Coal mine underground airbridge construction method

A construction method and wind bridge technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve problems such as low efficiency, large amount of engineering, long construction period, etc., and achieve high safety factor, low cost, The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

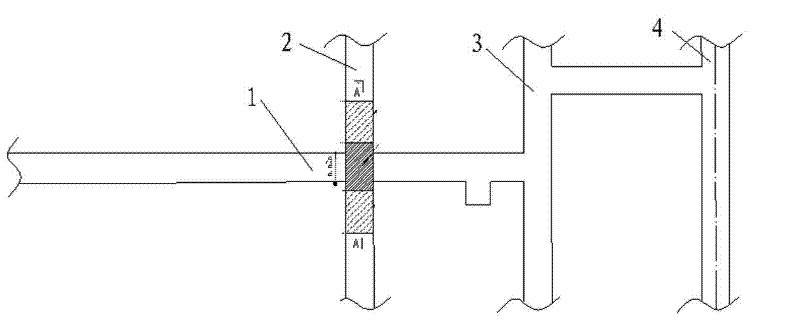

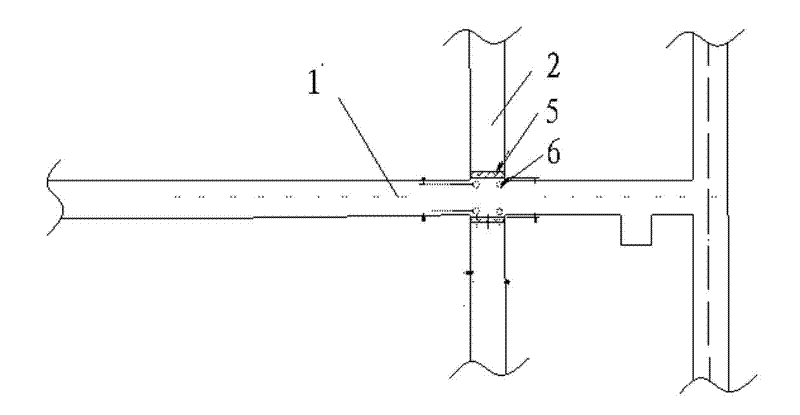

[0019] Such as figure 1 As shown, the construction method of the wind bridge under the coal mine, the return air roadway 2 is directly excavated along the coal seam roof by machine excavation and intersects with the horizontal roadway 1, and then it is excavated forward to the inspection and maintenance of Hengchuan to form the entire roadway system, roadway 1 and return air The intersection of roadway 2 is the wind bridge section, and then the wind bridge section is formed by blasting the roof and masonry.

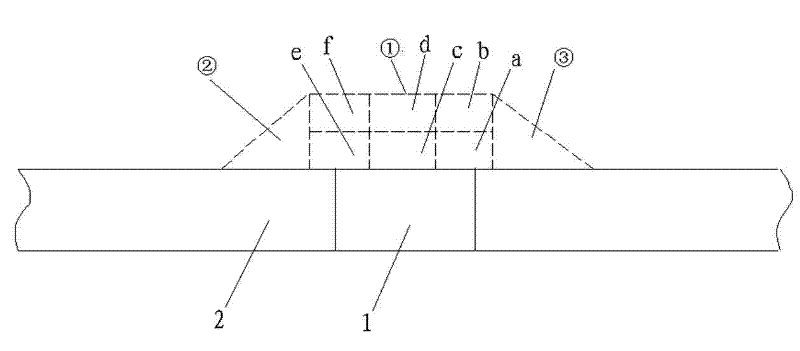

[0020] The wind bridge formed by the construction of the present invention has a rectangular section with a gross section of 12.22㎡ and a net section of 11.25㎡. The roadway is jointly supported by bolts, metal mesh and metal belts and reinforced by anchor cables.

[0021] The top and side of the roadway are all made of Φ18mm, 2.0m long metal rod body of rebar type resin anchor without longitudinal ribs, model: MSGLW-400; the top anchor uses one MSK2335 resin coil and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com