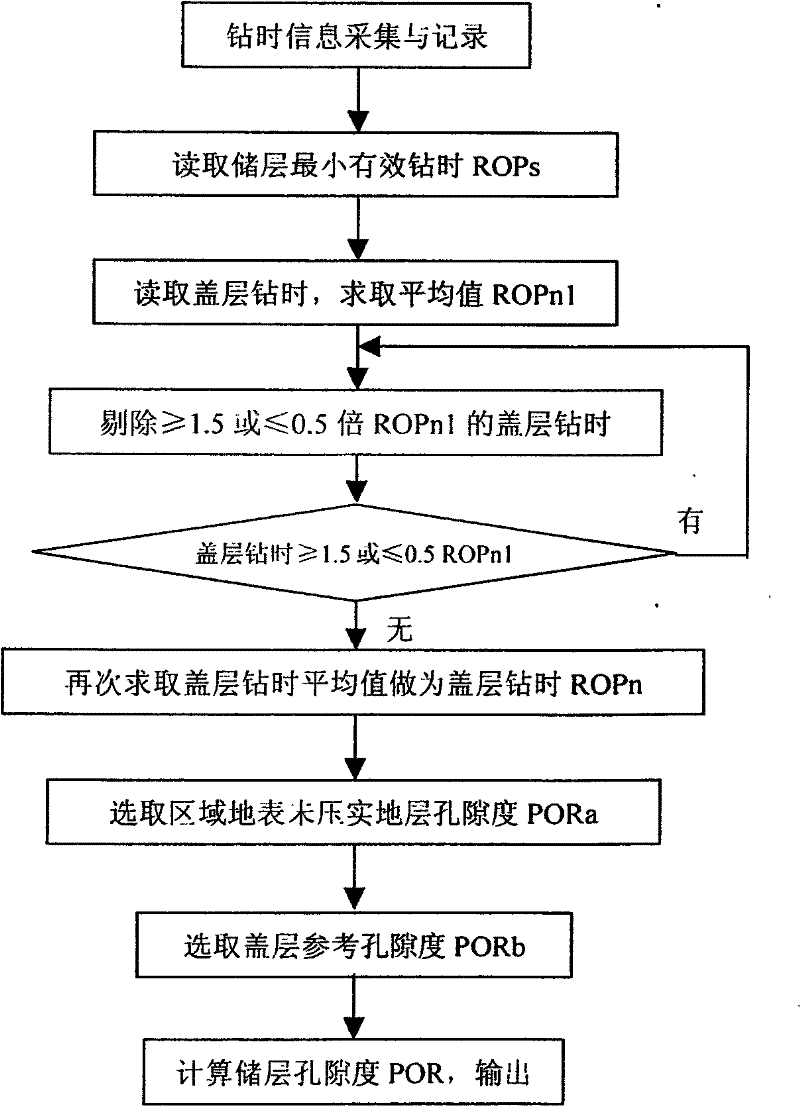

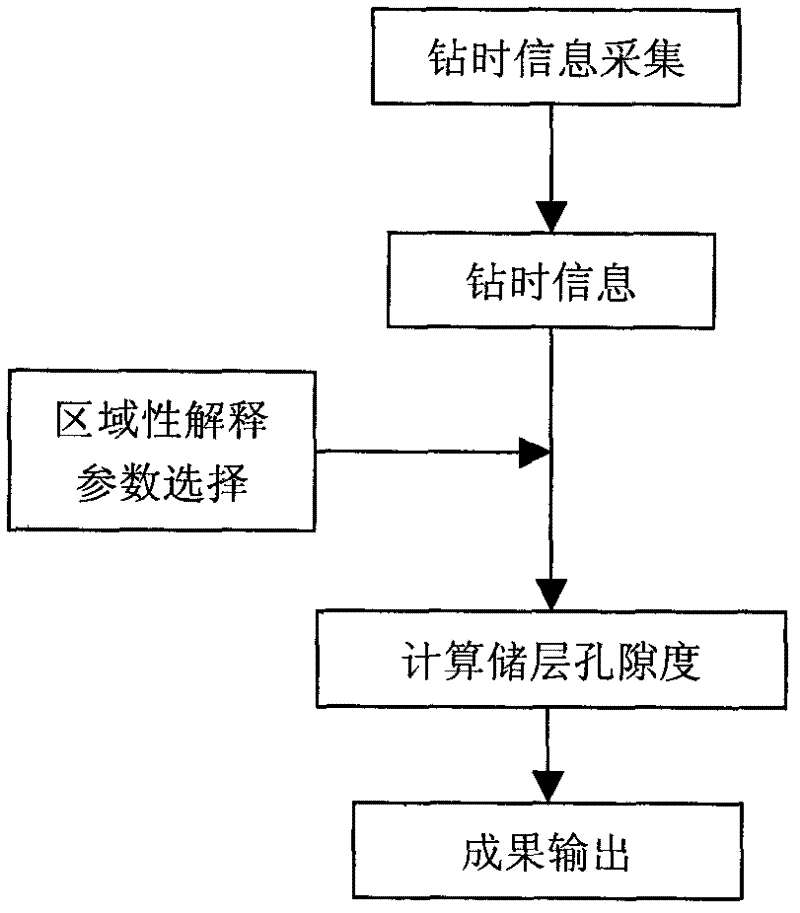

[0021] refer to figure 1 , the present invention utilizes mud logging devices such as comprehensive mud logging instrument, time-drilling instrument, gas measuring instrument, ROPs when drilling the reservoir measured while drilling and the average value ROPn when drilling the cap rock (non-reservoir) adjacent to the reservoir and The porosity PORa of the surface uncompacted formation with regional characteristics and the reference porosity PORb of the reservoir cap rock are calculated by POR=PORa-[(PORa-PORb)×LgROPs / LgROPn, and the real-time measurement while drilling is obtained. Reservoir porosity POR value. The POR value is also called gas porosity, which reflects the total porosity of the reservoir.

[0022] Time-drilling instrument, gas measuring instrument, comprehensive mud logging instrument, drilling instrument and other mud logging devices adopt existing drilling and mud logging equipment. Acquisition and recording During mud logging drilling, it is the time taken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com