Unreeling device in copper tube

A technology of internal wire laying and copper pipes, which is applied in the field of cables, can solve the problems of not being able to adapt well to new process requirements, the large footprint of the wire discharging device, and the reduction of the quality of coaxial cables, etc., to achieve a small footprint, High disk changing efficiency, maintaining shape and roundness

Active Publication Date: 2013-07-03

JIANGSU TRIGIANT TECH

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

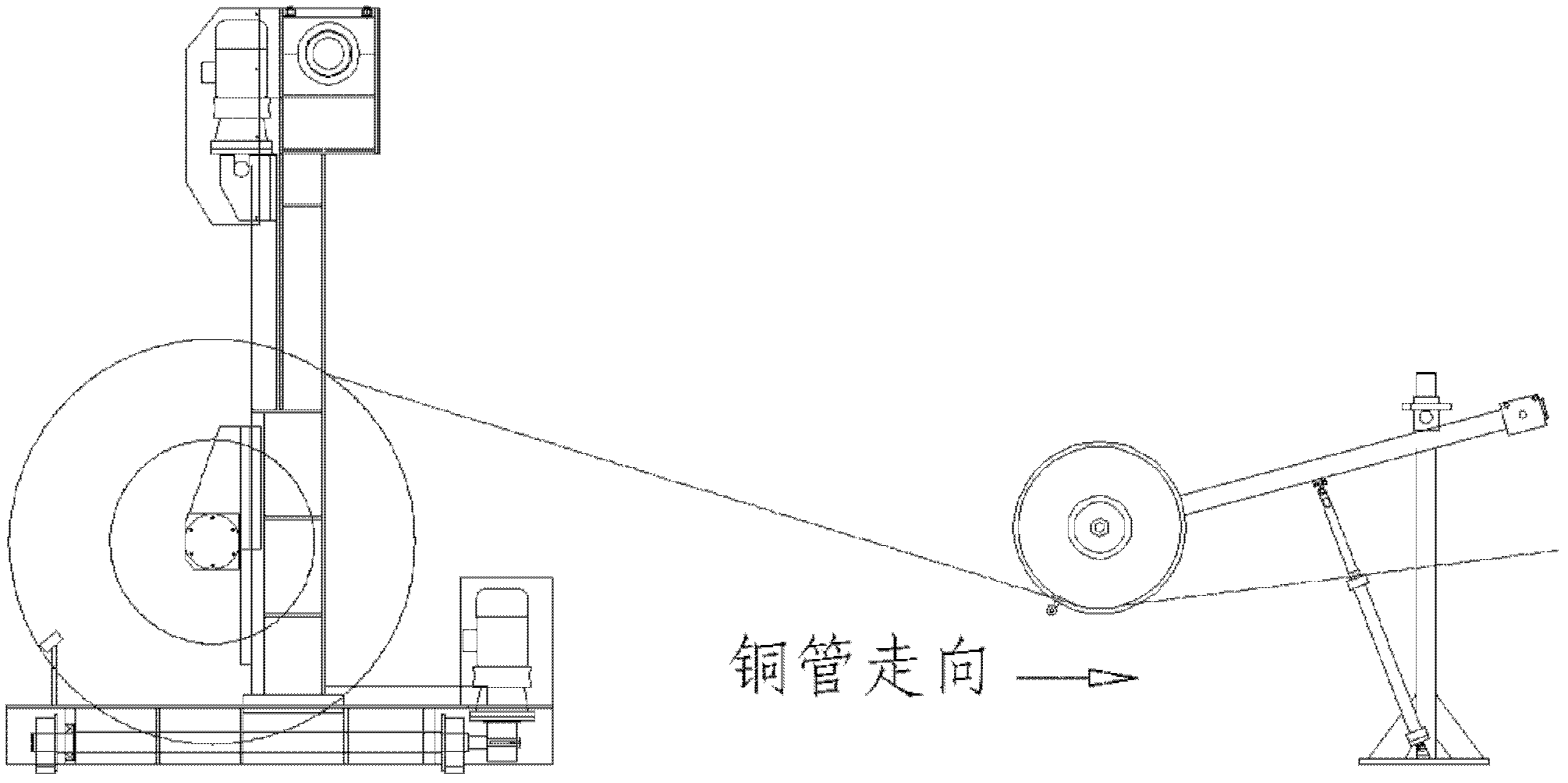

In actual use, such as figure 1 , the existing pay-off device has several disadvantages: one is that the entire pay-off device occupies a larger area; The increase of disk change time will affect the production efficiency; the third is that the cost of equipment is high, in order to ensure the uniformity of tension, it is necessary to use active pay-off racks, which work together with movable ground rails, position sensors, and tension dance wheels; four is , with the increasing shortage of copper resources and the rising international copper prices, the thickness of the existing copper tubes is getting thinner and thinner. Problems such as copper tube bending, flattening, scratching, and poor wiring are becoming more and more serious, which greatly reduces the quality of coaxial cables

