Potato seeder

A planter and potato technology, applied in the field of planters, can solve the problems of inconvenient operation, mismatch of power machines, uneven seeding of seeds, etc., and achieve the effects of convenient operation, reducing the influence of slippage, and ensuring plant spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

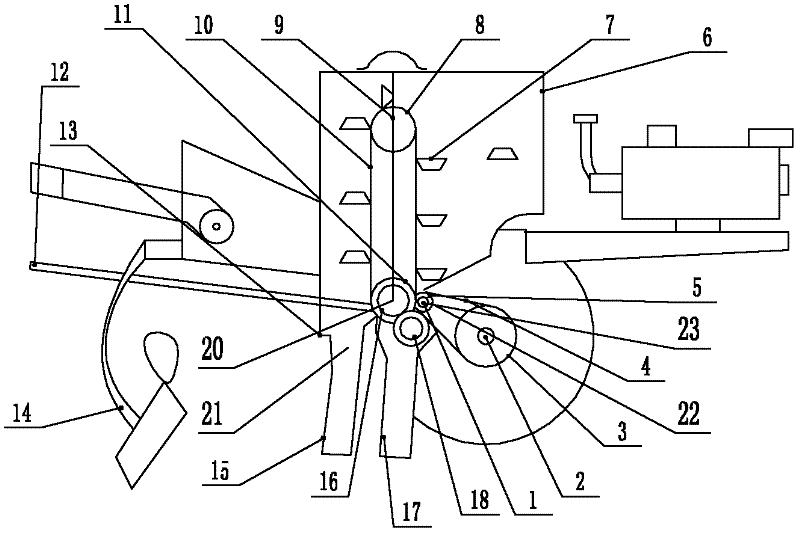

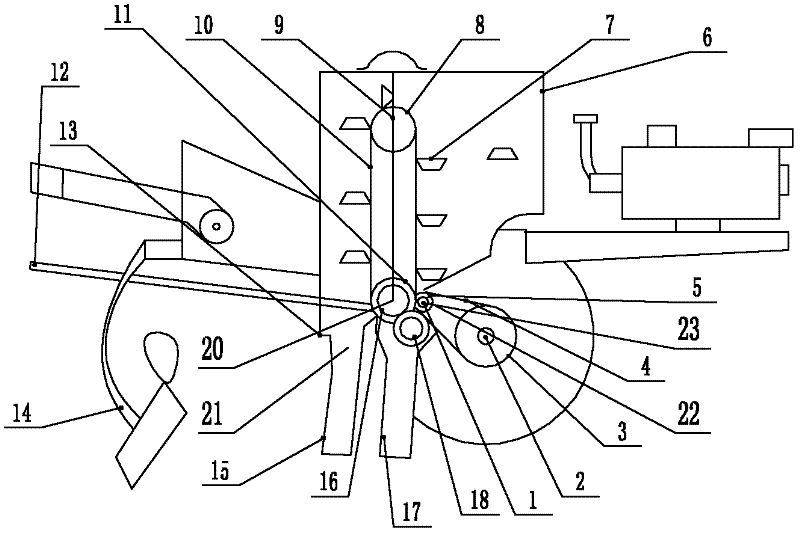

[0015] A potato planter such as figure 1 Shown: it comprises by support base plate 13, support base plate 13 top fixed inside fixed with vertical support 9, the bottom is connected with the support 21 that the seed storage box 6 of lower seed discharge conduit 15 is assembled into, and support base 9 cooperates respectively up and down with The last seed sprocket 8 and the lower seed sprocket 11, the seed chain 10 is coordinated between the upper seed sprocket 8 and the lower seed sprocket 11, and the seed chain 10 is evenly distributed with a seed lifting bowl 7 on the outer circumference of the seed chain 10 , the front portion of the seed storage box 6 is fixed with a ditch opener 14 and a clutch handle 12, the seed chain 10 cooperates with the transmission device 20, and the above-mentioned support 21 cooperates with the half shaft 2 on the right side of the walking tractor;

[0016] Described transmission device 20 is by the transmission chain wheel 3 driven by described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com