A Coal Blending Method for Start-up of 7.5m Coke Oven

A technology for coke oven and coal blending, which is applied in the field of coal blending of 7.5m coke ovens, can solve problems such as furnace wall damage, and achieve the effect of avoiding excessive expansion pressure and satisfying coke quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

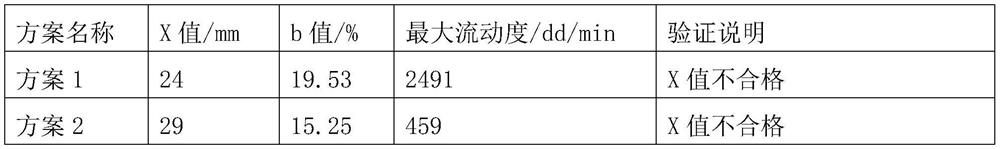

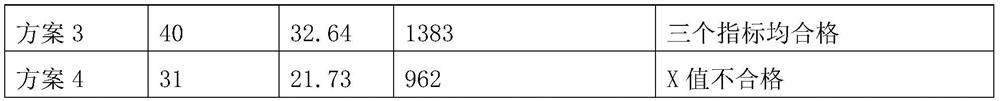

[0042] (1) According to the statistics of coal quality data with good coking performance and stable coke pushing current in the 6-meter coke oven in the past six months, the fluctuation range of X value is between 28 and 36mm, and the range of maximum fluidity is between 50 and 1100dd / min The fluctuation range of b value is between 10% and 36%.

[0043] (2) Calculation of shrinkage, expansion and maximum fluidity of 7.5m coke oven blend coal:

[0044] ①The lower limit value of X value of 7.5m coke oven blend coal is: X 7.5 =X 6 *(1+25%)=28*(1+25%)=35mm; the upper limit of X value is: X 7.5 =X 6 *(1+25%)=36*(1+25%)=45mm.

[0045] ② The lower limit of the b value of 7.5m coke oven blend coal is: b 7.5 =b 6 *(1+25.33%)=10*(1+25.33%)=12.5%; the upper limit of b value is: b 7.5 =b 6 *(1+25.33%)=36*(1+25.33%)=45.1%.

[0046] ③The length of the 7.5m coke oven is longer than that of the 6m coke oven (18880-15980) / 15980=18.15%, then the lower limit of the maximum fluidity of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com