[0003] To sum up, the existing copper tube pay-off device can no longer adapt to the new process requirements, and the production efficiency is low and the transportation cost is high, so there is still room for improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Login to View More

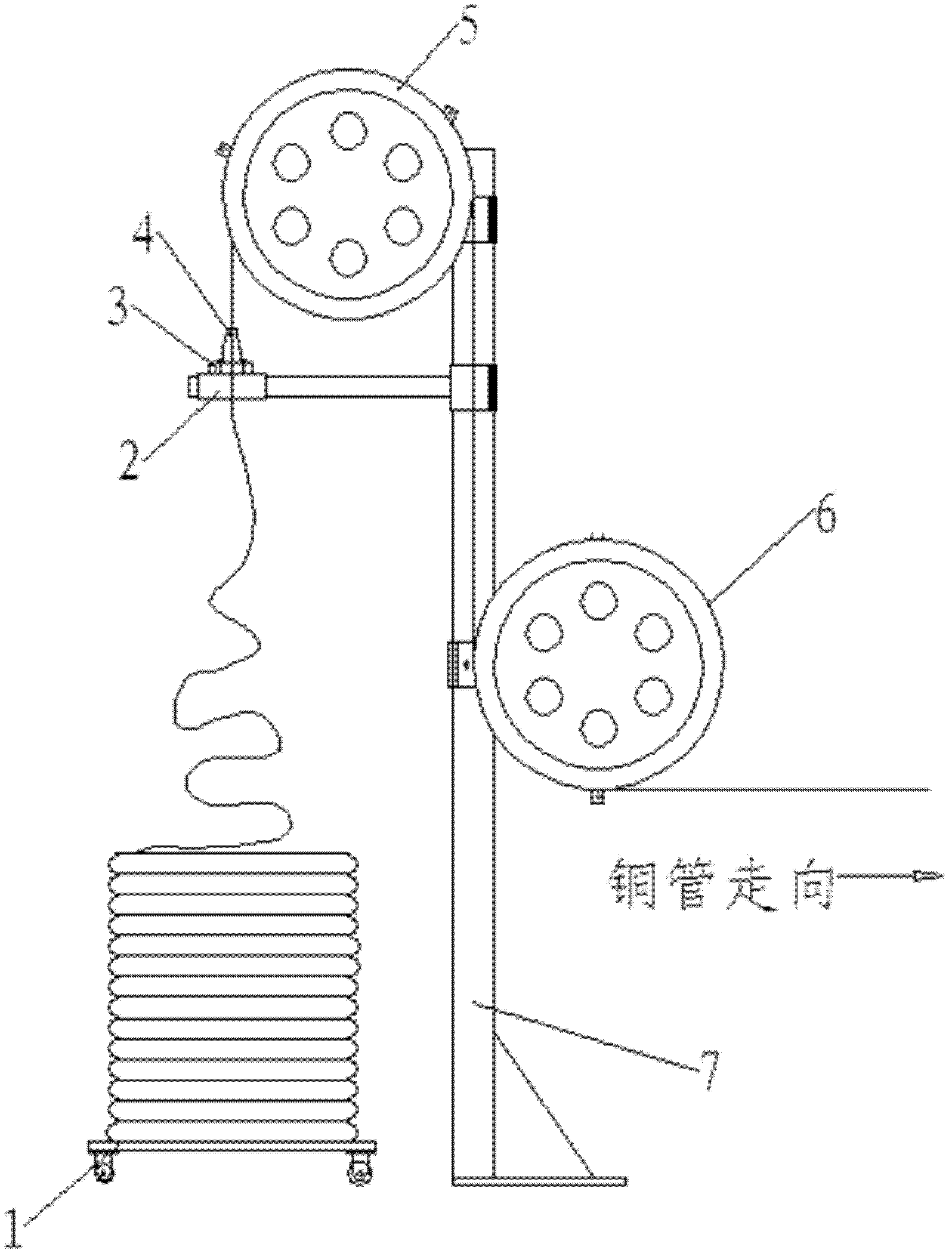

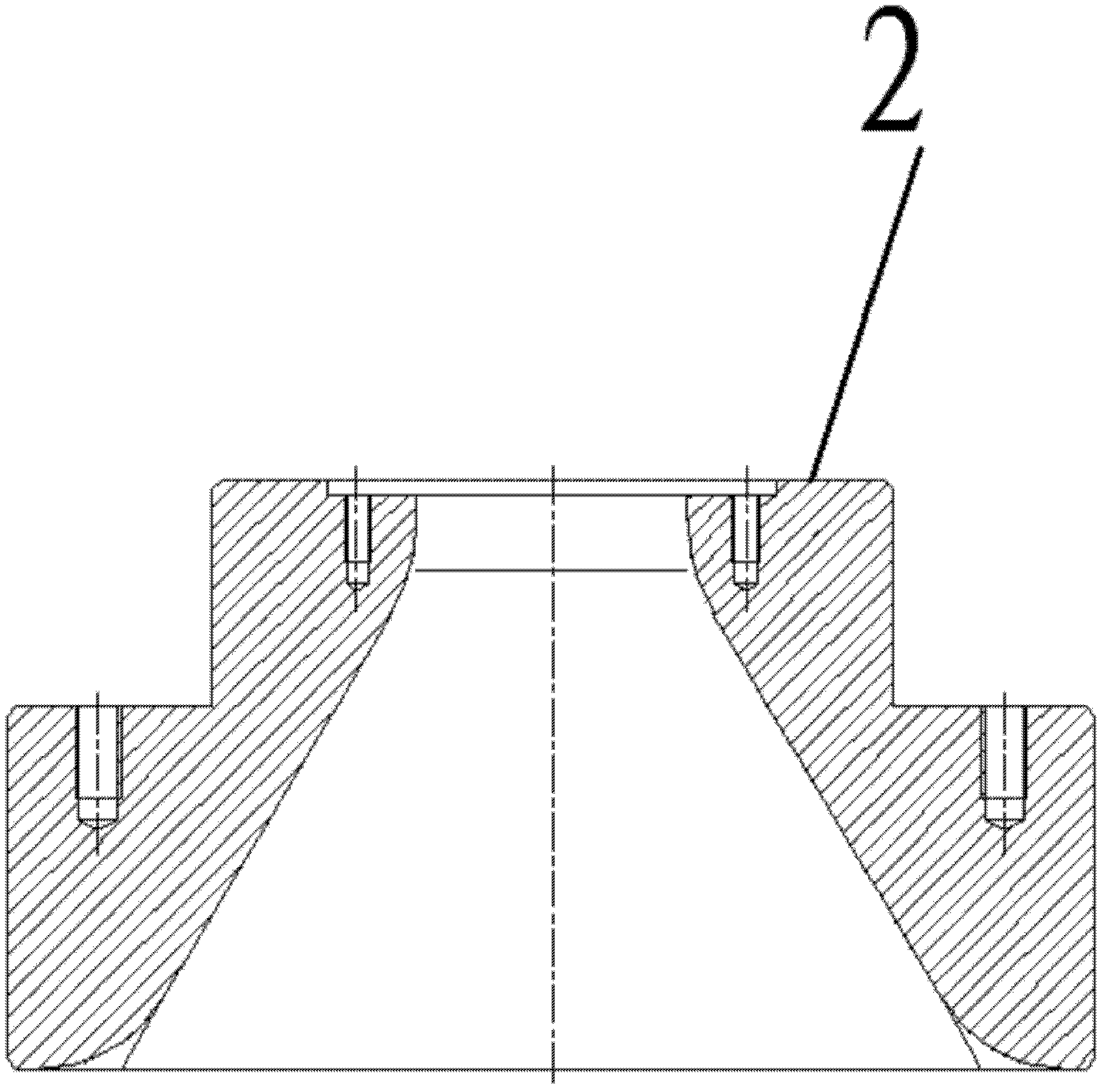

Abstract

The utility model relates to an unreeling device in a copper tube, which comprises a bottom wheel supporting rack (1), a horn mould (2), a connecting plate (3), a wire passing mould (4), an upper guide wheel (5), a lower guide wheel (6) and a base (7). The connecting plate (3) is disposed between the horn mould (2) and the wire passing mould (4). A flange guide structure on the head in the coppertube is employed in the unreeling device, so that floor area is reduced, and two wire plates can be placed at the same time; and a connector can be made in advance, so that a break will not be causedin the process of replacing the wire plates, and continuous production is ensured, thereby improving working efficiency of the whole production line. The unreeling device is simple in manufacturing process, low in cost, high in production efficiency and more reliable in quality of product.

Description

technical field [0001] The invention relates to the field of cables, in particular to a copper tube internal pay-off device for coaxial cables. Background technique [0002] In the field of communication transmission, coaxial cable, as an important signal transmission medium, can be widely used in communication signal transmission fields such as base station feeders, communication equipment connecting lines and indoor distribution. The existing coaxial cable inner conductor pay-off device includes three parts: vertical gantry pay-off frame, position sensor and tension dancer. In actual use, such as figure 1 , the existing pay-off device has several shortcomings: first, the entire pay-off device occupies a large area; second, it is inconvenient to change the reel, that is, only one reel can be placed at a time. The increase in the time of changing the disk will affect the production efficiency. Third, the equipment cost is high. In order to ensure the uniformity of the tens...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01B13/016

Inventor 张爱军吴健真姚文讯冯玲芳

Owner JIANGSU TRIGIANT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com