Husking rubber roller mechanism for corn husker

A peeling machine and rubber roller technology, which is applied in agricultural machinery and tools, harvesters, threshing equipment, etc., can solve the problems of broken seeds, reduce the processing quality of corn cobs, increase production costs, etc., and achieve the effect of reducing the broken seed rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

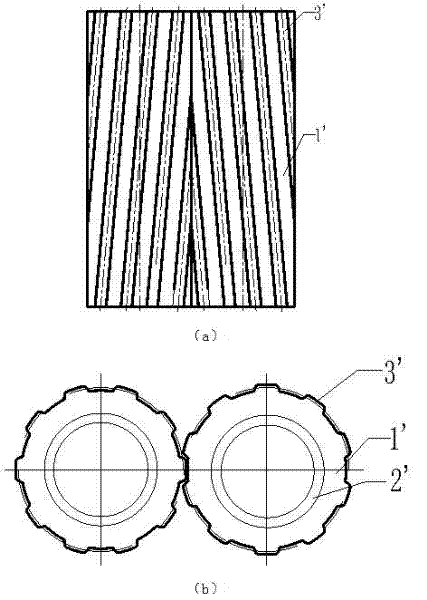

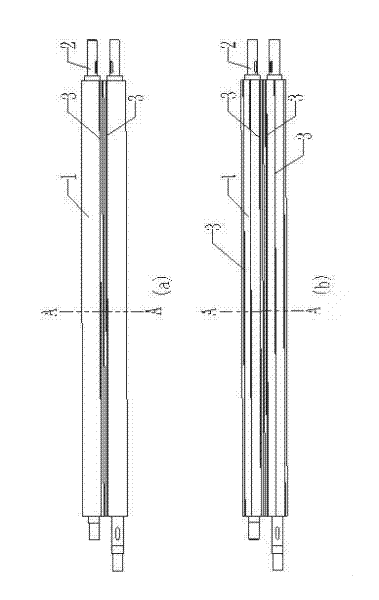

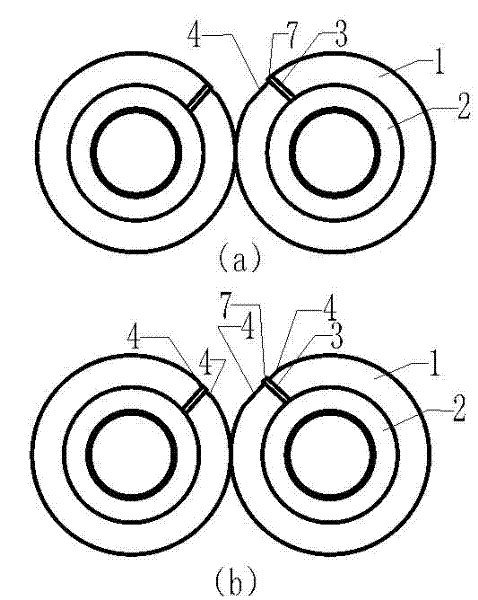

[0028] like figure 2 , 3 As shown in and 4, the peeling rubber roller mechanism of the corn peeling machine includes a roller shaft 2 and a rubber sleeve 1, the rubber sleeve 1 is fixed on the roller shaft 2, the rubber sleeve 1 is cylindrical, and the rubber sleeve 1 is fixed with a longitudinal blade 3, There is a blade edge 4 on the rubber sleeve 1 beside the blade 3, the blade 7 of the blade 3 is flat, the fixed height of the blade 3 is equal to the thickness of the rubber sleeve 1, and the blade 3 is embedded in the rubber sleeve 1 or fixed on the roller shaft 2. On the circumference, the vertical height of the blade edge 7 from the lowest point of the blade edge 4 is 0.3 mm-3.5 mm, and the angle α between the blade edge 4 and the blade 3 is 30 to 130 degrees.

Embodiment 2

[0030] like figure 2 , 3 , 4, 9 and 10, the peeling rubber roller mechanism of the corn peeling machine includes a roller shaft 2 and a rubber sleeve 1, the rubber sleeve 1 is fixed on the roller shaft 2, the rubber sleeve 1 is cylindrical, and the rubber sleeve 1 is fixed with The longitudinal blade 3 has a blade edge 4 on the rubber sleeve 1 on both sides of the blade 3. The blade 7 of the blade 3 is in a sawtooth shape. The fixed height of the blade 3 is equal to the thickness of the rubber sleeve 1. The blade 3 is embedded in the rubber sleeve 1 or fixed On the circumference of the roller shaft 2, the vertical height between the blade edge 7 and the lowest point of the blade edge 4 is 0.3mm-3.5mm, and the angle α between the blade edge 4 and the blade 3 is 30 to 130 degrees. A concave spiral line 6, the section of the spiral line 6 is arc-shaped.

Embodiment 3

[0032] like figure 2 , 3 , 4, 9 and 10, the peeling rubber roller mechanism of the corn peeling machine includes a roller shaft 2 and a rubber sleeve 1, the rubber sleeve 1 is fixed on the roller shaft 2, the rubber sleeve 1 is cylindrical, and the rubber sleeve 1 is fixed with Three longitudinal blades 3, the rubber sleeve 1 beside each blade 3 has a blade edge 4, the blade 7 of the blade 3 is flat, the fixed height of the blade 3 is equal to the thickness of the rubber sleeve 1, and the blade 3 is embedded in the rubber sleeve 1 or fixed on the circumference of the roller shaft 2, the vertical height of the blade edge 7 from the lowest point of the blade edge 4 is 0.3mm-3.5mm, the angle α between the blade edge 4 and the blade 3 is 30 to 130 degrees, the rubber A concave helix 6 is formed on the cover 1, and the section of the helix 6 is arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com