High-pressure automatic gas drainage device

A drainer and automatic technology, which is applied in gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problems of difficult installation, bloated, enlarged equipment, etc., to reduce production costs, reduce labor intensity, and reduce infrastructure The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

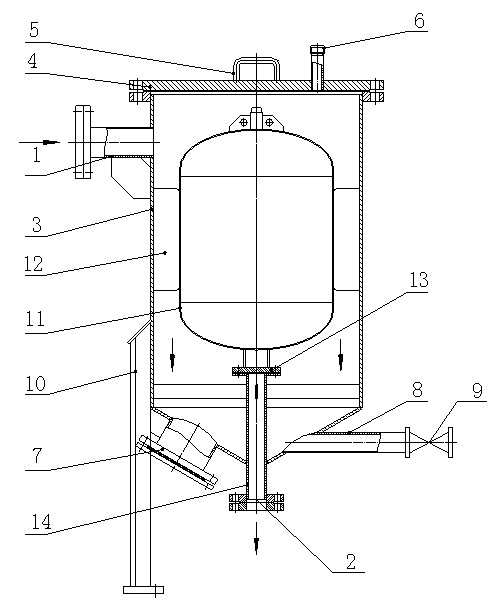

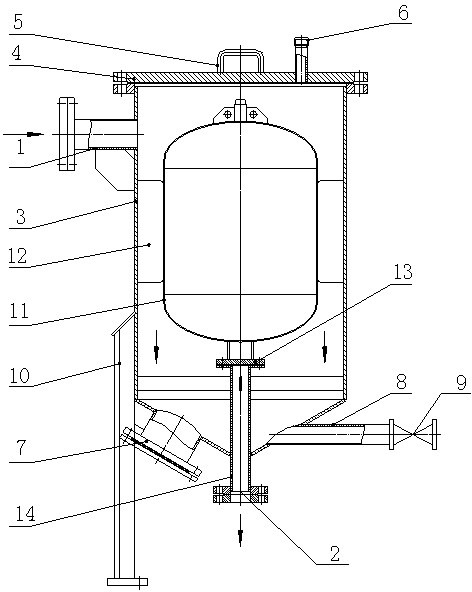

[0016] like figure 1 As shown, the high-pressure automatic gas drainer of the present invention includes a housing 3 with a water inlet 1 and a water outlet 2, the water inlet 1 is located on one side of the housing 3, the water outlet 2 is located at the bottom of the housing 3, and the housing The top of the body 3 is provided with a top cover 4, the top cover 4 is provided with a handle 5 and an exhaust port 6, one side of the bottom of the housing 3 is provided with a hand hole 7, and the other side of the bottom of the housing 3 is connected by a sewage pipe 8 There is a sewage outlet 9, the outside of the shell 3 is provided with a leg 10, the shell 3 is provided with a buoy 11, the two sides of the buoy 11 are provided with a buoy positioning device 12, and the buoy positioning device 12 is fixed on the side wall of the shell 3, The bottom of the buoy 11 is provided with a sealing device 13, the sealing device 13 is a sealing ring, and a drainage pipe 14 is provided dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com