Assembly process for IGBT (insulated gate bipolar transistor)

A process and station technology, applied in the field of IGBT assembly process, can solve the problems of products not reaching the professional level, affecting product quality, and damage to the surface of components, so as to save time in finding materials and tools, improve On-site management level and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

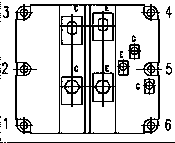

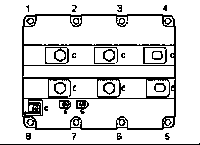

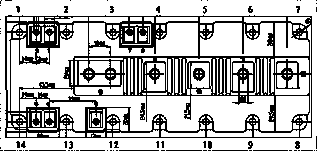

[0030] Such as Figures 1 to 5 It shows a specific embodiment of an IGBT assembly process flow of the present invention: an IGBT assembly process flow, 6 station points are set during the assembly process, and work stations are respectively set at each corresponding station point. Appliance area, and set up an inspector, including the following process steps:

[0031] (1) Set station 1 and apply insulating silicone grease;

[0032] ① Buckle the IGBT upside down on the special fixed tooling bracket, and pay attention to prevent collision, friction, etc.;

[0033] ② Before applying insulating silicone grease, use a clean cotton cloth or use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com