A kind of imitation embroidery three-dimensional pattern home textile fabric and its manufacturing method

A technology of three-dimensional pattern and manufacturing method, applied in the field of textile fabrics, can solve the problem of high price, save time, enrich varieties, and meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

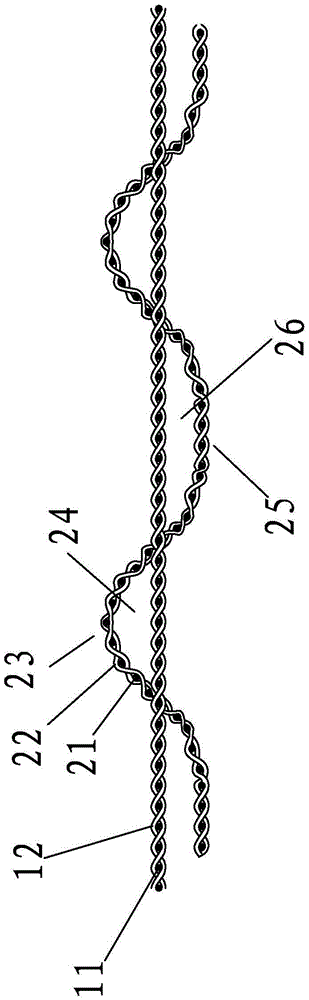

[0020] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

[0021] refer to figure 1 , a home textile fabric with three-dimensional patterns imitating embroidery, comprising interwoven interior warp and weft yarns and surface warp and weft yarns, the interior warp and weft yarns comprising interwoven interior warp yarns 11 and interior weft yarns 12, and the surface warp and weft yarns comprising interwoven surface warp yarns 21 and surface warp yarns Weft 22. The part where the surface warp and weft yarns are located on the upper surface of the inner warp and weft yarns is formed with first colored reliefs 23, and the first cavity 24 is formed between the first colored reliefs 23 and the corresponding inner warp and weft yarns. The part of the yarn located on the lower surface of the inner warp and weft yarns is formed with a second colored convex pattern 25, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com