Support construction having increased structural dampening

A technology for load-bearing structures and load-bearing elements, applied in building components, building structures, bridges, etc., can solve problems such as technical difficulties, implementation and corrosion protection problems, and achieve the effect of easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In the following elaboration, the first involves Figure 1 to Figure 10 .

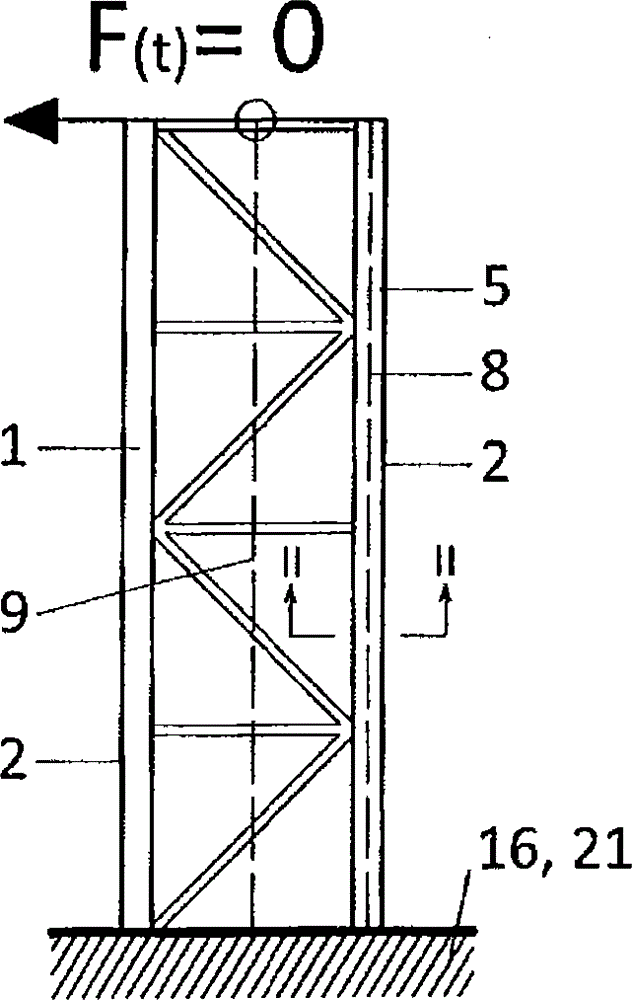

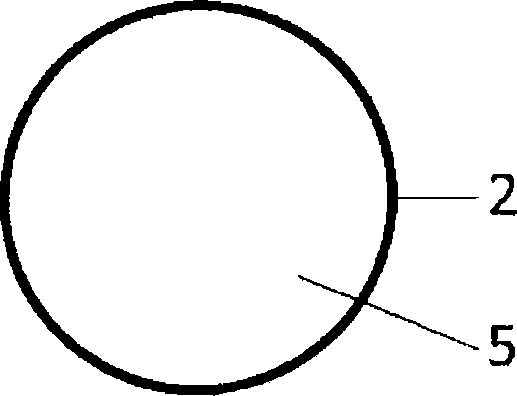

[0075] exist figure 1 The load-bearing structure 1 for absorbing the force F(t) acting at the upper end is shown in the undeformed state (F(t)=0). The load-bearing elements 2 of the load-bearing structure 1 consist of rods and beams. The cavity 5 is located in the carrier element 2 which is designed as a steel tube. The axis of the center of gravity of the support structure 1 is indicated with 9 and the axis of the center of gravity of the support element 2 is indicated with 8 . The foundation 16 serves as an abutment 21 for the load-bearing structure. figure 2 A section through carrier element 2 with cavity 5 is shown.

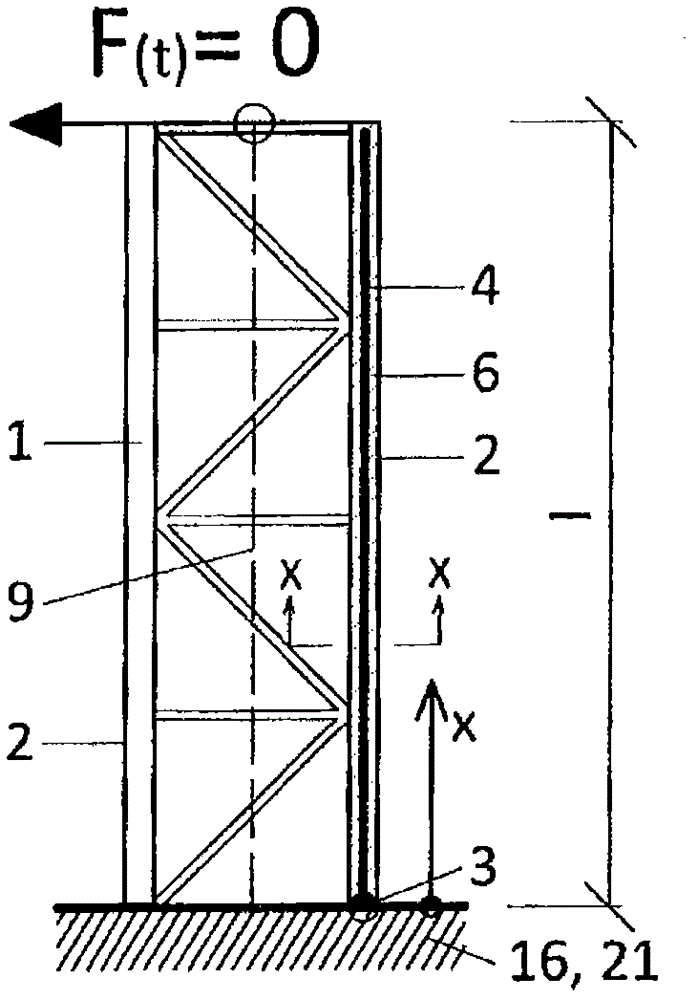

[0076] exist image 3 shown in the figure 1 Section of the load-carrying structure 1 with the rod 4 installed and the remaining volume of the cavity 5 filled with the material 6 . The rod 4 is fastened immovably at the abutment 21 by means of the anchor 3 . For a bett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com