Compact type secondary connector

A connector, compact technology, applied in the field of electronics, can solve the problems of unsuitability for small-volume equipment, low reliability, unsuitability, etc., to meet the needs of small size and reliability, enhance reliability, and save space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

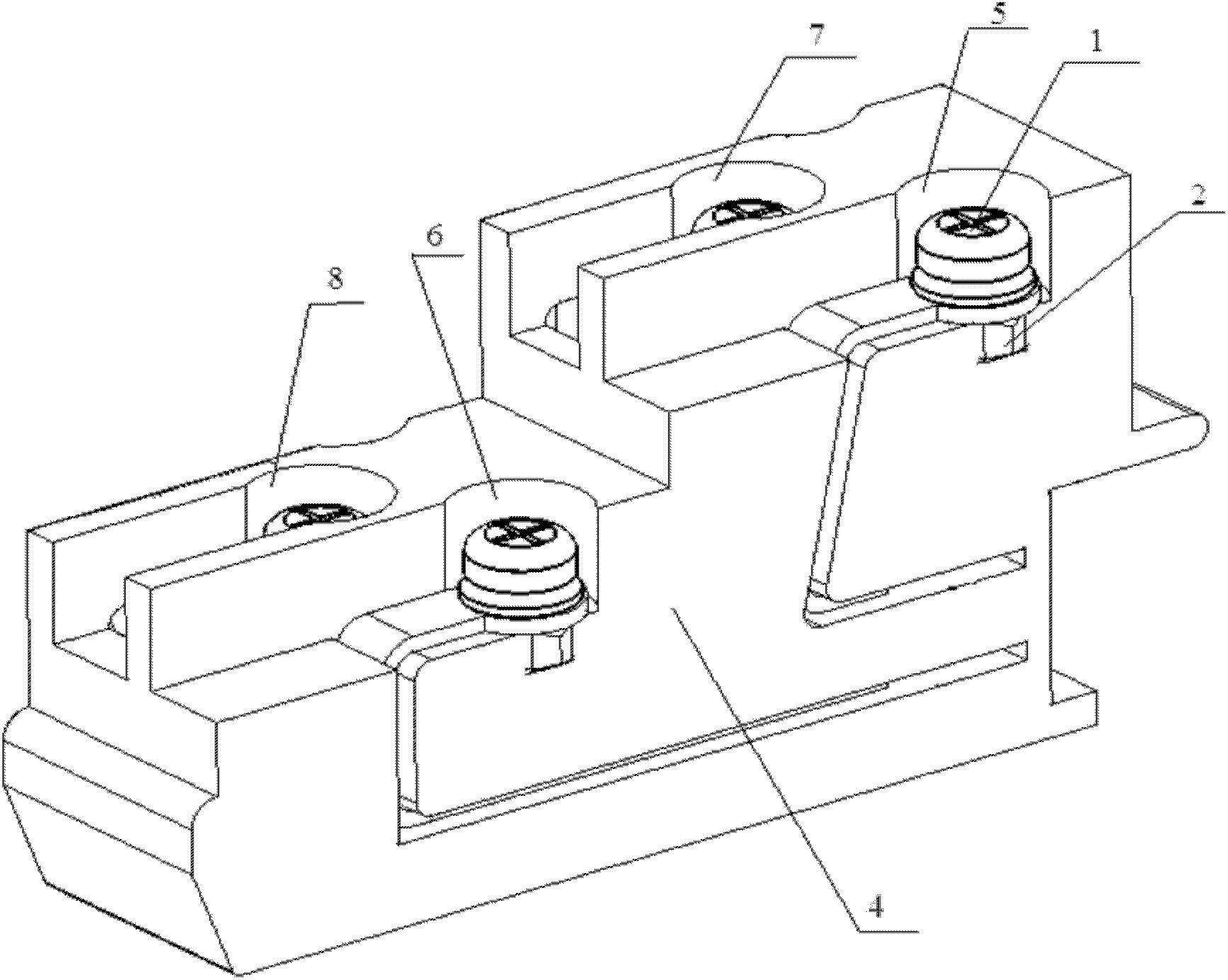

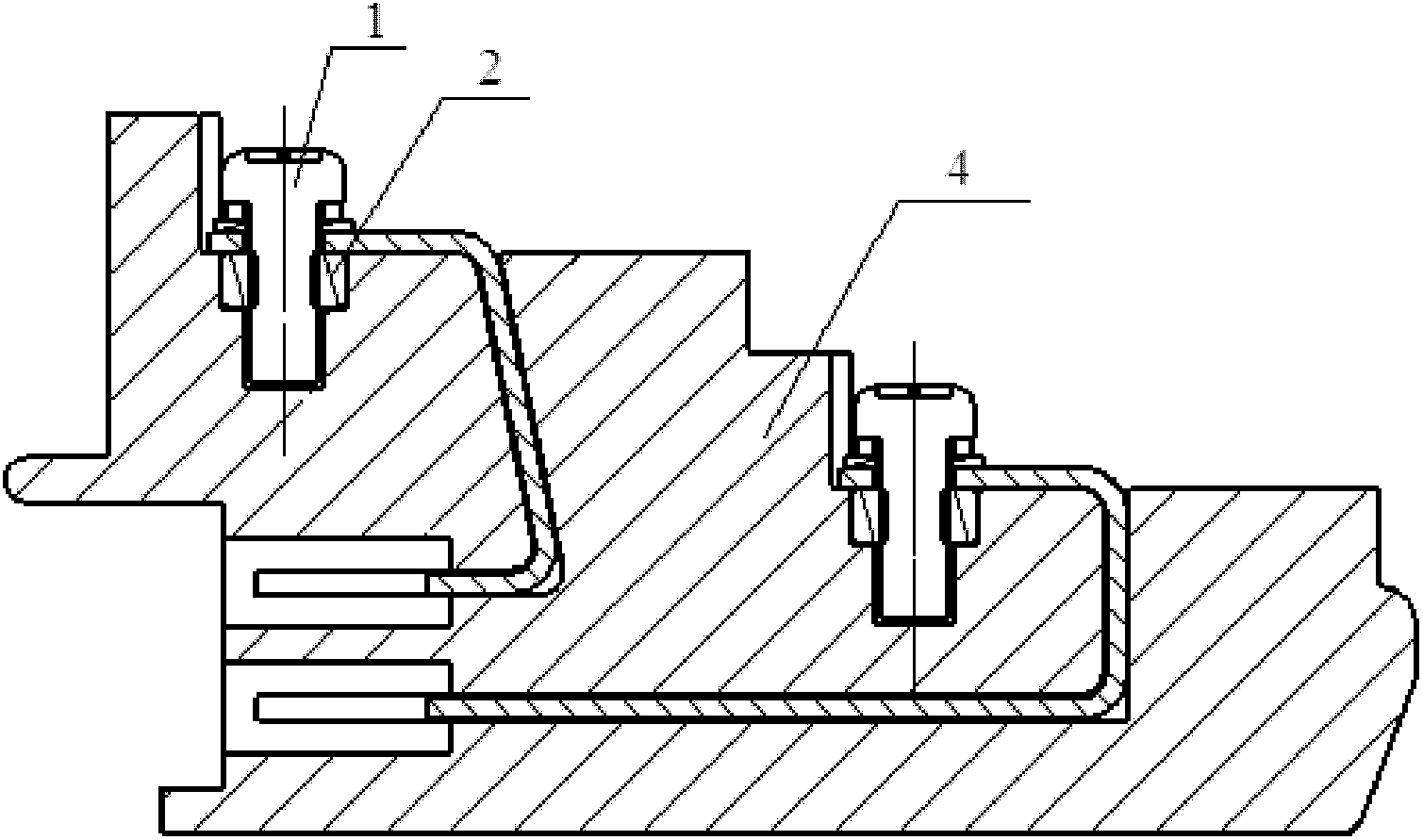

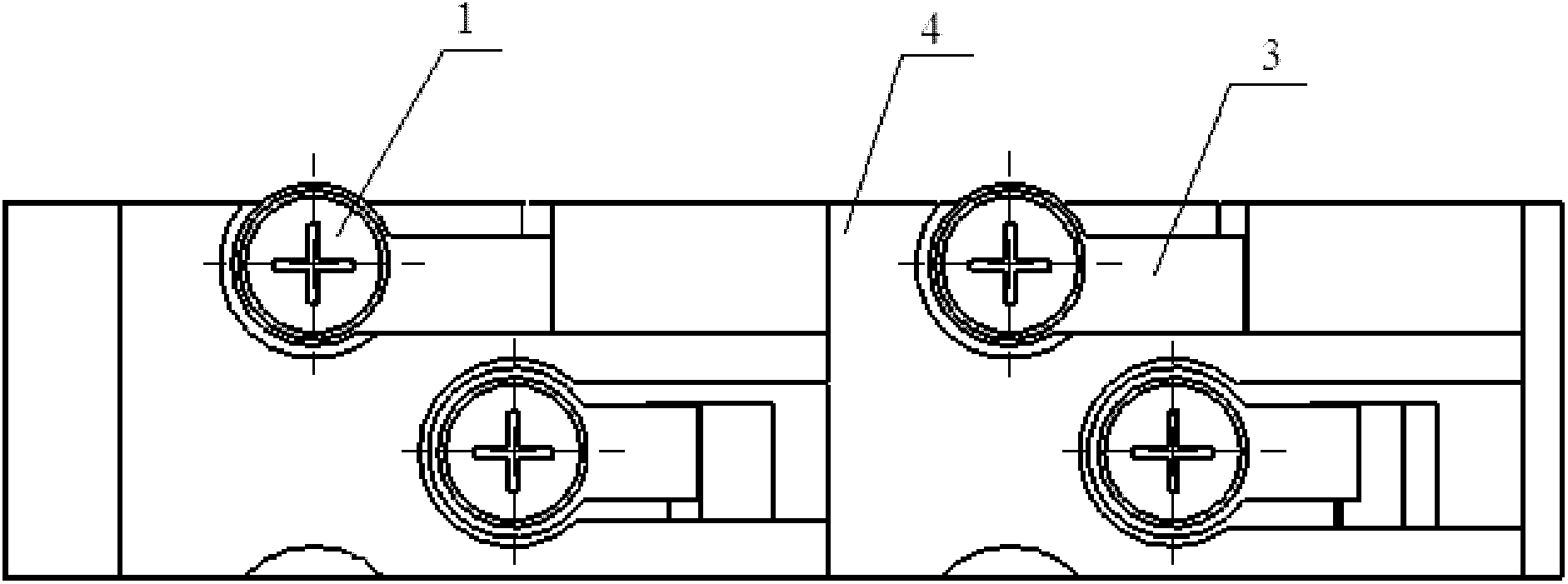

[0019] Such as figure 1 A compact secondary connector shown includes a base 4 , lugs, screws 1 and hex nuts 2 . The base 4 is a double-layer stepped structure, the upper surface is processed with installation grooves A5 and C7, and the lower surface is processed with installation grooves B6 and D8.

[0020] The installation groove C7 and the installation groove D8 are on the same straight line and have the same size. They are all connected by a circular groove and a square groove. The width of the square groove is smaller than the diameter of the circular groove. The installation groove A5 and the installation groove B6 are on the same straight line and have the same size. They are both connected by a circular groove with a notch along the end face of the base and an L-shaped groove. The width of the L-shaped groove is smaller than the diameter of the not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com