Method and apparatus for the automated manufacture of different toric optical lenses

A technology of toric lens and optical lens, which is applied in the field of automatic manufacturing of different toric optical lenses, can solve the problems of production interruption and high cost, and achieve the effect of reducing cost, reducing cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

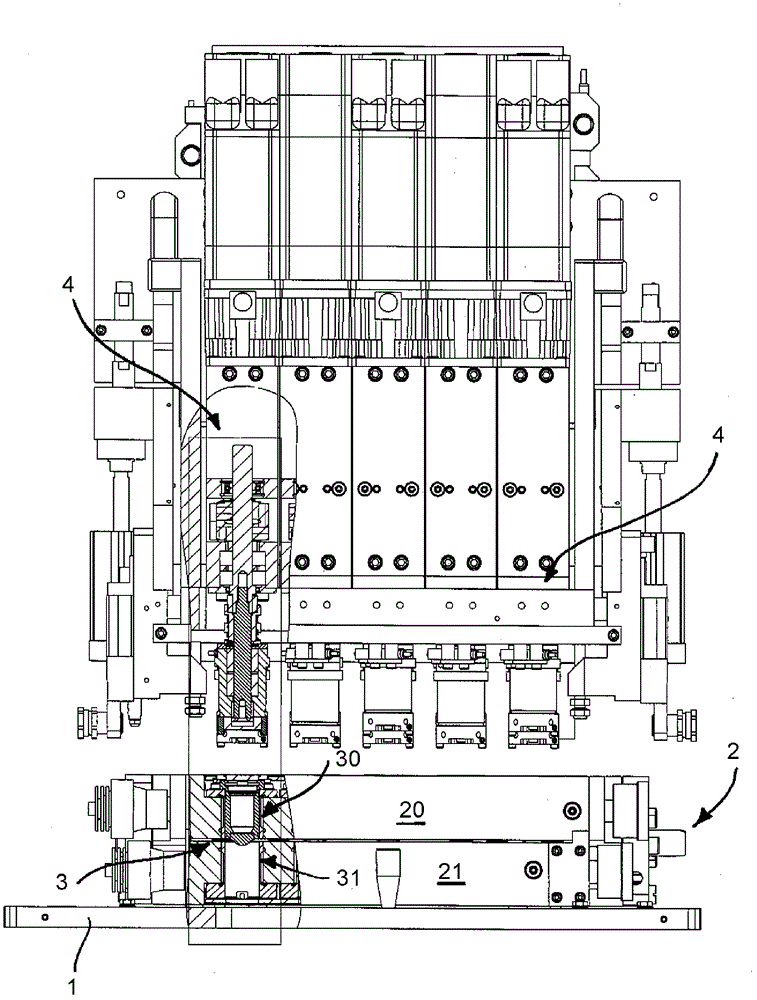

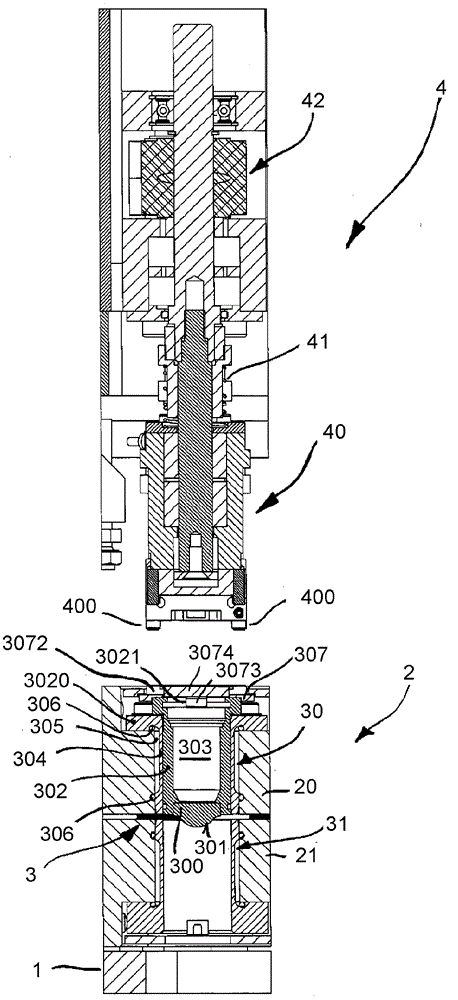

[0036] exist figure 1 In , a detailed view of a production line comprising an embodiment of the apparatus of the present invention is shown. On the support 1 is shown a formwork 2 comprising a first formwork member 20 and a second formwork member 21 carrying a plurality of male halves releasably clamped therein. mold 30, the second mold frame member 21 carries a plurality of corresponding female mold halves 31 releasably clamped therein. The first and second frame members 20 and 21 are pivotally connected to each other. Here the formwork 2 and the mold 3 comprising the male mold half 30 and the female mold half 31 are shown in their closed state. Although in the illustrated embodiment the formwork 2 comprises a total of ten molds 3 arranged in two rows and five columns, only one male mold half 30 representing one mold 3 is shown for the sake of simplicity of the drawing.

[0037] Ten rotating units 4 are arranged above the formwork 2, and figure 1 Only five of them are vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com