Variable air valve lift mechanism of internal combustion engine

A technology of valve lift and valve mechanism, which is applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problem that the valve lift cannot be accurately controlled, the plunger rotation angle is not easy to accurately determine, and the exact moment of the oil level cannot be quickly determined. Good determination and other issues, to achieve the effect of improving power and fuel economy, facilitating miniaturization, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

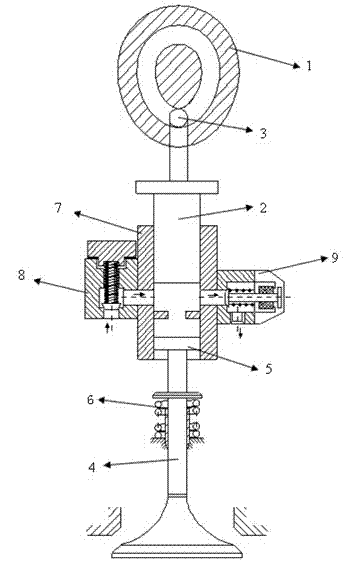

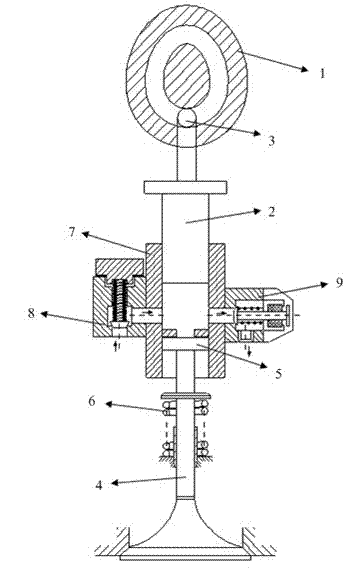

[0028] Such as figure 1 , figure 2 and Figure 4 As shown, the internal combustion engine variable valve lift mechanism provided in this embodiment includes a driving mechanism, a plunger pin 3, a hydraulic mechanism, a control valve and a valve mechanism, wherein the driving mechanism is connected with the hydraulic mechanism through the plunger pin 3, and the hydraulic mechanism The mechanism is connected with the valve mechanism, and the control valve is arranged on the hydraulic mechanism. The driving mechanism includes a grooved cam 1, which is connected to the hydraulic mechanism through a plunger pin 3; the hydraulic mechanism includes a hydraulic plunger 2 and a hydraulic cylinder 7, wherein the hydraulic plunger 2 is movably installed in the hydraulic cylinder 7 and is closely attached to the hydraulic cylinder One end of the plunger pin 3 is connected with the groove cam 1, and the other end of the plunger pin 3 is connected with the hydraulic plunger 2; the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com